CNC Making Product

CPTC also offers CNC Making Product services, including Complex Parts Making by CNC and Mold Making by CNC. Rapid prototyping through CNC machining provides a high-speed, high-precision, and powerful rapid parts manufacturing solution.

Our company offers rapid prototyping and volume production services to customers across a diverse range of industries, including industrial automation, machinery, and manufacturing. We invite you to contact us with any questions regarding our products and services.

Mold Making by CNC

Mold manufacturing

High automation

Labor savings

Complex Parts Making by CNC

High efficiency

Versatility

Wide applications

| Benefits of CNC Making Product

- Customized Services: We offer a wide range of surface treatments tailored to solid metal and plastic components, ensuring precise adherence to design specifications.

- Rapid Prototyping: CNC machining’s versatility across a diverse range of materials makes it ideal for rapid prototyping, including the creation of jigs and molds.

- Quality Control: Our quality assurance department meticulously implements stringent quality control procedures.

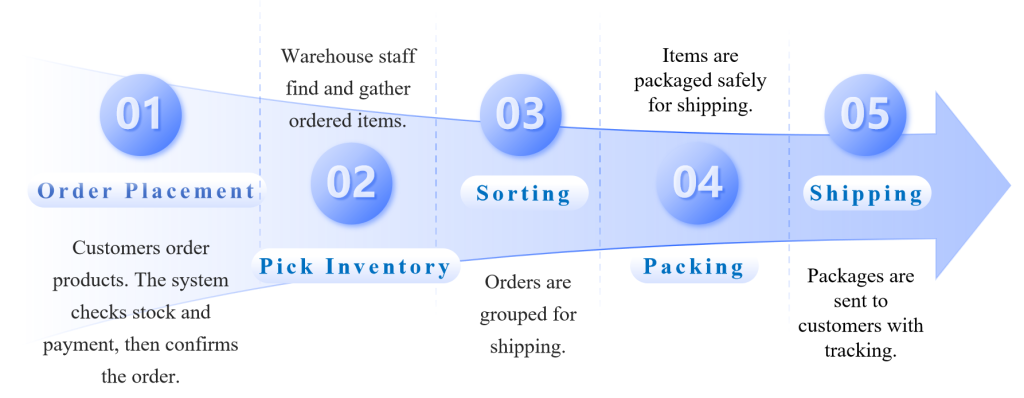

| Ordering Process

| Packing & Delivery