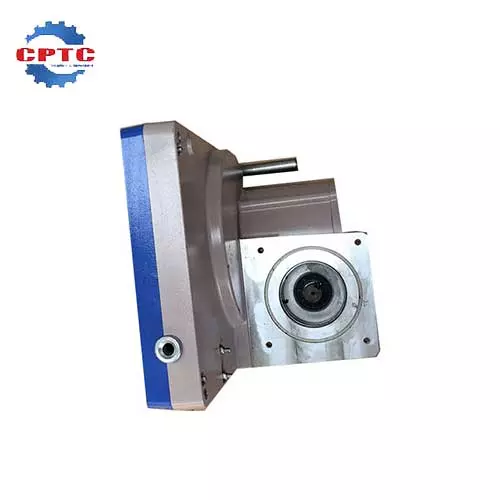

Hoist Gearbox

- Economically Efficient

- Stable and reliable operation, secure

- High flexibility, adjustable speed

- Wide range of applications

Product Description

Electric cradle hoists are indispensable equipment for high-rise construction, widely used in various fields such as building, renovation, and maintenance. Powered by an electric motor, the winch rotates, raising the cradle to the desired height via steel wire ropes. These hoists offer a range of advantages, including efficiency, safety, and flexibility.

Utilizing CPTC’s electric cradle hoists will further enhance work efficiency and safety, bringing greater convenience to the construction industry.

| Features of Hoist Gearbox

- Enhanced Efficiency: Electric suspended platform hoists can quickly and efficiently transport construction personnel and materials to high-altitude work sites, significantly improving work efficiency.

- Reduced Labor Intensity: Traditional scaffolding requires manual assembly and disassembly, which is labor-intensive and time-consuming. In contrast, electric suspended platform hoists are easy to operate, reducing the labor burden on workers.

- Improved Safety: Electric suspended platform hoists are equipped with brakes and safety devices to ensure the safety of construction personnel. Additionally, guardrails and safety doors are installed on the edges of the platform to prevent accidental falls.

- Strong Flexibility: Electric suspended platform hoists can be adjusted in height and position according to construction needs, making them suitable for various high-altitude work environments.

- Economic and Practical: While the initial investment cost of electric suspended platform hoists is relatively high, they have a long service life and low maintenance costs, saving labor and time expenses.

| Specification

| Model | ZLP630 | ZLP800 | |

| Suspended Platform | Rated Load | 630KG | 800KG |

| 1m,2m,3m,1.5m,2.5m | Rated Lifting Speed | 9.3±0.5m/min | 8.2±0.5m/min |

| to the length made. | Length of Platform | 6000mm | 7500mm |

| In any Combination | Surface Proceeding | Aluminum;steel materials(Galvanized,Spraying) | |

| Lifting Height | 100m | 100m | |

| Cable | 100m | 100m | |

| Max Lifting Height | 200m | 200m | |

| Steel Rope | 8.3mm | 9.1mm | |

| Hoist | Power | 1.5KW*2 | 1.8KW*2 |

| Voltage | 380V, 50HZ, Three-Phase(standard) | ||

| Safety Lock | Permission Force of Impact | 30KN | 30KN |

| Locking Cable Angle | 3°~ 8° | 3°~ 8° | |

| Suspension Mechanism | Front Beam Overhang | 1.3 ~ 1.5m ±0.26 | 1.3 ~ 1.5m ±0.26 |

| Support Adjustable Height | 1.44 ~ 2.14m ±0.26 | 1.44 ~ 2.14m ±0.26 | |

| Counter Weight | 1000KG | 1000KG | |

| 20′ GP Container | 9sets | 8sets | |

| 40′ GP Container | 12sets | 12sets | |

| 40’HQ Container | 27sets(without couter weight) | ||

| Why Choose Us

By leveraging cutting-edge technology, CPTC designs and manufactures construction equipment that surpasses industry standards. Our focus on innovation enables us to deliver solutions that optimize project timelines and minimize costs.

Our Advantages:

Timely Deliveries

Understanding the critical nature of spare parts, CPTC prioritizes rapid order processing and delivery, minimizing equipment downtime and operational disruptions.

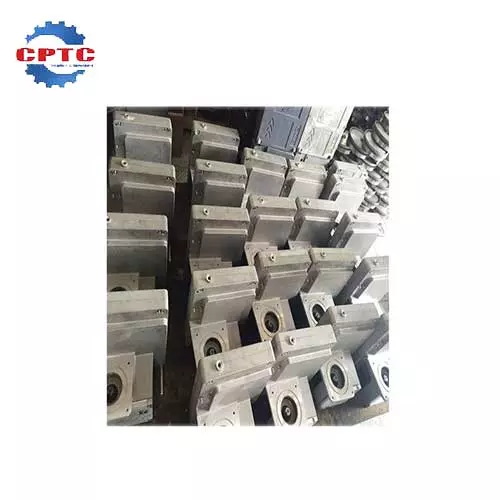

Rigorous Quality Control

CPTC implements a multi-stage quality control process throughout production, ensuring that every component meets the highest standards for safety, reliability, and performance.

Effortless Ordering

Place orders conveniently online or through our dedicated customer support, saving you time and effort.

Guaranteed Spare Parts Availability

Enjoy hassle-free maintenance with our year-long supply of essential spare parts.

Thorough Quality Checks

Our meticulous inspection process includes rigorous testing at various production stages, guaranteeing product reliability and durability.