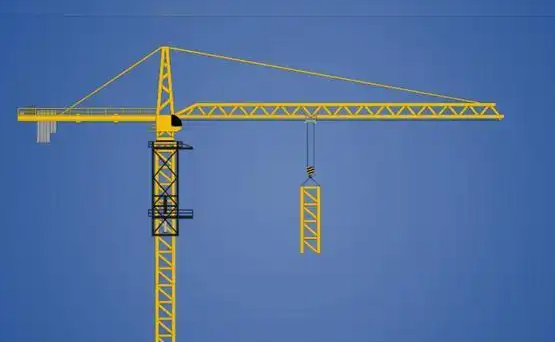

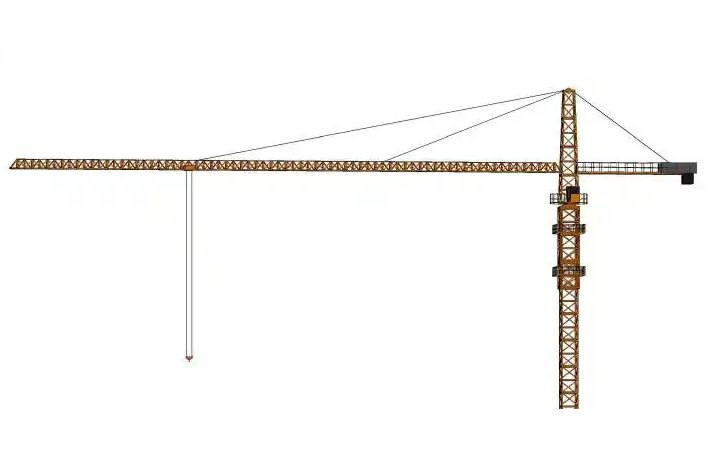

Have you ever wondered how those towering giants on construction sites are put together? Tower cranes are essential pieces of equipment in the modern construction industry, playing a crucial role in lifting heavy materials to great heights. To understand the complexity and precision involved in building these structures, let’s look into the assembly process of tower cranes and their various components.

What Are the Tower Crane Parts?

| Part | Components | Function |

| Tower | Standard sections | Provide the main vertical structure of the crane. |

| Connecting sleeves | Connect the standard sections to form the tower. | |

| Base frame | Provides a stable foundation for the tower. | |

| Boom | Main boom | The horizontal member that supports the load. |

| Luffing jib | A shorter boom that counterbalances the main boom. | |

| Luffing mechanism | Allows the boom to change its angle. | |

| Trolley | Moves along the boom to position the load. | |

| Counterweight | Counterweight blocks | Provide balance for the crane. |

| Counterweight frame | Supports the counterweight blocks. | |

| Slewing unit | Slewing ring | Allows the crane to rotate. |

| Slewing drive | Provides the power for rotation. | |

| Slewing gear | Transmits power from the drive to the slewing ring. | |

| Hoisting unit | Hoist drum | Winds and unwinds the hoist rope. |

| Hoist motor | Provides the power for hoisting. | |

| Hoist rope | Lifts and lowers the load. | |

| Sheaves | Guide the hoist rope. |

Pre-Assembly Preparation and Its Relation to Tower Crane Parts

Site Survey

The dimensions and level of the site significantly impact the placement and arrangement of the tower crane parts. Factors such as the ground-bearing capacity, proximity to obstacles, and accessibility must be considered to ensure a safe and efficient assembly process. The size of the site will determine the maximum reach of the crane, while the level of the ground will affect the stability of the base and the overall operation of the crane.

Transportation and Inspection of Components

We recommend you choose the original tower crane parts, one part of you reduces potential defects. During transportation, protective measures should be implemented to safeguard the components from impacts, vibrations, and environmental factors such as moisture and corrosion. These measures may include using appropriate packaging materials, securing the parts of the vehicle, and avoiding overloading.

Upon arrival at the site, a rigorous inspection of all components of a tower crane. The inspection should focus on:

- Tower sections: Checking for cracks, dents, or distortions in the steel members.

- Connecting elements: Ensuring that bolts, nuts, and pins are undamaged and that threaded connections are clean and free of debris.

- Boom sections: Verifying the integrity of the welds and the condition of the wear pads.

- Hoisting mechanisms: Inspecting the ropes, sheaves, and drums for wear, damage, or corrosion.

- Electrical components: Testing the functionality of all electrical systems and control devices.

Tower Crane Assembly Steps

There is a video that details the steps for installing a tower crane. If you are not comfortable watching the video right now, you can skip this part. There is also a concise text description for you.

Step 1: Installation of the Embedded Part

This initial step involves setting the foundation for the tower crane. An embedded part, often a concrete base or a steel anchorage, is securely fixed into the ground. This serves as the primary anchor for the entire crane structure, ensuring its stability and preventing it from toppling over during operation.

