Conductor Bar System

- Compact design, space-saving, easy to install and maintain;

- Stability and high conductivity;

- Flexible, insulated and safe;

- Aluminum alloy protection, corrosion resistance, and long life.

Product Description

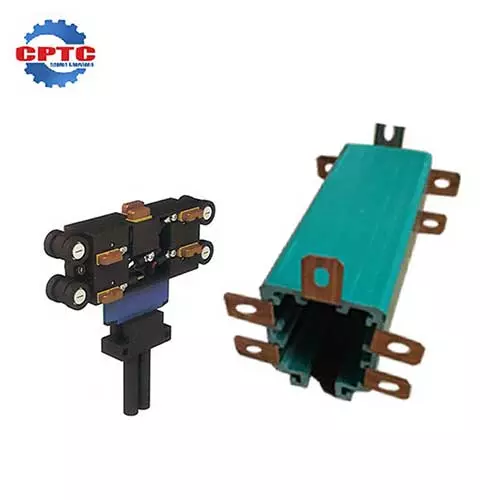

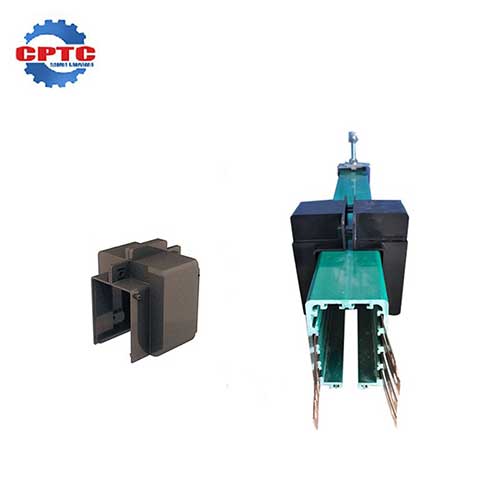

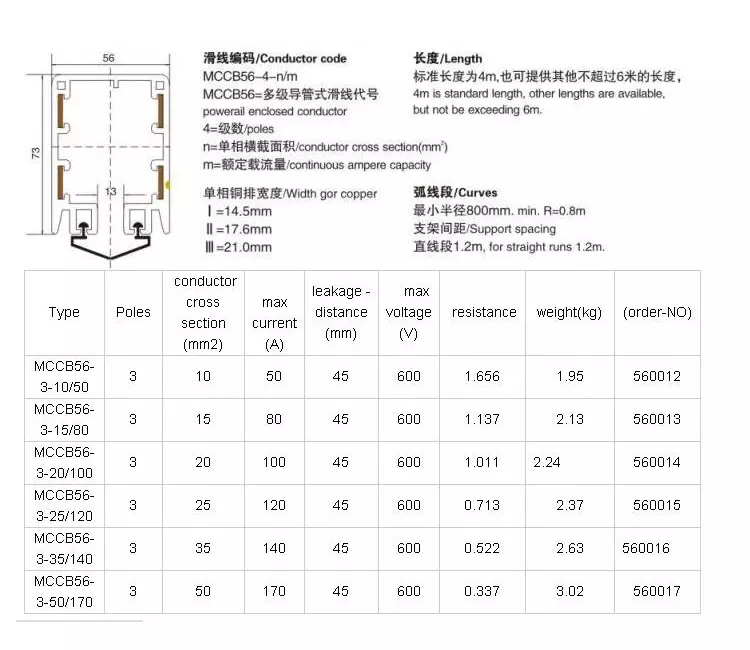

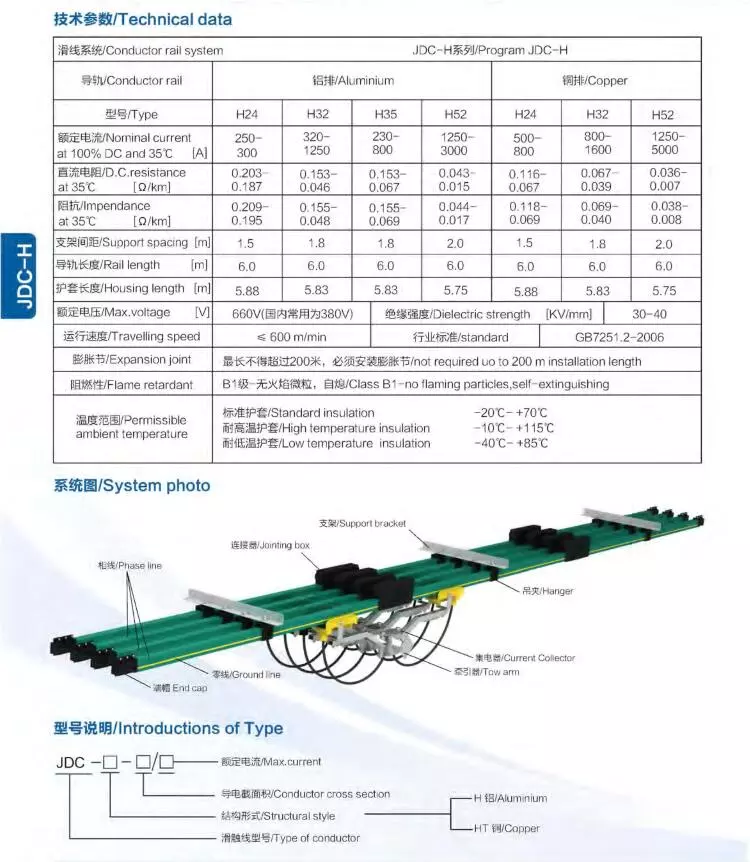

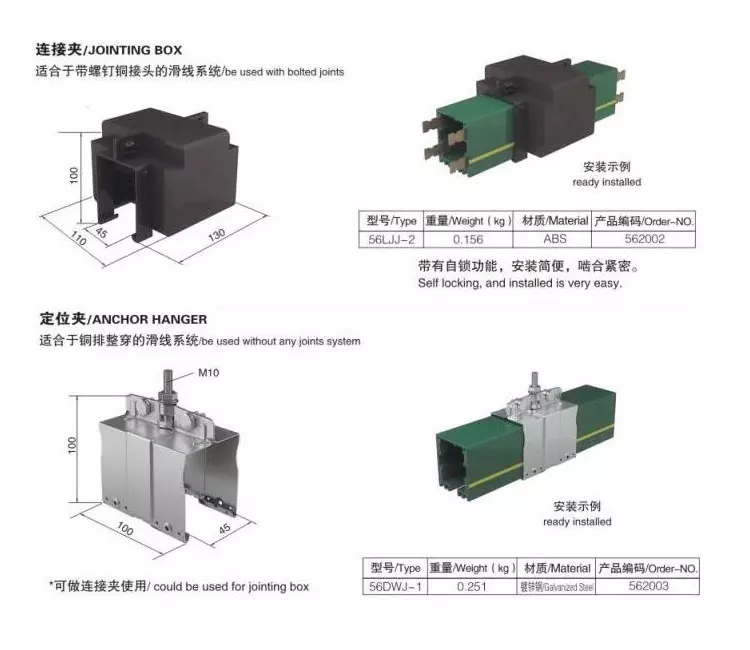

The conductor bar system( insulated conductor rail, conductor bar, power rail, bus bar for construction hoist) is one kind of CPTC’s popular construction hoist electrical parts. It is a power rail, protected from contact ( IP 24 ), for indoor and outdoor plants. They are conductor lines in a rigid green PVC housing with different copper cross sections for rated currents of 35A-170A. The current collectors, running in ball bearings, are guided by the housing. The main is transferred by spring-stored carbon brushes.

|Features of Conductor Bar System

- Efficient: The product’s compact design makes it space-saving, easy to install, and requires minimal maintenance, contributing to an overall efficient experience.

- Reliable: The product’s stable and highly conductive design ensures consistent and dependable power delivery, enhancing its reliability.

- Secure: The product’s flexible design, coupled with its insulated construction, promotes safe operation and adaptability to various application scenarios. Besides, we also provide you with some other construction hoist safety devices.

