Suspended platforms, also known as aerial work platforms or suspended access platforms, are widely used in construction, maintenance, and industrial applications. They provide a safe and efficient way to access elevated areas. However, despite their safety features, unexpected incidents can still occur during operation. Therefore, it is crucial to understand how to properly handle these situations to avoid accidents caused by improper operation or failure.

This article will discuss common issues encountered with suspended platforms and provide practical solutions to enhance safety.

1. What is a Suspended Platform?

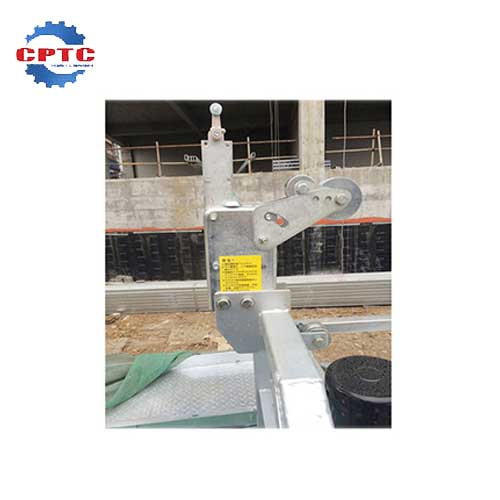

A suspended platform is a temporary work platform that is suspended from a fixed structure or building. It typically consists of a platform, a hoisting system, and safety devices. The hoisting system is used to raise and lower the platform to the desired height. Safety devices, such as safety locks and emergency stop buttons, are essential to prevent accidents.

Suspended platforms are highly adaptable, efficient solutions for elevated work. They offer high construction efficiency, easy lifting, and vertical placement, and require minimal physical effort. Widely used in the installation of billboards, construction structures, window cleaning, exterior renovations, painting and plastering, bridges, chimneys, silos, and other high-rise buildings.

2. Common Faults and Solutions of Suspended Platforms

As crucial equipment for high-altitude operations like exterior wall insulation coating, suspended platforms are susceptible to various unexpected incidents during operation. Operators should remain calm and strictly follow emergency procedures to take appropriate measures, ensuring both their safety and smooth operation. The following summarizes the common faults of the hanging basket and their corresponding solutions:

(1) The Suspended Platform Slides Down When Stationary

- Possible causes:

- Brake failure: The brake may be malfunctioning or improperly adjusted.

- Steel cable slack: The steel cable tension may be insufficient to hold the platform in place.

- Hoist malfunction: Internal mechanical issues within the hoist can cause the platform to slide.

- Solutions:

- Inspect and adjust the brake to ensure it is functioning properly.

- Check the steel cable tension and adjust it as needed.

- Conduct a thorough inspection of the hoist mechanism to identify and address any mechanical problems.

(2) The Hoist and Motor on One Side of the Suspended Platform Do Not Work, or the Electromagnetic Brake is Hot and Smoking

- Possible causes:

- Electrical issues: The motor may be burned out, overloaded, or have loose connections. The control circuit might be short-circuited, open-circuited, or have damaged components.

- Brake malfunction: The electromagnetic brake could be stuck or have a damaged coil.

- Solutions:

- Inspect and replace the motor if it is damaged.

- Check the control circuit for any electrical faults and repair them.

- Examine the electromagnetic brake for any signs of damage or malfunction and replace it if necessary.

(3) There is an Abnormal Noise from the Suspended Platform Machine

- Possible causes:

- Bearing wear: Worn bearings can cause friction and noise.

- Gear wear: Damaged gears can produce abnormal sounds.

- Foreign objects: Foreign debris can enter the machine and cause noise.

- Solutions:

- Inspect and replace worn bearings.

- Check and replace damaged gears.

- Clean out any foreign objects from the machine.

(4) The Working Steel Cable Cannot Enter the Suspended Platform

- Possible causes:

- Cable entanglement: The cable may be tangled or stuck.

- Guide wheel damage: A damaged guide wheel can prevent the cable from entering correctly.

- Cable damage: The cable itself may be damaged or worn.

- Solutions:

- Carefully untangle the cable if it is stuck.

- Inspect and replace any damaged guide wheels.

- Examine the cable for damage and replace it if necessary.

