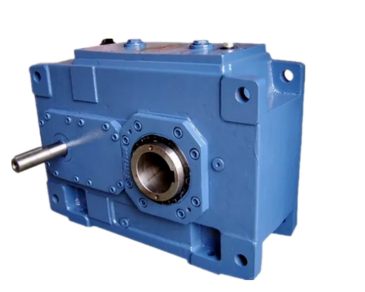

Construction hoists are essential equipment for transporting materials and personnel to various levels of a construction site. The gearbox, a critical component within the hoist system, houses gears that play a vital role in transmitting power and reducing speed. However, gear failures can lead to significant downtime, safety hazards, and increased maintenance costs. This article delves into the common causes of gear failures in hoist gearboxes, along with preventive measures and maintenance strategies.

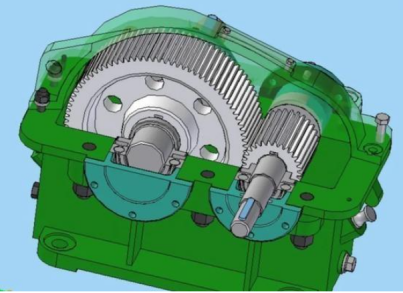

What is the Gear in a Construction Hoist Gearbox?

The gear of the construction hoist reduction box is an important part of the construction hoist transmission system. It mainly plays the role of reducing speed and increasing torque, converting the high speed and low torque of the motor into low speed and high torque, thereby driving the lifting movement of the hoist.

Working Principle:

The gearbox in a construction hoist is a mechanical device that reduces the speed of a rotating shaft while increasing its torque. This reduction in speed is achieved through a series of gears with different diameters. When a motor drives the input shaft, the gears within the gearbox mesh together, transferring power and reducing the rotational speed. The output shaft, connected to the hoist drum or other components, rotates at a slower speed but with increased torque.

Components:

- Gear Teeth: The interlocking teeth on the gears are responsible for transmitting power and reducing speed.

- Gear Housing: Encloses the gears and bearings, protecting them from external contaminants and providing structural support.

- Bearings: Support the rotating shafts and reduce friction.

- Shafts: Transmit power between the gears and other components.

- Lubricant: Reduces friction and wear between the gears and bearings.

Common Causes of Gear Failures in Hoist Gearboxes

There may be many reasons for gearbox gear failure, which requires us to carefully inspect and maintain the gears. If you encounter a gearbox gear failure, you should first find out the specific cause and then take appropriate measures. In this way, we can better ensure the normal operation of the gear and extend the service life of the gearbox. The following will introduce several common reasons for the failure of the construction hoist reducer gear:

Surface Fatigue of Reducer:

When inspecting the gear of a construction hoist reducer, attention should be paid to the three progressive stages of surface fatigue. If the first stage is not addressed, it will develop into the second stage, and if still left unattended, it will further progress to the third stage.

| Stage | Formation Mechanism |

| Pitting | Pitting often occurs around the pitch line. The surfaces of new gear and chain pairs have a certain degree of roughness. Around the pitch line, the direction of sliding contact between the two gear and chain pairs changes, resulting in the thinnest oil film, the smallest contact area, and only dynamic friction without sliding friction. This generates a large contact pressure stress, causing the deformation or shedding of small protruding peaks on the surface around the pitch line of the new gear, resulting in pitting. This type of pitting usually heals after the running-in period of the gear and chain. |

| Number of Cycles Exceed a Certain Limit | When the contact stress and number of cycles exceed a certain limit, small cracks will form on the two tooth surfaces. The contact stress is a pulsating cyclic stress that changes with time. As the number of cycles increases, the cracks gradually expand, causing the metal particles between the cracks to peel off and form pitting fatigue on the tooth surface. |

| Spalling | Spalling is formed by the connection of many small pitting pits to form large holes. In this case, the speed of spalling of the gear and chain should be monitored to arrange for the replacement of new gear and chain, thereby avoiding equipment failure caused by damage to the gear and chain. |

Supervision and Gear Surface Wear:

When the gear and chain in a construction hoist reducer mesh together, they rub against each other not just at the center point but also at other places. This rubbing causes wear and tear on the teeth. A little bit of wear is normal, especially when the gear and chain are new. But too much wear means there’s a problem, like not enough oil or the shafts aren’t lined up straight. The first sign of too much wear is small scratches on the tips of the teeth. These scratches can get bigger and deeper, or even cause small holes in the teeth.

