Suspended platforms, also known as gondola lifts or hanging scaffolds, are essential tools in modern construction, allowing workers to access and work on vertical surfaces safely and efficiently. These platforms are typically comprised of a working platform suspended from a hoisting mechanism that travels along vertical guide rails.

This guide will provide a comprehensive overview of maintenance and care procedures for suspended platforms, focusing on key components and best practices.

What is a Suspended Platform?

A suspended platform is a temporary work platform designed for accessing and working on vertical surfaces such as building facades, bridges, and industrial structures. It typically consists of the following key components:

- Working Platform: The platform itself, where workers stand and perform their tasks.

- Hoist: The motorized mechanism that raises and lowers the platform.

- Safety Locks: Independent braking systems that engage automatically in case of emergencies.

- Steel Ropes: High-strength steel ropes that support the platform and connect it to the hoist.

- Guide Rails: Vertical rails that guide the platform’s movement and provide stability.

- Electrical System: Controls the hoisting mechanism and other platform functions.

- Control Panel: A control unit for operating the platform, including controls for raising, lowering, and emergency stops.

The Importance of Maintenance and Care for Suspended Platforms

Regular maintenance and care are crucial for ensuring the safe and efficient operation of suspended platforms. Neglecting maintenance can lead to:

- Safety Hazards: Malfunctioning components, such as worn-out ropes, faulty brakes, or electrical problems, can pose significant safety risks to workers.

- Reduced Efficiency: Equipment malfunctions and breakdowns can cause delays and disruptions to work schedules, impacting project timelines and budgets.

- Increased Costs: Unexpected repairs and replacements can be costly, significantly increasing the overall project expenses.

- Legal and Regulatory Issues: Non-compliance with safety regulations and industry standards can result in fines, penalties, and legal liabilities.

A Comprehensive Maintenance Guide for Suspended Platforms

Upon purchasing a suspended platform, the owner is obligated to assume responsibility for its maintenance and upkeep in accordance with the user manual. This not only preserves the overall performance and extends the service life of the equipment but also ensures the safety of personnel. Regular maintenance and inspections should be conducted as per the prescribed schedule.

- Maintenance: This does not involve the replacement of parts and is carried out by the operator at regular intervals. It includes cleaning and general upkeep of the platform. Daily inspections and maintenance of the suspended platform are essential.

- Inspection: Conducted by a qualified technician, this involves a thorough examination of the entire platform, replacement of worn parts, and damaged components, as well as replenishing lubricants.

- Overhaul: A comprehensive service performed by a qualified technician that involves disassembling, cleaning, and reassembling major components. Worn-out or damaged parts are replaced, lubricants are replenished, and the structural components are repainted.

Maintenance and Care of the Hoist

Cleaning: Regularly clean the hoist surface and working steel ropes to prevent foreign objects from entering the infeed and outfeed openings, which could damage internal components.

Lubrication: Add or replace the specified lubricant as required by the user manual. The hoist reduction system is lubricated with gear oil, which should be replaced every 6-12 months depending on usage.

Operation and Protection: Before operation, always conduct a no-load run to check for any abnormal noises or odors. After operation, cover the hoist to prevent it from being exposed to rain, debris, or other contaminants. Avoid collisions during installation, transportation, or use to prevent damage to the housing.

Troubleshooting: If any abnormal conditions occur, such as unusual noises, odors, or excessive heat, stop using the hoist immediately and contact a qualified technician for repair.

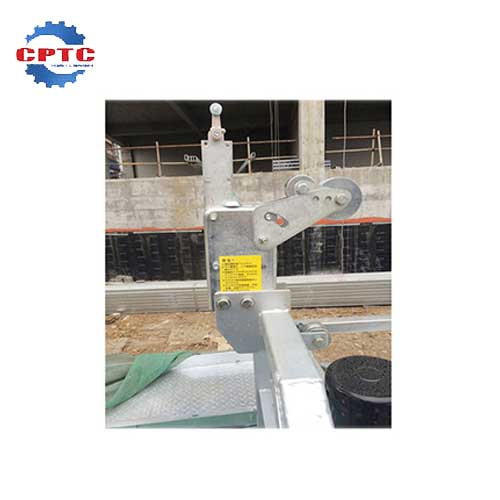

Maintenance and Care of the Safety Locks

Regular Cleaning and Inspection:Regularly clean the safety lock surface and safety cable to remove debris. Pay close attention to the safety lock’s protective measures to prevent foreign object entry.

