Safety ropes are an indispensable tool in the construction industry, providing a critical lifeline for workers performing tasks at elevated heights. Proper knot-tying techniques are essential to ensure the effectiveness and safety of these ropes. This article will delve into the necessity of using safety ropes in construction, explore common knotting techniques, and discuss precautions for their safe use.

The Necessity of Using Safety Ropes in Construction

Construction work inherently involves risks, particularly when tasks are performed at elevated heights. Falls are a leading cause of injuries and fatalities in the industry. Safety ropes serve as a crucial safety measure, preventing workers from plummeting to the ground in the event of a slip or trip.

· Ensuring worker safety: Both safety ropes and safety harnesses are designed to protect workers during high-altitude operations. Safety ropes withstand high tensile forces to prevent workers from falling or losing their footing, ensuring their safety during elevated work. Safety harnesses, on the other hand, connect the worker to a fixed point, preventing them from losing balance or falling and thus safeguarding their well-being.

· Improving work efficiency: In high-altitude operations, safety ropes and harnesses can stabilize the body, preventing swaying and falling, thereby improving work efficiency. With a safety harness, workers can complete tasks more quickly, reducing unnecessary breaks and enhancing overall productivity. In prolonged high-altitude operations, safety ropes can also reduce worker fatigue, making the work more comfortable.

· Preventing accidents: High-altitude work is inherently risky, and accidents can easily occur without proper safety measures. The use of safety ropes and harnesses effectively prevents accidents during high-altitude operations, protecting workers’ safety. In emergency situations, safety ropes and harnesses can effectively absorb impact forces, safeguarding workers’ lives and physical health.

Common Safety Rope Knotting Techniques

A variety of knotting techniques are employed in the construction industry to ensure the safe and effective use of safety ropes. These knots play a crucial role in securing workers to anchor points, creating loops for attaching harnesses, and forming reliable systems for fall protection.

Here are some of the most essential safety rope knots commonly used in construction:

1. Half Hitch and Double Fisherman’s Knot

- Characteristics: The best choice for connecting two ropes; easy to untie after bearing weight.

- Usage: Connecting main and auxiliary ropes, connecting two safety harnesses, etc.

- How to tie: First, tie a half hitch on one rope, then pass the other rope through the half hitch and tie a double fisherman’s knot to secure it.

2. Double Fisherman’s Knot

- Characteristics: Ideal for connecting loops or ropes that won’t be untied frequently; difficult to untie after bearing weight.

- Usage: Connecting safety harnesses, fixing anchor points, etc.

- How to tie: Cross the two ropes over each other, then wrap each rope around the other twice and tie a knot.

3. Double Clove Hitch

- Characteristics: Easy to adjust, suitable for setting up fixed points.

- Usage: Fixing ropes, building anchor points, etc.

- How to tie: Tie two clove hitches on the rope and loop them around the fixed object.

4. Prusik Knot

- Characteristics: Can slide along the rope, used for ascending and descending.

- Usage: Self-rescue, rescue, securing loads, etc.

- How to tie: Wrap the rope around itself twice, then pass the rope end through the two loops and pull tight.

5. Italian Hitch

- Characteristics: Easy to operate, often used for belaying.

- Usage: Protecting climbers, rescue, etc.

- How to tie: Pass the rope through the carabiner, wrap it around the carabiner once, and then tie a half hitch.

6. Water Knot

- Characteristics: Strong and durable, difficult to untie.

- Usage: Fixing the end of a rope, making a rope loop, etc.

- How to tie: Tie a complex loop on the rope.

7. Prusik Knot

- Characteristics: Can slide along the rope, used for ascending and descending.

- Usage: Self-rescue, rescue, securing loads, etc.

- How to tie: Same as the Prusik knot.

8. Figure-Eight Follow-Through

- Characteristics: Safe and reliable, commonly used as a safety knot.

- Usage: Connecting safety harnesses, fixing anchor points, etc.

- How to tie: Tie a figure-eight on the rope and pass the rope end through the figure-eight.

Precautions for Using Safety Ropes

To ensure the safe and effective use of safety ropes, it is essential to follow these precautions:

· Regular Rope Inspection: Inspect ropes for signs of wear, damage, or fraying. Replace any damaged ropes and strictly prohibit the use of non-standard or damaged safety ropes.

· Worker Training: Provide comprehensive training to workers on the correct use and maintenance of safety ropes, including knotting techniques and emergency procedures. When working at heights, workers must wear approved safety harnesses and safety ropes.

· Follow Manufacturer’s Instructions: Adhere to the manufacturer’s guidelines for the specific ropes and equipment being used. The use of hemp rope as a safety rope is strictly prohibited.

· Use Shock Absorbers: If the safety rope exceeds three meters in length, a shock absorber must be installed to ensure the safety of workers at height.

· One Rope, One Person: Two people cannot use one safety rope simultaneously. During high-risk operations, to ensure the safety of workers during movement, they should be attached to a safety rope while wearing a safety harness.

Final Thoughts

The use of safety ropes is a fundamental aspect of construction safety. By understanding the importance of proper rope selection, knotting techniques, and inspection procedures, workers can significantly reduce the risk of falls and injuries. It is essential for all construction professionals to prioritize safety and to ensure that all workers are equipped with the knowledge and tools necessary to work safely at heights.

Related Products

Electromagnetic Brake Coil

Electromagnetic Brake Coil

High-speed, high-precision control

Quick-acting, precise control

Safety Rope

Lightweight and Portable

Durable and Long-lasting

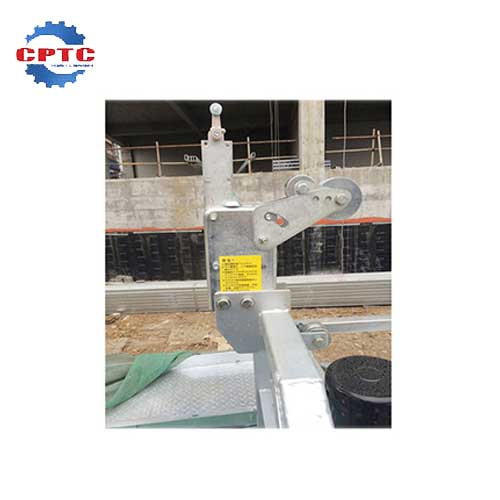

Limit Switch

Compact and Lightweight

Easy Installation

Suspended Platform Safety Lock

Easy to Operate and Use

Made…