Injecting Product

CPTC has its own production facilities and supports product customization services. We can provide OEM with Samples or Drawings Injection molding, including Plastic/Nylon Parts Injecting injection molding. Injection molding technology is widely used in modern manufacturing due to its advantages of high efficiency, flexibility, and cost-effectiveness, including automotive parts, electrical parts, daily necessities and other fields.

For information on Injecting Product services, please contact us.

Plastic/Nylon Parts Injecting

Custom manufacturing

High strength

Heat resistance

| Benefits of CPTC Injecting Product

- Tailor-made precision: Precisely tailored to customer needs, achieving personalized production and enhancing product competitiveness. The design and manufacturing of injection molds are flexible and can be customized according to product shape, size, function, and other requirements.

- High production efficiency: In the injection molding process, plastic raw materials are melted at high temperatures and injected into the mold under high pressure. After cooling, the mold is opened and the product is taken out. The whole process is highly automated, with a short production cycle, making injection molding technology the preferred choice for mass production of plastic products.

- Wide applicability: Suitable for most thermoplastic plastics, and can also be used with other materials to improve the performance of plastics. Widely used in various fields such as electrical appliances, automobiles, medical care, and so on.

- Durability: Made of high-strength materials, the products have good physical properties, high strength, and rigidity, are durable, and reduce maintenance costs.

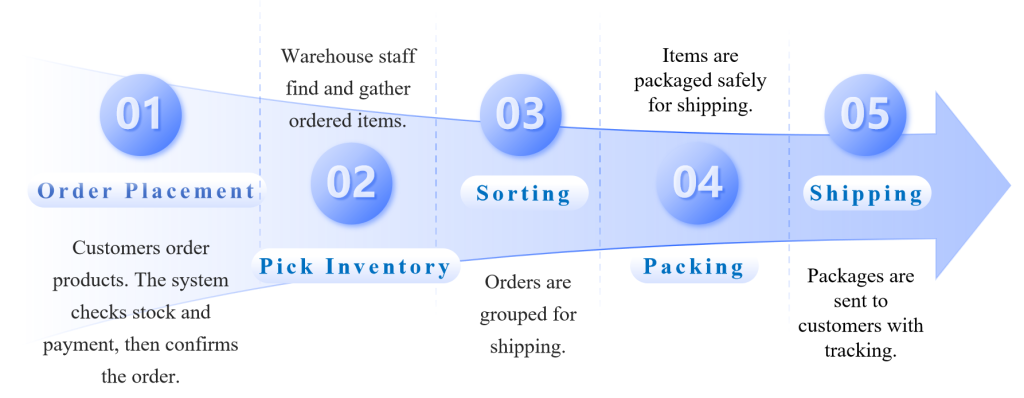

| Ordering Process

| Packing & Delivery