- Durable: The aluminum alloy protection safeguards the product against corrosion, extending its lifespan and ensuring long-lasting performance.

| Specification

| Place of Origin | Chongqing, China (Mainland) |

| Product Name | Conductor Bar |

| Certificate | ISO9001 |

| Color | Customer Required |

| Application | Elevator Equipment |

| Brand Name | CPTC |

| Usage | Construction hoist |

| Type | Elevator Parts |

| Model | HFP |

| Material | Aluminum |

| Stand length | 3 Metres |

| Why Choose Us

By leveraging cutting-edge technology, CPTC designs and manufactures construction equipment that surpasses industry standards. Our focus on innovation enables us to deliver solutions that optimize project timelines and minimize costs.

Our Advantages:

Timely Deliveries

Understanding the critical nature of spare parts, CPTC prioritizes rapid order processing and delivery, minimizing equipment downtime and operational disruptions.

Rigorous Quality Control

CPTC implements a multi-stage quality control process throughout production, ensuring that every component meets the highest standards for safety, reliability, and performance.

Effortless Ordering

Place orders conveniently online or through our dedicated customer support, saving you time and effort.

Guaranteed Spare Parts Availability

Enjoy hassle-free maintenance with our year-long supply of essential spare parts.

Thorough Quality Checks

Our meticulous inspection process includes rigorous testing at various production stages, guaranteeing product reliability and durability.