Passenger and Material Hoist

- Ensure safety

- Use high-quality steel

- Simple and cost-saving

Product Description

| Main Materials of Passenger and Material Hoist

- high quality steel plate Q235B bended by special machine: Thickness 4.5mm

- Welded steel tube Q235B (seamless steel tube 20# is also available):Ø76*4.5mm or Ø89*4.5mm(Thickness of 6mm or 8mm is also available)

| The Main Structure of the Cage

- The main structure of the cage is made of high-quality steel after bending.

- bottom and roof of the Cage adopt a trapezoidal frame.

- The bottom and the roof are fully symmetry.

- The plane of symmetry is connected by a Bending plate, Bending channel, and square pipe which make it firm, straight, and balanced in use.

- The wall around the cage can be fixed by a Punched Aluminium plate, a Punched zinc plate, and steel wire mesh.

- Surface Treatment: Blasting, Baking finished, Galvanized.

- Mast section with a single rack or double rack.

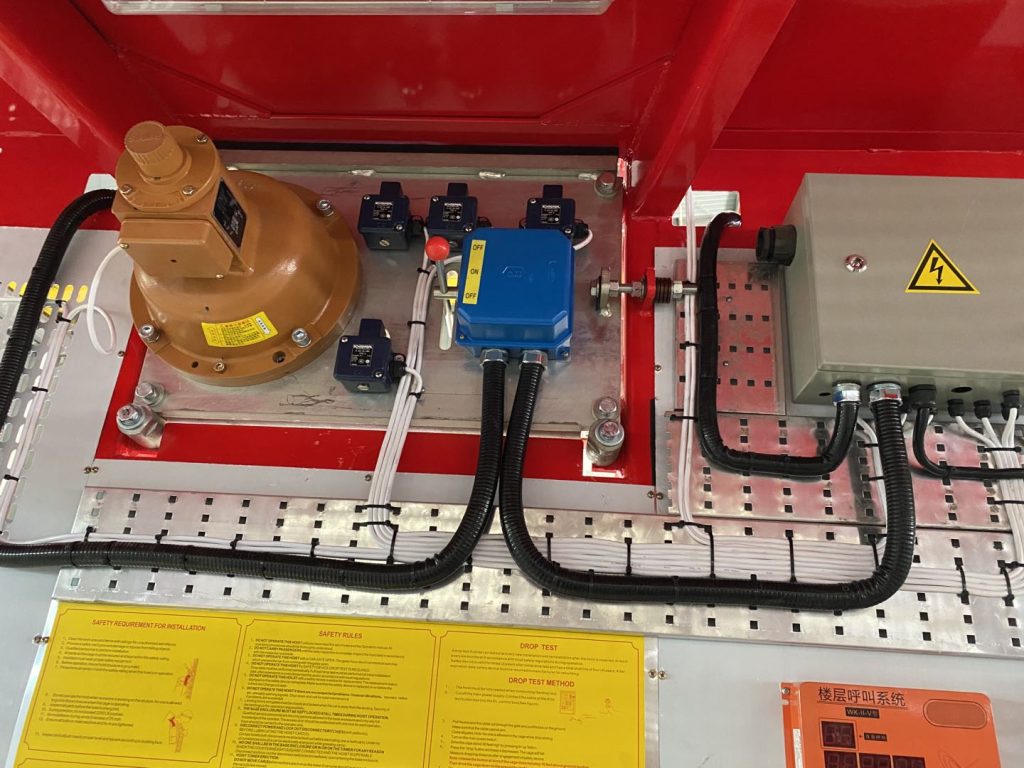

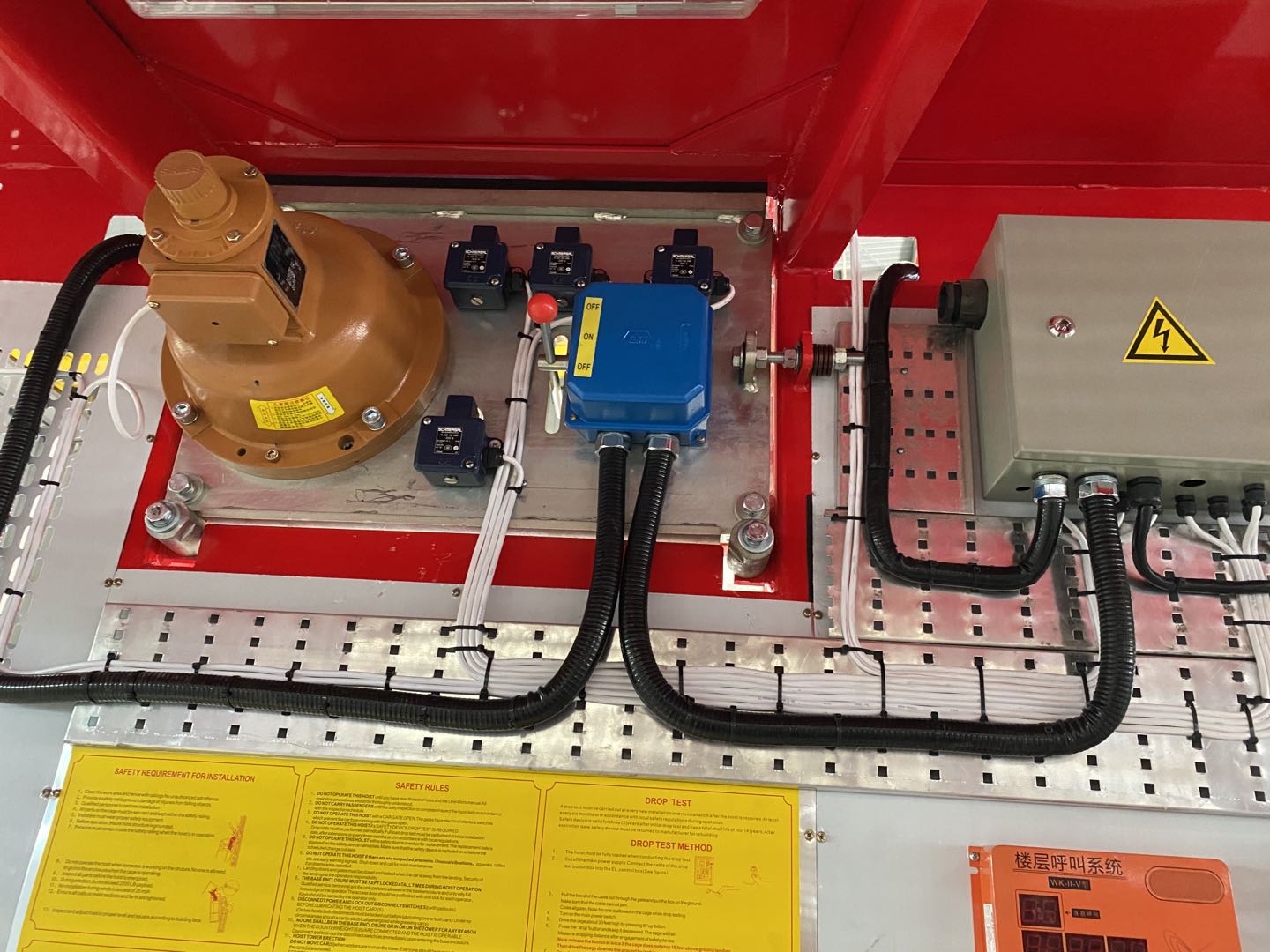

| Electrical Equipment and Spare Parts

We have the following safety devices to protect the safety of the goods and passengers. safety and life are the most important principles in our company.

- SAJ series Safety Device

- Top limit switch and Bottom limit switch

- 3-phase switch

- Buffer Spring

- Mechanical lock

- Reducing device

- Brake pieces

- Overload Protector

- Leakage Protection switch

- Emergency button

- Terminal and Final stopping switches

- Guard Rail

- Motor

- Gearbox

- Invert

| Protective Measures of Passenger and Material Hoist

- A Master switch On the operation board: When the button closes, unexpected action to other buttons can not let the cabin work.

- Anti-falling safety device (with Centrifugal breaking system ): When all other protection devices lose action, it can brake the cabin from falling.

- Mechanical interlocking door: when the cabin running it can close by itself to protect people from dropping.

- Overload calling device.

- upper and lower travel limit: They can limit the cabin go over the top mast.

- The top mast section has no rack to limit the cabin overrunning and dropping.

- Manual button: You can operate the bottom to let the cabin go down when interruption of the power supply.

- Emergency switch: When the cabin losing control and over-running, you can operate the button.

