A tower crane is construction equipment used to lift and transport heavy materials to various heights on a construction site. It consists of a vertical tower, a horizontal jib, and a counterweight. The tower provides the crane’s height, while the jib is a long arm that rotates horizontally. The counterweight balances the load lifted by the crane.

How Does a Tower Crane Work?

A tower crane operates by lifting and transporting heavy objects using a hoist hook or other gripping devices. The general working process involves lifting, moving, lowering, and returning to its original position. The hoisting mechanism lifts the load from its pickup point, while the traveling, slewing, or luffing mechanism moves the load to its desired location, and then returns to its original position.

The Crane’s Operation Involves Several Key Components:

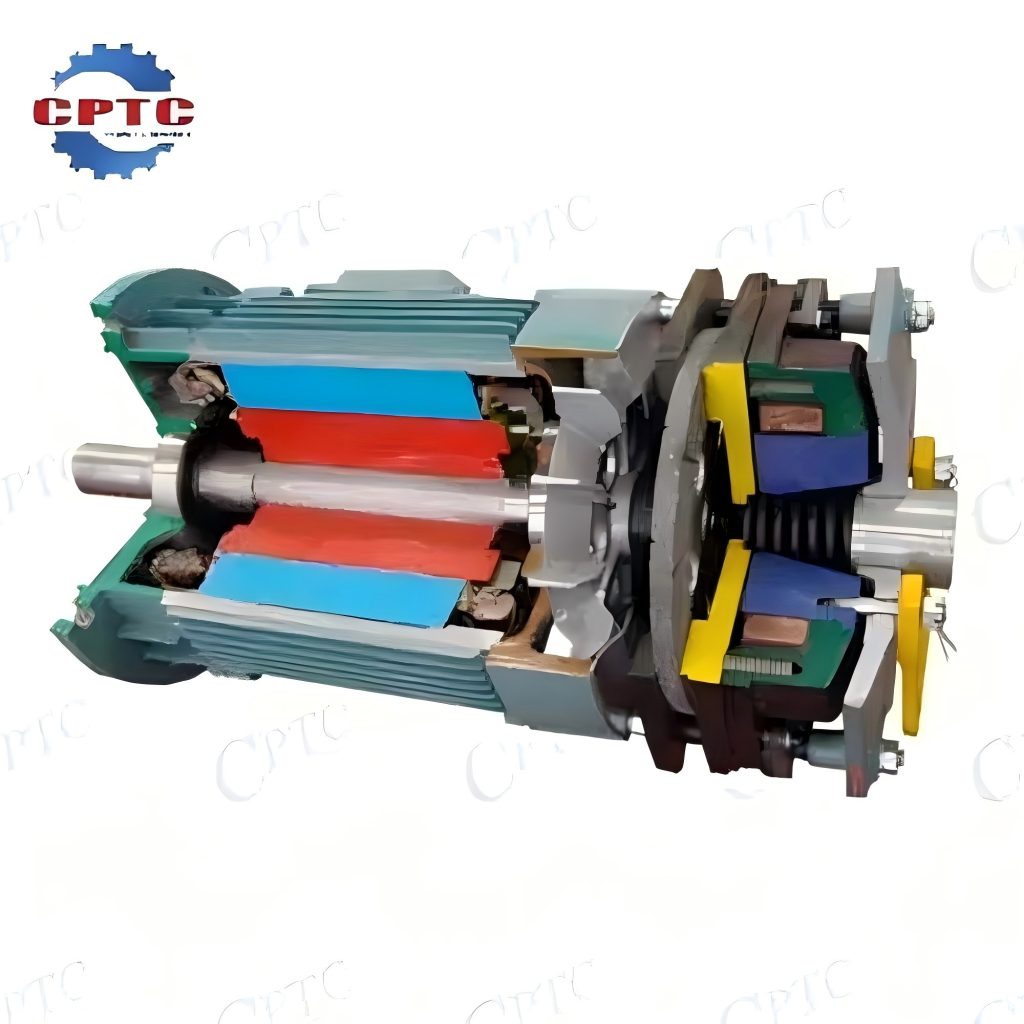

Hoist Mechanism

The hoist mechanism, responsible for lifting and lowering loads, can be implemented through various systems. The most common is the drum and wire rope system, which utilizes a motorized drum to wind or unwind a wire rope. For precise control and heavy lifting, hydraulic hoists employ hydraulic cylinders. Electric chain hoists, powered by electric motors, offer a compact and efficient solution for smaller loads.

