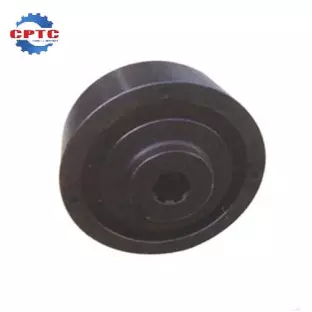

Coupling

- Various models available

- Wide range of applications

- Gear structure, welded connection method

- Easy installation and disassembly

Product Description

Couplings are commonly used connecting devices in mechanical transmissions, used to connect the driving shafts and driven shafts of different mechanisms, so that they rotate together and transmit motion and torque. CPTC has standardized the production and manufacturing of couplings, and its products are widely used in CNC machine tools, CNC lathes, machining centers, engraving machines, CNC milling machines, computer gongs, metallurgical machinery, mining machinery, petroleum machinery, chemical machinery, lifting machinery, transportation machinery, light industry machinery, textile machinery, pumps, fans and other fields.

| Features of Coupling

- Intermediate elastomer connection;

- It can absorb vibration, compensate radial, angular and axial deviation;

- Oil resistance and electrical insulation;

- Clockwise and counterclockwise rotation characteristics are identical.

- Fix the positioning screw.

| Specification of Coupling

| Model NO. | Many kinds |

| Structure | Gear |

| Material | Carbon Steel |

| Warranty | 1years |

| Construction Hoist Spare Parts | Rubber Coupling |

| Coupling and Rubber for | Gjj Baoda Construction Hoist |

| Transport Package | Wooden Case |

| Connection | Welding |

| Flexible or Rigid | Flexible |

| Standard | Standard |

| Color | Black, Yellow |

| Location | china |

| HS Code | 8483600090 |

| Application of Coupling

Couplings have a wide range of applications and are suitable for the following industries and applications:

- Machine tool manufacturing: Couplings are widely used in the machine tool manufacturing industry to achieve high-speed rotation and precision control of machine tools.

- Aerospace industry: Couplings are used in aircraft engines and flight control systems to ensure the safe operation of machinery.

- Petrochemical industry: Couplings are widely used in fields such as oil drilling, where they can transmit high torque and high speed while minimizing transmission errors.

- Light industries such as papermaking and textiles: Couplings are used in various types of longitudinal and transverse linkage equipment, such as spinning machines, screen printing machines, and winding machines.

| Installation and Removal

- Clean the dust on the surface of the installation shaft, and apply a thin layer of lubricant oil;

- Clean the inner hole of coupling and apply lubricant oil;

- Insert the coupling into the installation shaft; if the hole diameter is tight, take care not to hit the installation with a hammer or hard metal;

- After the positioning is completed, first tighten the screws slightly in the diagonal direction with the torque wrench (specified tightening torque 1 / 4);

- Increase the force (1 / 2 of the specified tightening torque) and repeat step 4;

- Tighten and fix according to the specified tightening torque;

- Finally, tighten the set screws in the circumferential direction

- When disassembling, please carry out under the condition that the device stops completely; loosen the locking screws in turn.

| Why Choose Us

As a customer-focused organization, CPTC offers a complete one-stop solution for construction projects. From product selection and procurement to installation and after-sales service, we provide comprehensive support throughout the project lifecycle. Our advantages are the following:

Trustworthy Performance

Backed by a fifteen-year reputation for excellence, CPTC spare parts deliver consistent and reliable performance, enhancing the overall efficiency of your operations.

Extensive Network

CPTC has established a strong network of reliable suppliers and distributors worldwide, guaranteeing you access to a wide range of crane parts and prompt service.

Customer-Centric Quality

Our rigorous quality control measures are driven by a steadfast commitment to delivering products that exceed customer expectations.

Peace of Mind

Rely on our one-stop service for hassle-free procurement, ensuring all your construction needs are met in one place.

Maximize Equipment Uptime with Comprehensive Support

Our after-sales package is designed to minimize downtime and optimize equipment performance.