- Workshop Details and Transport Details.

- All Production Lines adopt a standard of the fixture, mould, and gauge.

- Each Construction Lift should be testing-run and adjusted in the Factory.

| Features of Construction Material Hoist

- Direct Start and Stop: Construction material hoists typically feature direct start and stop controls, allowing for precise control of the hoist’s movement.

- Simple and Cost-Effective: Compared to more complex lifting systems, construction material hoists offer a relatively simple design and operation.

- Optional Hot-Dip Galvanized Cages: This treatment makes the cages resistant to harsh weather conditions and extends their lifespan.

- Installation within Hoistway: The hoist mechanism is typically installed within the hoistway, the vertical shaft that guides the hoist’s movement.

- Modular Hoist Cages: The cages can be configured to accommodate different load capacities and heights, ensuring a flexible and efficient solution for various material handling needs.

| Specification

Technical Data of Construction Material Hoist:

| Model | Capacity (kg) | Lifting speed (m/min) | Cage size (m) |

| SC200G | 2000 | 0〜63 | 21×1.7×6.5 |

| SC270G | 2700 | 0〜63 | 22×1.4×4 |

| SC200/200G | 2×2000 | 0〜96 | 3.2×1.5×63 |

| SC270/270G | 2×2700 | 0〜96 | 3.8×1.8×61 |

Specification of SC Series General Hoist:

| Classification | Model | Capacity (kg) | Lifting speed | Motor power | Counter weight (kg) | |

| Single cage | With counter weight | SCD200 | 2000 | 36 | 2 x 11 | 1000 |

| SCD270TD | 2700 | 36 | 3 x 11 | 1000 | ||

| SCD320TD | 3200 | 36 | 3 x 11 | 1200 | ||

| No counter weight | SCD100TD | 1000 | 36 | 2 x 11 | / | |

| SC120TD | 1200 | 36 | 2 x 11 | / | ||

| SC200TD | 2000 | 36 | 3 x 11 | / | ||

| Twin cage | With counter weight | SCD200/200 | 2 x 2000 | 36 | 2x2x11 | 2×1000 |

| SCD270TD/270TD | 2 x 2700 | 36 | 2x3x11 | 2×1000 | ||

| SCD320TD/320TD | 2 x 3200 | 36 | 2x3x11 | 2×1200 | ||

| No counter weight | SCD100TD/100TD | 2 x 1000 | 36 | 2x2x11 | / | |

| SC120TD/120TD | 2 x 1200 | 36 | 2x2x11 | / | ||

| SC200TD/200TD | 2 x 2000 | 36 | 2x3x11 | / | ||

- Customization from “GJJ optional functions”in this book

- Standard cage dimension is 3.2×1.5×2.5,other available cage dimension(LxWxH)(m)

- 2.5×1.3×2.5; 3×1.3×2.5; 3.6×1.5×2.5; 3.8×1.5×2.5;4.0×1.5×2.5;4.2×1.5×2.5 special dimension can be made according to requirement of customer.

- Capacity ,lifing speed etc can be selected according to requirement of customer.

- Standard mast section is 650x650x1508mm,or can be made according to requirement of customer.

- Motor/reducer option:GJJ motor(Chinese);Nord motor special for GJJ(Germany)

- Tie-in type I apply for the height <=150m

- The hoist over 200 meters with counter weight is not recommended.

- Capacity:2000kg

- Lifting speed:0-96m/min

- Erection height: 580m.

| Why Choose Us

As a socially responsible company, CPTC prioritizes the safety and well-being of our employees, customers, and communities. We adhere to strict quality and safety standards to ensure the highest level of product reliability and workplace safety.

Our Advantages:

Premium Quality Assurance

CPTC spare parts undergo stringent quality control measures to ensure optimal performance, durability, and safety, minimizing downtime and maximizing equipment lifespan.

Building Long-Term Partnerships

CPTC aims to cultivate long-term partnerships with our clients. We are dedicated to exceeding your expectations and providing ongoing support throughout your projects.

Competitive Pricing

We are committed to providing high-quality products at competitive prices, ensuring you get the best value for your investment.

All-Inclusive Solutions

From product selection to installation, our comprehensive service covers every aspect of your project.

Invest in Your Equipment with Our After-Sales Care

Protect your investment with our value-added services: expert installation, reliable spare parts, and ongoing technical support.