Laser Cutting Product

CPTC offer comprehensive laser cutting services, catering to both OEM with Samples or Drawings needs. Our expertise encompasses a wide range of laser cutting applications, including: Steel Plate Laser Cutting and Pipe Laser Cutting.

Laser cutting is an advanced metal processing technology that uses high-energy-density laser beams to cut various materials. It has the advantages of high precision, high speed, low loss and no contact. To learn more about laser cutting services please contact us.

Steel Plate Laser Cutting

Laser cutting technology

Steel plate cutting

Low cost

Customized laser cutting services

Steel plate cutting

Low cost

Customized laser cutting services

Pipe Laser Cutting

Pipe laser cutting

OEM laser cutting services

Customized production

OEM laser cutting services

Customized production

| Benefits of Laser Cutting Product

- High precision: The laser beam employed in laser cutting is incredibly precise, enabling the creation of intricate shapes with fine features. This unmatched precision makes laser cutting ideal for applications that demand the highest levels of accuracy, such as the fabrication of electronic components and medical devices.

- High speed: Laser cutting boasts cutting speeds that far surpass those of conventional cutting methods, such as milling and sawing. This remarkable speed translates into enhanced production throughput, enabling manufacturers to meet tight deadlines and maximize output.

- Contactless Cutting: Unlike traditional cutting methods that involve physical contact with the material, laser cutting operates in a contactless manner. This eliminates the risk of material deformation or stress, preserving the integrity of the workpiece and ensuring consistent results.

- Versatile Applicability: Laser cutting demonstrates remarkable versatility, effectively cutting a wide range of metal materials, including stainless steel, aluminum, titanium, and brass. This broad applicability makes laser cutting an indispensable tool for diverse industries, from aerospace and automotive to medical and electronics.

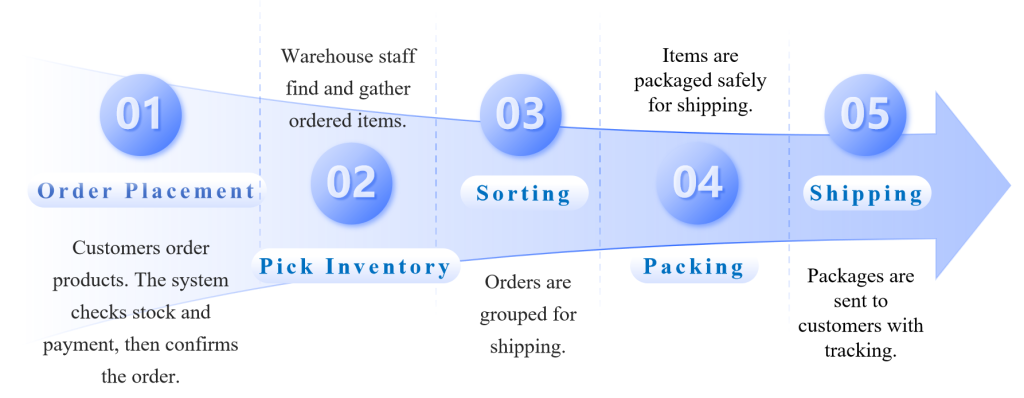

| Ordering Process

| Packing & Delivery