Step 2: Increasing Height

Once the foundation is in place, the height of the tower is gradually increased by adding prefabricated tower sections. These sections are typically bolted or pinned together to form the vertical structure of the crane. As the height increases, additional bracing and guy wires may be required to maintain the tower’s stability.

Step 3: Installation of Lifting Body

The lifting body, which houses the hoisting mechanism and controls, is installed on top of the tower. This component is responsible for lifting and lowering loads. It includes the hoist drum, motor, gearboxes, and associated control systems.

Step 4: Installation of Swing Motor, Operator Cabin

The swing motor is installed to provide the rotational movement of the crane. The operator cabin is then attached to the slewing unit, providing the operator with a clear view of the work area and controls for all crane functions.

Step 5: Installation of Counter Jib

The counter jib is a smaller boom that extends opposite the main jib. Its primary function is to provide counterbalance for the main jib and the loads it carries. This helps to prevent the crane from tipping over.

Step 6: Installation of Tower Peak/Apex

The tower peak, or apex, is installed at the highest point of the tower. It provides a mounting point for various components, such as the luffing mechanism, lights, and antennas.

Step 7: Installation of Jib

The main jib, or boom, is attached to the tower. This is the primary structural member that supports the trolley and the loads being lifted. The jib is often adjustable in length to accommodate different working radii.

Step 8: Connection of Counter Ties with Counter Jib

Counter ties are structural members that connect the counter jib to the tower. These ties help to stabilize the counter jib and distribute the loads more evenly.

Step 9: Installation of Counterweight

The counterweight is installed on the counter jib to balance the loads lifted by the main jib. The amount of counterweight required depends on the capacity of the crane and the length of the jib.

Commissioning and Inspection after Assembly

Functional Testing of Mechanisms

Once the tower crane has been assembled, it is essential to conduct thorough functional tests to ensure that all mechanisms are operating correctly. These tests typically involve:

- Hoisting: Verifying the smooth and controlled operation of the hoisting mechanism, including the hoist drum, motor, and ropes. The hoisting capacity and lifting speed should be tested to ensure they meet the specified parameters.

- Slewing: Assessing the rotation of the crane on its slewing ring. The slewing speed, accuracy, and smoothness of the rotation should be checked.

- Luffing: For cranes equipped with luffing mechanisms, testing the ability to change the boom angle is crucial. The luffing speed and the stability of the crane during the luffing operation should be evaluated.

Inspection of Tower Crane Parts During Testing

While conducting these functional tests, it is imperative to closely monitor the condition of the tower crane parts. This includes:

- Structural components: Checking for any signs of deformation, cracks, or excessive wear on the tower sections, boom, and counterweight frame.

- Connections: Inspect all bolted connections, pins, and welds to ensure they are tight and secure.

- Hydraulic and electrical systems: Verifying the proper functioning of hydraulic cylinders, pumps, and electrical control systems.

- Wear components: Assessing the condition of brake pads, sheaves, and rollers to ensure they are not excessively worn.

Safety Device Inspection

Safety devices are critical for the safe operation of a tower crane. These devices should be thoroughly inspected to ensure they are functioning correctly and are properly integrated with the tower crane parts. Specific safety devices that should be checked include:

- Limit switches: These devices prevent the crane from operating beyond its safe working limits. They should be tested to ensure they activate at the correct positions.

- Overload protection: The overload protection system should be tested to verify that it prevents the crane from lifting loads that exceed its rated capacity.

- Emergency stop: The emergency stop button should be activated to ensure that it brings all crane movements to a halt immediately.

- Anti-two-block device: This device prevents the hoist hook from being lowered into the load hook, which could cause a serious accident.

Coordination Between Safety Devices and Tower Crane Parts

It is essential to ensure that the safety devices are properly coordinated with the various tower crane parts. For example, the limit switches should be connected to the hoisting mechanism, slewing mechanism, and luffing mechanism to prevent over-hoisting, over-slewing, and overluffing. The anti-two-block device should be mechanically linked to the hoisting mechanism to prevent accidental lowering of the hook into the load.

Adherence to Standardized Procedures for Safety

Strictly adhering to standardized operating procedures is paramount throughout the assembly process. These procedures are designed to minimize the risk of accidents and ensure that the crane is assembled correctly and safely.

CPTC will continue to provide you with more information about tower cranes and their components.

Related Products

Tower Crane Trolleying Limit Gear

Controls luffing motion

Improves safety and efficiency

Enables dynamic boom…

Tower Crane Trolley

Multiple functions

Intuitive operation

Tower Crane Trolley Mechanism

Casting Tower Crane Pulley

High strength;…

Tower Crane Trolley Device

Multiple functions

Intuitive operation