Slewing Mechanism

The slewing mechanism, enabling the jib to rotate horizontally, comprises several key components. A large, circular slewing ring, often equipped with gearboxes to reduce torque, allows the jib to swivel. An electric motor powers the slewing ring, driving the rotation of the jib. Slewing brakes are essential for keeping the jib stationary when not in operation.

Counterweight

The counterweight, a crucial component of the tower crane, balances the load on the jib, preventing the crane from tipping over. It is often adjustable to accommodate different load capacities and jib configurations and is typically made of concrete or steel.

Tower Structure

The tower structure, which provides vertical support and houses the crane’s machinery, can be constructed in various ways. Lattice boom towers, composed of lattice-like structures, offer flexibility and ease of assembly. Self-erecting towers can be assembled without external assistance, making them ideal for remote locations. Guyed towers, supported by guy wires anchored to the ground, provide stability.

6 Reasons to Choose Original Tower Crane Parts

As a high-risk machine on construction sites, any issue with a tower crane can potentially jeopardize the safety of personnel on the project. Replacing genuine parts with counterfeit ones can lead to catastrophic consequences. If you’re considering these cheaper imitation parts, here are six compelling reasons why you should avoid them at all costs:

1. Guarantee Equipment Performance

Original parts, designed and manufactured to precise specifications, ensure optimal performance of the crane. Well-functioning components contribute to increased productivity and reduced downtime. Additionally, genuine parts are more reliable and less prone to failures, minimizing disruptions to construction schedules.

Manufacturers of counterfeit components often misleadingly claim that their versions have the same brand and quality as genuine parts. While the appearance may be very similar, it is unlikely that their components meet the original manufacturer’s specifications and quality standards, or maintain their standards for continuous improvement. Consequently, they pose a significant safety risk to cranes equipped with counterfeit products.

2. Improve Work Efficiency

Original parts are designed for easy installation, reducing downtime and accelerating project timelines. High-quality original parts require less frequent maintenance, saving time and labor costs. Furthermore, genuine parts ensure smooth and efficient operation of the crane, minimizing delays and maximizing productivity.

On the other hand, counterfeit components can lead to premature wear of other parts, as they are manufactured by companies or workshops that may not understand or have access to the overall specifications of the crane.

3. Ensure Safety

Original parts are rigorously tested to meet safety standards, minimizing the risk of accidents and injuries. Reliable components contribute to a safer working environment by preventing unexpected failures. Additionally, using genuine parts helps ensure compliance with local and international safety regulations.

Genuine parts allow you to benefit from high-quality, professional technical support, which is a service you can’t get from anonymous internet vendors who are likely to offer parts for a wide range of machinery from a wide range of manufacturers.

4. Save Costs

Original parts offer a longer lifespan, reducing the frequency of replacements and repairs, and consequently lowering maintenance costs. Employing inferior parts can result in equipment failure and substantial repair expenses. Conversely, investing in genuine parts can yield substantial long-term cost savings. Avoid the short-sighted approach of compromising quality for immediate cost savings.

5. Comprehensive After-sales Service

Original part suppliers provide expert technical support to address any issues or questions. Easy access to genuine parts minimizes downtime and maintenance delays. Additionally, original parts often come with warranties, providing added peace of mind.

Only genuine parts are eligible for the crane manufacturer’s warranty. The manufacturer shall not be responsible for any damage caused by cranes equipped with counterfeit parts, nor shall they assume any liability.

6. Brand Assurance

Reputable brands prioritize quality and reliability in their products, ensuring genuine parts maintain the value of your tower crane. Such brands also offer excellent customer support and service.

Other Considerations

To ensure the longevity and safety of your tower crane, it’s crucial to purchase genuine parts from authorized dealers, conduct regular maintenance and inspections, employ qualified technicians, provide comprehensive safety training to operators and maintenance personnel, and establish a well-defined emergency plan to respond to accidents or equipment failures.

As a well-established company in the construction equipment industry since 2006, CPTC has been providing a comprehensive range of essential tower crane parts. Our unparalleled product knowledge and dedicated service ensure you receive expert procurement advice.

Related Products

Motor for Construction Hoist

Gentle braking (by the…

Heavy Duty Pipe Clamp & Heavy Duty Coupler

Alimak replacement parts/ Alimak compatible parts

Durability

OEM part…

Sew Motor & Sew Gearbox

SEW drive experts

Customized and efficient

Innovative and energy-saving

Construction Hoist Mast Section

Simple operation

Stable performance