Lifting Mechanism

CPTC supplies lifting Mechanism are at the forefront of construction and material handling, providing reliable and efficient vertical transportation solutions. Our hoisting mechanisms are widely used in construction hoists, material and passenger hoists, and are renowned for their smooth operation, precise control, and exceptional durability.

CPTC is a lifting mechanism manufacturer in China. Our products are of high quality and stability, and can be delivered quickly according to stock. We sincerely hope to cooperate with friends in related fields!

Worm Wheel

Precise control for smooth operation

Simple structure for high transmission efficiency

Excellent anti-reverse performance

Wire Rope

High Tensile Strength and Durability

Compliance with Safety Standards

Sheave Assembly

Effortless and efficient

Advanced design and manufacturing technology

Multiple safety protection devices

Rope Presser

Wire rope protection

Strengthens wire rope

Improves safety and efficiency

Hoist Gearbox

Stable and reliable operation, secure

High flexibility, adjustable speed

Wide range of applications

| Benefits of the Lifting Mechanism Supplied by CPTC

- It is equipped with full safety devices to guarantee safe working;

- Stable running and comfortable adaptability;

- The transmission system adopts two-drive motors and three-drive motors. Planar double-enveloping worm gear reducer is adopted ensuring high efficiency, max payload, and long service life;

- The simple electrical control system, easy operation, and convenient maintenance with a low failure rate.

| Parameter

| Model | construction hoist spare parts motor driving mechanism |

| Power | 11kw/15kw |

| speed | 1400r/min |

| Brakemoment | 120Nm |

| D.Speed | 1403r/min |

| Frequency | 50Hz |

| Connection | Y |

| Brake Gap | 1.5mm |

| Voltage | 380V |

| Current | 24A a.c/1A.D.C |

| Lnsulation Class | F/F |

| Model | construction hoist gearbox |

| Ratio | 16: 1 |

| Rating | 11kw |

| Input | 1500r/min |

| Center distance | 125 |

Notice

a. It is recommended to utilize the viscosity VG320 synthetic worm gear oil (or synthetic gear oil) for lubrication. Once the environment temperature is higher than 30°C, it is recommended to utilize the viscosity VG460 synthetic worm gear oil (or synthetic gear oil) for lubrication. And allowed maximum working oil temperature is 100°C.

b. Notice of installation of cheap gearbox prices for lifting machinery, worm gearbox :

①The base-plate must be plane and stoutness and the base-plate must be screwed down and shockproof.

②The connecting shaft of prime mover, reducer and operation device must be coaxial installation.

③The diameter tolerance zone of input and output shaft is H6, the holes of fittings( such as couplings, belt-pully, sprocket wheel and so on) must properly mate the shaft, which prevents bearing from breakage because of an over-loose mate.

④Drivers such as sprocket wheels and gear must be fitted close to bearings in order to reduce the bending stress of hanging shaft.

⑤ While assembling the motor of WPD reducer, it is necessary that the proper amount of butter applies to the warm shaft input hole and keyway, avoiding assembling too tightly and rusting after using it for a long time.

⑥When ordering or using all kinds of WPD type, if the motor weight is bigger than the common, a supporting set is required.

c. Notice of usage of cheap gearbox prices for lifting machinery, worm gearbox :

- Before using, please check carefully whether the reducer model, distance, ratio, input connecting method, output shaft structure, input and output shaft direction and revolving direction accord with required.

- According to the requirement of selecting lubricant oil in the product manual. Please fill the proper category and brand lubricant. And then screw on the vent-plug, unlock the small cone-plug of vent-plug. Only after doing these, the reducer is already for starting up running. The proper brand and adequate lubricant oil are required, replacing oil in time conforming to the request of a product manual is also necessary, especially after using the first 100hours, it is required refilling new oil.

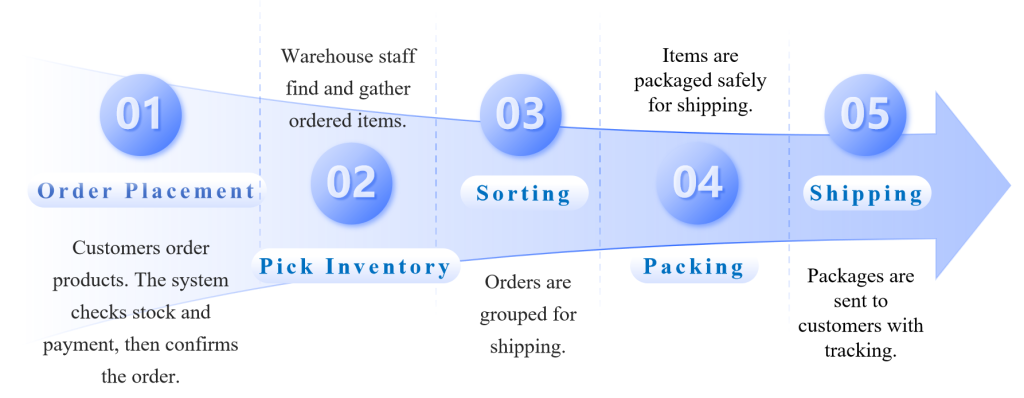

| Ordering Process

| Packing & Delivery