Inspect the locking function before each operation. Protect the safety lock from rain, snow, and debris after operation.

Recalibration Schedule: Recalibrate the safety lock every 12 months from the date of manufacture. Submit a request to the dealer or manufacturer for professional maintenance and recalibration.

Maintenance and Care of the Steel Rope

- Installation: After installation, the remaining steel rope beneath the hoist should be bundled into a coil and elevated approximately 20cm above the ground.

- Wire Rope Clamp Damage: If localized damage or fatigue is observed on the wire rope clamps, the entire rope end should be discarded and re-secured with a wire rope clamp according to the instructions. Wire ropes should not be spliced.

- Regular Inspection and Cleaning: Regularly inspect the surface of the wire rope, promptly clean any attached contaminants, and promptly identify and address any signs of localized defects.

- Broken Wire Handling: For wire ropes with broken wires that have not yet reached the discard criteria, the broken ends should be inserted into the rope core. Wire ropes cannot be repaired. For wire ropes that meet the discard criteria, replace them promptly.

- Storage and Transportation: During storage and transportation, the wire rope should be coiled into a disk with a diameter of approximately 60cm, and no heavy objects should be placed on top to avoid bending or localized flattening.

Maintenance and Care of the Structural Components

Structural components include the suspension mechanism, suspended platform, and electrical box housing.

- Inspection and Tightening: Regularly inspect connecting and fastening components, and tighten any loose parts promptly. If weld cracks or component deformation is found, promptly contact a professional maintenance technician for repair using appropriate techniques.

- Cleaning and Surface Protection: After operation, promptly clean the surface of any dirt or debris. Avoid using sharp tools to scrape vigorously, and take care to protect the surface coating. If the coating peels off, repair it promptly to prevent rust.

- Handling and Installation: During handling and installation, handle with care and avoid strong collisions or forceful prying to prevent permanent deformation.

Maintenance and Care of the Electrical System

- Electrical Box Cleanliness: Keep the electrical box clean and free of debris. Do not place tools or other materials inside the box.

- Impact Protection: Avoid any external force impact on the electrical box, limit switches, and electrical cables.

- Cable Management: Securely tie the suspended power cable to the suspended platform structure, avoiding direct tension on the plug. If the cable length exceeds 100 meters, take measures to protect the cable against tension.

- Electrical Connection Inspection: Regularly inspect electrical connections for looseness and tighten any loose connections promptly. If any electrical components are damaged or if an electrical fault occurs, promptly contact a qualified technician for troubleshooting.

- Post-Work Procedures: After completing the work, immediately cut off the power, lock the electrical box door, and properly cover the electrical box.

4. Standard Inspection Intervals for Suspended Platforms

The frequency of inspections will vary depending on factors such as the intensity of use, environmental conditions, and local regulations. However, general guidelines for inspection intervals include:

- Daily Inspections: Before each work shift, conduct a brief visual inspection of all major components for any obvious signs of damage or wear.

- Weekly Inspections: Perform more thorough inspections, including functional tests of all safety systems.

- Monthly Inspections: Conduct in-depth inspections of all components, including detailed checks of the hoist, safety locks, and electrical systems.

- Annual Inspections: Conduct comprehensive annual inspections by qualified professionals, including thorough testing of all components and safety systems.

Choose CPTC’s Suspended Platforms for Your Aerial Work

These methods are derived from the daily maintenance practices of our platform operators and are a summary of our experience in electric platform operations. We hope to offer valuable guidance to those involved in maintaining electric platforms.

As a leading manufacturer of suspended platforms, CPTC offers a wide range of high-quality, innovative solutions. Our platforms are designed with safety and efficiency in mind, incorporating the latest technology and engineering to meet your elevated work requirements.

Related Products

Nylon Splitter

Durable and Long-lasting

Brake Rectifier Modulek

Compact Size

Convenient Wiring

Durable Heat Sink Material

Stable Performance

Suspended Platform Safety Lock

Easy to Operate and Use

Made…

Worm Wheel

Precise control for smooth operation

Simple…