Tower cranes are indispensable tools in the construction industry, but their operation in windy conditions poses significant safety risks. This article provides comprehensive guidelines for safe tower crane construction and operation in windy weather. We will delve into factors affecting tower crane stability in high winds, safety management strategies, and the critical role of anemometers in ensuring safe operations.

We can watch a video where the construction manager explains to the crane operator the dangers of operating a tower crane in strong winds.

What Wind Speed Can a Tower Crane Withstand?

Windy weather is a common occurrence, and many construction sites continue to operate tower cranes even in strong winds. This not only puts operators at risk but also increases the likelihood of serious crane accidents.

According to standardized foundation specifications for tower cranes, operation is generally permitted in winds up to force 4 on the Beaufort scale. However, if the crane is not in active use, it should be parked facing the wind to minimize the impact of wind forces on the counterweight. For wind speeds exceeding force 6, crane operations should be halted entirely to prevent accidents involving the counterweight.

Safety Management for Construction in Windy Weather

Effective safety management is crucial for mitigating risks associated with tower crane operations in windy conditions. Key considerations include:

- When wind speed reaches force 6 or above, scaffolding erection and dismantling shall be stopped, outdoor formwork removal and installation at heights shall be suspended, and all outdoor hoisting operations shall be ceased. Elevators must be stopped, cages lowered to the ground floor, and power cut off.

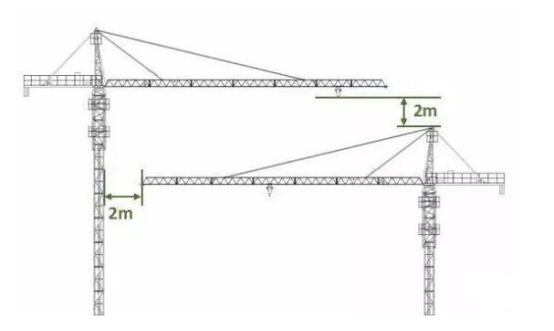

- Tower crane elevating or lowering operations shall not be carried out when wind speed reaches force 4 or above. If wind speed suddenly increases to force 4 during operation, it must be stopped immediately, and all connection bolts on the upper and lower tower sections shall be tightened.

- If wind speed reaches force 6 or above during operation, tower crane operation shall be stopped immediately, the rail clamp shall be locked, the brake of the slewing mechanism shall be 1 fully released, and the boom shall be allowed to rotate with the wind.

- Piling operations shall be stopped in winds of force 6 or above. When wind speed exceeds force 7, the pile driver shall be parked facing the wind, and guy ropes shall be added or the piles laid flat on the ground.

- After strong winds of force 6 or above, the foundation pit and safety facilities shall be inspected promptly.

- After a typhoon, safety facilities at heights shall be inspected one by one. If any loosening, deformation, damage, or detachment is found, it shall be repaired immediately.

- After strong winds of force 6 and heavy rain, scaffolding and other foundations shall be inspected and accepted.

- Suspended scaffolds shall not be raised or lowered in force 5 or above winds. After winds of force 6 or above, the scaffolding shall be inspected and accepted before resuming work.

- When wind speed reaches force 5 or above, suspended platform work shall be stopped, and the platform shall be lowered to the ground. Steel ropes and cables shall be tied and secured.

- Material hoists must stop operating in strong winds with a speed of 13 m/s or above.

Tower Crane Safety Operation Guide in Windy Weather

Tower cranes play a pivotal role, especially in structural construction. By strengthening the command, management, and coordination of tower crane operations, we can ensure the safe, efficient, and optimal utilization of tower cranes during construction, thus meeting the demands of production schedules.

Tower Crane Safety Requirements

- Grounding Protection: Tower cranes must be effectively grounded to prevent lightning strikes. A minimum of 10mm² multi-strand copper wire should be used for the grounding connection, and the ground resistance should not exceed 4 ohms.

- Verticality: Upon completion of installation and without load, the vertical deviation of the tower from the ground shall not exceed 3/1000.

- Bolting and Adjustments: All connection bolts and pins on the tower crane should be tightened to the specified torque. The settings of the hydraulic system, safety valves, electrical system protection devices, and other mechanical components must comply with the requirements.

- Torque Limiter: The combined error of the torque limiter shall not exceed 8% of its rated value. When the load exceeds the rated value, the torque limiter shall cut off the power supply to the hoisting and luffing motions. The mechanism can still perform lowering and luffing-out motions.

- Height Limit Switch: When the hook frame is lifted to a height of at least 1 meter from the fixed sheave, the height limit switch shall cut off the power supply to the hoisting motion.

- Luffing Limit Switch: When the trolley reaches 0.5 meters from the end of the boom, the luffing limit switch shall cut off the power supply to the trolley motion.

- Load Testing: After installation and inspection, the tower crane must undergo no-load, static load, and dynamic load tests. The static load test shall be conducted at 125% of the rated load, and the dynamic load test shall be conducted at 110% of the rated load. The crane can be put into use only after passing these tests.

Important Considerations

1. Strictly Prohibit Overloading

Overloading a tower crane is strictly prohibited.

Although tower cranes are designed with a certain level of theoretical overload capacity to accommodate practical construction requirements, exceeding the rated load for a given working radius can lead to tipping. When the overturning moment of the load exceeds the stabilizing moment, the crane becomes unstable and may collapse.

- Avoid Inclined Lifting

Before lifting a load, ensure that the weight does not exceed the crane’s rated capacity. Establish a vertical lifting path and avoid inclined lifting, especially in winds of force 6 or above.

Inclined lifting increases the overturning moment of the load, generating horizontal and vertical components at the lifting point. This creates an additional overturning moment at the crane’s base support, reducing the stability factor and increasing the risk of tipping.

- Ensure a Level and Solid Foundation for the Crane

When erecting a tower crane, select a firm and level ground with sufficient bearing capacity, and pay attention to reinforcement.

As tower cranes must support both their own weight and the weight of the lifted load, uneven or weak foundations are a significant cause of tipping accidents. If the foundation is uneven, excessive vertical misalignment can increase the overturning moment and reduce the crane’s stability.

Additionally, erecting a crane on soft or loose soil can lead to soil settlement and crane tipping, as the ground may not be able to support the load.

Anemometers: Technology Safeguarding High-altitude Work Safety

Anemometers play a vital role in ensuring tower crane safety. By continuously monitoring wind speed, they enable operators to make informed decisions about when to continue or halt operations. Key benefits of using anemometers include:

- Real-time data: Provides accurate and up-to-date wind speed information.

- Early warning: Enables early detection of high-wind conditions.

- Improved decision-making: Supports data-driven decisions regarding crane operations.

Final Words

Safe tower crane operation in windy weather requires a combination of engineering knowledge, effective safety management, and the use of advanced technology. By following the guidelines outlined in this article and investing in equipment like anemometers, construction companies can significantly reduce the risk of accidents and ensure the safety of their workers.

Related Products

Brake Disc for Tower Crane Motor

Rapid Reaction

High Durability

High Quality Crane Operator Cabin for Tower Crane

High quality steel material for frame

The cab is…

Tower Crane Trolley Device

Multiple functions

Intuitive operation