Suspended platforms, such as like elevators and lifts, are essential components of modern infrastructure. However, their operation involves inherent risks, particularly in the event of power failures or mechanical malfunctions. To mitigate these risks and ensure the safety of passengers, electromagnetic brake coils play a crucial role. These devices harness the power of electromagnetism to provide reliable and efficient braking, safeguarding lives and property.

In this article, we will delve into the workings of electromagnetic brake coils, explore their significance in suspended platforms, and discuss the signs of a failing coil and the necessary actions to take.

How Does an Electromagnetic Brake Coil Work?

There is a detailed work introduction for the electromagnetic brake coil as one of the suspended platform parts:

- Power Supply: When the platform is operational, a direct current (DC) power supply provides electrical energy to the brake coil. This continuous flow of electricity is essential for maintaining the brake’s functionality.

- Magnetic Field Generation: As the DC current passes through the coil, it generates a magnetic field around the coil. This magnetic field is a region of space where magnetic forces can be detected. The strength of the magnetic field is directly proportional to the amount of current flowing through the coil.

- Brake Activation: The generated magnetic field interacts with a ferromagnetic component (a material that can be magnetized, such as iron or steel) located within the brake mechanism. The magnetic attraction between the coil’s magnetic field and the ferromagnetic component causes the brake mechanism to release. This allows the platform to move freely.

- Power Failure: In the event of a power failure, the DC current to the coil is interrupted. As a result, the magnetic field collapses, weakening the magnetic attraction between the coil and the ferromagnetic component. This allows the brake mechanism to engage and stop the platform, preventing it from moving unintentionally.

Why Is an Electromagnetic Brake Coil Important for Suspended Platforms?

- Enhanced Safety: An electromagnetic brake coil is a crucial safety component that significantly reduces the risk of accidents. It acts as a failsafe mechanism, preventing the platform from moving unintentionally, particularly in situations like power outages or mechanical failures. If the power supply is interrupted, the magnetic field collapses, and the brake automatically engages, bringing the platform to a safe stop.

- Reliable Braking Performance: Electromagnetic brakes offer reliable and consistent braking performance. The magnetic force generated by the coil ensures that the brake engages promptly and firmly, regardless of external factors such as temperature fluctuations or wear and tear. This reliability is essential for maintaining the safety and integrity of the suspended platform.

- Efficient Emergency Stops: In emergency situations, a rapid and effective braking system is paramount. Electromagnetic brakes provide a quick and efficient way to halt the platform’s movement. By simply interrupting the power supply, the brake can be activated instantly, minimizing the risk of accidents and injuries.

What Are the Signs of a Failing Brake Coil and What Should I Do?

Signs of a Failing Brake Coil

A failing electromagnetic brake coil can exhibit several warning signs that indicate potential issues:

- Delayed Braking: The platform takes significantly longer than usual to come to a complete stop after the power is cut off. This can be a result of a weakened magnetic field, which may be caused by a damaged coil or insufficient power supply.

- Inconsistent Braking: The braking force may fluctuate, leading to unpredictable stopping behavior. This can be attributed to variations in the power supply, a malfunctioning coil, or issues with the brake mechanism.

- Noise or Vibration: Unusual sounds or vibrations emanating from the brake area can signal a problem with the coil or its components. These noises could indicate excessive wear, misalignment, or a loose connection within the brake system.

- Visible Damage: Physical damage to the coil, such as cracks, burns, or discoloration, is a clear indication of a failing component. This type of damage can be caused by overheating, electrical faults, or mechanical stress.

What to Do if You Suspect a Failing Brake Coil

If you notice any of these signs, it’s crucial to take immediate action to prevent accidents and ensure the safety of the platform and its occupants. Here’s what you should do:

- Stop Using the Platform: Immediately cease operation of the platform to avoid potential hazards.

- Consult a Qualified Technician: Seek the expertise of a qualified technician or engineer specializing in elevator or platform systems. They can accurately diagnose the problem and recommend appropriate solutions.

- Schedule Inspection and Maintenance: Arrange for a thorough inspection of the brake coil and the entire braking system. Regular maintenance, including cleaning, lubrication, and adjustment, can help prevent future failures.

- Replace the Coil if Necessary: If the coil is found to be damaged or defective, it should be replaced with an original or compatible replacement part. Ensure that the replacement is performed by a qualified technician to guarantee proper installation and functionality.

Brakes for Safety

Electromagnetic brake coils are indispensable safety features in suspended platforms. By understanding their operation, recognizing the signs of failure, and implementing proper maintenance practices, we can significantly enhance the safety and reliability of these systems. Regular inspections, timely repairs, and adherence to professional manufacturer‘s guidelines are essential to ensure the continued effectiveness of electromagnetic brake coils. By prioritizing safety and investing in preventive maintenance, we can safeguard lives and protect property, making suspended platforms a safe and efficient mode of transportation.

Related Products

Construction Hoist Floor Calling System

Effortless installation

Reliable performance over extended ranges

Accommodates…

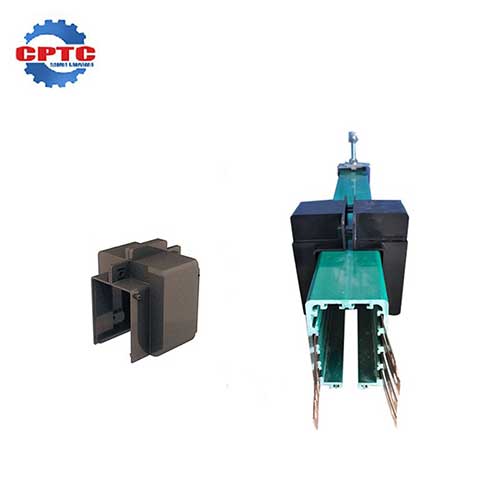

Conductor Bar System

Stability and high…