Tower cranes play a vital role in modern construction projects, providing the ability to lift and transport heavy materials efficiently. One of the key components of a tower crane is the , which allows the crane to move loads horizontally along the jib. This movement is crucial for optimizing workflow, enhancing efficiency, and ensuring construction projects meet deadlines.

In this article, we will explore the tower crane trolley system, including its definition, working principles, types, maintenance tips, andselection criteria.

What is a Tower Crane Trolley?

A tower crane trolley is a mechanism that enables the movement of the load-carrying hook along the horizontal arm (jib) of a tower crane. This system enhances the flexibility of the crane by allowing it to transport materials across a wide area without repositioning the entire crane structure.

The trolley consists of several key components:

- Trolley Frame: Supports the overall structure and guides movement.

- Wheel Assembly: Allows smooth movement along the jib.

- Drive Mechanism: Provides power for motion, usually powered by electric motors.

- Braking System: Ensures controlled and safe operations.

Key Functions of a Tower Crane Trolley:

- Horizontal Load Movement: Transports materials up to 20 tons laterally.

- Micro-Adjustment: Enables millimeter-level positioning using servo-controlled brakes.

- Safety Integration: Automatically locks loads during wind speeds exceeding 13 m/s.

Tower crane trolleys are essential for high-rise buildings, bridges, and infrastructure projects that require precise load handling over a large working radius.

How Does a Tower Crane Trolley Work?

The tower crane trolley mechanism operates using a combination of motors, cables, pulleys, and control systems. Here’s how it works:

- Motorized Drive System: An electric motor powers the trolley, moving it along the jib through a rail or track system.

- Wire Rope and Pulley System: The lifting hook is connected to a wire rope that moves in sync with the trolley to position the load accurately.

- Control Mechanism: Operators control the trolley’s movement using a control panel or remote system to ensure smooth operation.

- Braking and Safety Features: Emergency brakes and load sensors help prevent accidents and maintain stability.

Types of Tower Crane Trolleys

Tower crane trolleys are not a one-size-fits-all solution. Different construction projects have varying requirements in terms of lifting capacity, reach, speed, and site constraints. Consequently, several types of trolley systems have been developed to cater to these diverse needs. The primary distinctions lie in their trolley movement mechanism and drive systems.

Fixed Trolley vs. Luffing Trolley

| Feature | Fixed Trolley | Luffing Trolley |

| Jib Angle | Horizontal | Adjustable (30°-85°) |

| Best For | Open sites | Congested urban areas |

Single Drive vs. Dual Drive System

- Single Drive Trolley Systems: These systems utilize a single motor and gearbox to drive the trolley along the jib. While simpler in design and potentially more cost-effective, single drive systems may be subject to increased wear and tear on the drive components, especially for heavy loads and long jibs.

- Dual Drive Trolley Systems: Employing two independent motors and gearboxes, one on each side of the trolley, dual drive systems offer enhanced stability, smoother movement, and increased reliability, particularly for cranes with longer jibs and higher lifting capacities. The synchronized operation of the two drives ensures even distribution of forces and reduces the risk of trolley skewing or jamming.

Maintenance and Optimization Tips

Regular maintenance ensures optimal performance and extends the lifespan of a tower crane trolley mechanism. Here are essential maintenance tips:

- Regular Inspection: Conduct daily, weekly, and monthly checks as per the manufacturer’s recommendations, focusing on the condition of wheels, tracks, ropes, connections, and electrical components.

- Proper Lubrication: Adhere to the recommended lubrication schedule for all moving parts, using the specified lubricants to minimize wear and corrosion.

- Track Alignment: Ensure the trolley tracks on the jib are properly aligned and free from obstructions or damage. Misalignment can cause excessive wear on the trolley wheels and lead to operational issues.

- Rope Maintenance: Regularly inspect the trolley ropes for fraying, kinking, or damage. Ensure proper tension and lubrication.

- Drive System Checks: Monitor the performance of the trolley motor, gearbox, and VFD. Address any unusual noises or vibrations promptly.

- Encoder Calibration: Periodically check and calibrate the trolley position encoders to ensure accurate load placement.

- Operator Training: Ensure that crane operators are properly trained on the correct operation and basic maintenance procedures for the trolley system.

- Load Management: Avoid overloading the crane and ensure that loads are properly balanced to minimize stress on the trolley and jib.

Implementing a proactive maintenance program can significantly extend the lifespan of the trolley system, reduce downtime, and enhance overall safety on the construction site.

Key Factors When Selecting a Tower Crane Trolley System

When choosing a tower crane trolley, consider the following factors:

- Load Capacity: Ensure the trolley can handle the maximum weight required for the project.

- Speed and Efficiency: Evaluate the trolley’s movement speed and operational efficiency.