(5) The Suspended Platform is Tilted

- Possible causes:

- Uneven cable length: If the cables on both sides are not of equal length, the platform will tilt.

- Structural issues: Problems with the platform’s structure or the building can cause unevenness.

- Load imbalance: An unbalanced load on the platform can also lead to tilting.

- Solutions:

- Ensure that the cables are of equal length.

- Inspect the platform’s structure and the building for any structural issues.

- Redistribute the load on the platform to ensure it is balanced.

(6) The Working Steel Cable of the Suspended Platform is Abnormally Worn

- Possible causes:

- Excessive friction: Friction between the cable and the guide wheels or other components can cause wear.

- Poor cable quality: A low-quality cable may be more susceptible to wear.

- Overloading: Exceeding the platform’s weight capacity can put excessive strain on the cable.

- Solutions:

- Reduce friction by ensuring proper alignment and lubrication.

- Replace the cable with a higher-quality one if necessary.

- Avoid overloading the platform.

(7) The Safety Lock of the Suspended Platform Cannot Lock the Steel Cable

- Possible causes:

- Safety lock malfunction: The safety lock mechanism may be damaged or defective.

- Cable damage: A damaged or worn cable may prevent the safety lock from engaging properly.

- Improper installation: The safety lock may not be installed correctly.

- Solutions:

- Inspect and repair or replace the safety lock if it is malfunctioning.

- Replace the cable if it is damaged.

- Ensure that the safety lock is installed correctly according to the manufacturer’s instructions.

(8) The Suspended Platform Cannot Work

- Possible causes:

- Power failure: The power supply to the platform may be interrupted.

- Control system malfunction: The control system may be damaged or not functioning properly.

- Mechanical failure: There may be a mechanical issue within the platform’s components.

- Solutions:

- Check the power supply and ensure it is working properly.

- Inspect the control system for any faults and repair them.

- Diagnose and repair any mechanical issues within the platform.

3. Daily Maintenance of the Suspended Platform

Regular maintenance is crucial to ensure the safe and reliable operation of a suspended platform. Here are some essential daily maintenance tasks:

· Daily Maintenance: At the end of each workday, thoroughly clean the suspended platform, steel ropes, and suspension mechanisms. Remove all debris, paint, and any adhering mortar or impurities.

· Weatherproofing: Implement waterproofing and moisture-proofing measures for the aerial electric hoist, especially the electrical system, to prevent electrical short circuits caused by moisture or water ingress.

· Cable Storage: Coil and secure any excess steel cable on the ground. After disassembling the suspended platform when it is not in use, coil all ropes and cables, disassemble components and arrange them in an orderly manner, and store connection parts properly to prevent mildew, corrosion, deformation, and loss.

· Safety Rope Maintenance: After each use, apply anti-rust lubricant to the spring of the self-locking device on the safety rope to ensure smooth operation.

· Gearbox Lubrication: The gearbox and transmission should be lubricated with new oil after the first three months of use. Subsequently, add lubricant once a month and replace it every six months.

· Safety Lock Lubrication: Lubricate the moving parts of the electric hoist safety lock once a month.

· Electrical Maintenance: Keep electrical components, wiring connections, and areas prone to electrical short circuits dry and clean. Avoid oil stains or dirt accumulation.

· Inspection and Repair: If any faults or abnormalities are detected during safety inspections, routine inspections, or operation, immediately stop using the suspended platform and have it inspected by a qualified technician. Strictly prohibit the use of a faulty aerial electric hoist.

4. Final Words

Suspended platforms are valuable tools in various industries, but they require proper maintenance and troubleshooting to ensure safe and efficient operation. By understanding common faults and following the recommended solutions, you can minimize downtime and prevent accidents. Regular maintenance is essential to prolong the lifespan of your suspended platform and ensure its continued reliability.

CPTC has been deeply involved in the construction industry for several years and has rich production experience and strong technical strength. If you encounter any problems with the use of the suspended platform, please feel free to contact us.

Related Products

Bronze & Brass Worm Wheel

Precise control for smooth operation

Simple…

Brake Rectifier Modulek

Compact Size

Convenient Wiring

Durable Heat Sink Material

Stable Performance

Safety Rope

Lightweight and Portable

Durable and Long-lasting

Construction Platform

With a lightweight…