- Wear: Gradual loss of material from the gear surface due to friction.

- Misalignment: Improper alignment of the gears can lead to uneven wear and accelerated failure.

- Inadequate Lubrication: Insufficient or contaminated lubricant can increase friction and wear.

Plastic Deformation of Reducer:

The plastic deformation of the metal surface of the gear and chain in a construction hoist reducer is primarily caused by excessive load, especially impact loads.

- Excessive Load: Overloading the gearbox can cause the gears to deform, leading to reduced efficiency and premature failure.

- Impact Loads: Sudden shocks or vibrations can induce plastic deformation, especially in weaker materials.

Fracture of Gear and Chain:

While not very common, this situation is the most severe as it can cause complete failure of the gear and chain in the reducer, often occurring at the tooth root. Gear and chain breakage is generally caused by excessive load or metal fatigue.

- Material Fatigue: Repeated stress cycles can weaken the material, leading to cracks and eventual fracture.

- Overload: Exceeding the gear’s load capacity can cause catastrophic failure.

- Manufacturing Defects: Poor quality control or manufacturing defects can weaken the gear’s structure.

Contamination of Reducer Lubricant:

Any abrasive contaminants can cause premature wear. Fine abrasives can give the gear and chain a polished appearance, but the tooth profile will be altered. Coarser abrasives will produce scratches, and larger contaminants, such as screws, nuts, or gear fragments, can cause pitting on the gear and chain surface.

- Water Ingress: Water can degrade the lubricant’s properties and accelerate corrosion.

- Contaminant Particles: Dirt, dust, and metal particles can damage the gear surfaces and bearings.

- Oxidation: Exposure to air can cause the lubricant to oxidize, reducing its effectiveness.

Interference of Gear and Chain:

Misalignment of the axes and deviations in the profile or backlash of the gear and chain can cause interference between the gears. This is when the tip of the driving gear meshing with the driven gear engages at the separation point of the meshing cycle.

- Improper Alignment: Misaligned gears can cause excessive friction and wear.

- Foreign Object Damage: Debris or foreign objects can damage the gears and chain.

- Excessive Chain Tension: Overtightening the chain can increase stress on the gears and bearings.

Prevention and Maintenance Measures

- Regular Inspection: Conduct routine inspections to identify and address potential issues early.

- Proper Lubrication: Use the recommended lubricant and ensure adequate lubrication levels.

- Avoid Overloading: Operate the hoist within its rated capacity.

- Prevent Contamination: Keep the gearbox clean and protected from environmental contaminants.

- Monitor Vibration and Noise: Excessive vibration or noise can indicate impending failure.

- Align Gears and Shafts: Ensure proper alignment to minimize wear and improve efficiency.

- Replace Worn Components: Replace worn or damaged gears, bearings, and seals promptly.

- Train Operators: Provide proper training to operators to avoid misuse and abuse of the hoist.

Final Words

By understanding the common causes of gear failures in hoist gearboxes and implementing effective preventive maintenance strategies, it is possible to significantly reduce downtime, improve safety, and extend the lifespan of these critical components. Regular inspections, proper lubrication, and avoiding overloading are essential for maintaining the reliability and efficiency of construction hoists.

Related Products

Wind Speed Anemometer

High-precision measurement

High reliability

Easy installation

Potain Replacement Parts

Potain replacement parts;

Potain compatable parts.

Part number: C-61406; B-70406;…

Tower Crane Load Limit

Safe and Reliable

Simple Operation

High Precision

Tower Crane Limit Switch

Multiple functions

Intuitive operation