- Durability: Choose materials resistant to weather conditions and heavy-duty use.

- Automation Features: Advanced trolleys with smart control systems improve accuracy and reduce labor costs.

- Safety Features: Look for overload protection, emergency braking, and real-time monitoring capabilities.

Why Choose CPTC Trolley Solutions?

CPTC offers high-quality tower crane trolley systems designed for reliability, durability, and superior performance. Here’s why CPTC is the preferred choice:

- Innovative Engineering: Cutting-edge technology ensures precision and efficiency.

- High Load Capacity: Designed to handle heavy construction loads with stability.

- Customizable Solutions: Options tailored to meet specific construction project needs.

- Strict Safety Compliance: Adheres to global safety standards, reducing operational risks.

- Excellent After-Sales Support: Dedicated customer service and maintenance solutions.

With CPTC Trolley Solutions, construction companies can benefit from advanced technology, high reliability, and excellent service. Contact us today to learn more about our tower crane trolley mechanisms and how they can enhance your construction projects!

Related Products

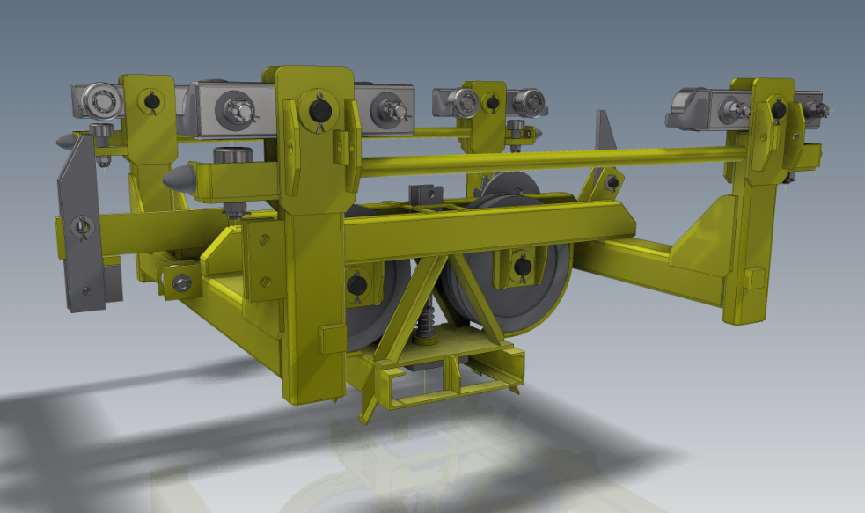

Tower Crane Trolley Device

Multiple functions

Intuitive operation

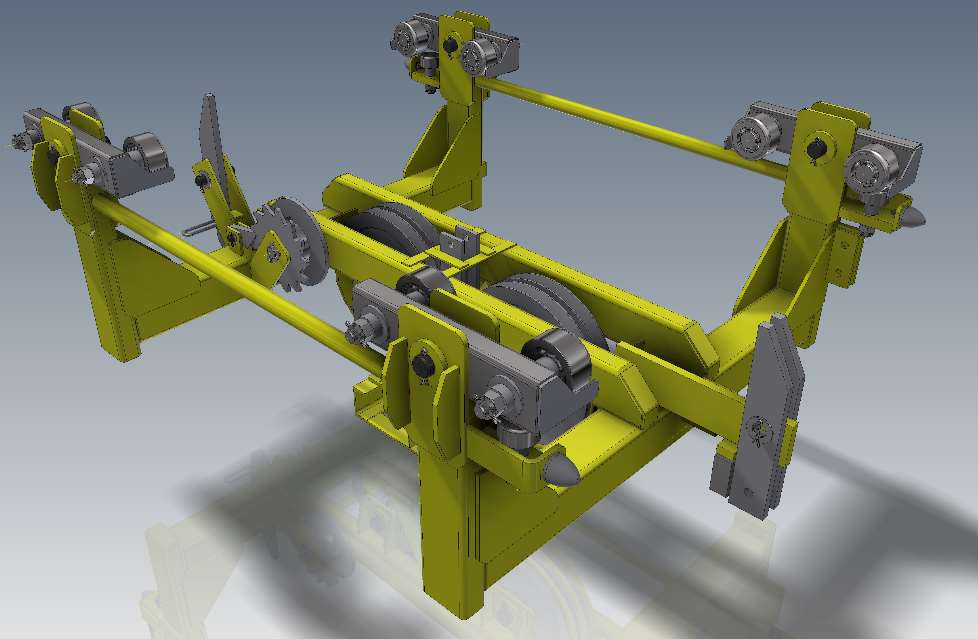

Tower Crane Trolley Chassis

Withstands heavy loads and forces

Works with supporting…

Tower Crane Trolleying Limit Gear

Controls luffing motion

Improves safety and efficiency

Enables dynamic boom…