Construction material hoists play a crucial role in transporting materials to and from various levels of a building, making them a vital component of any construction project. However, the safe operation of hoists requires meticulous attention to detail and adherence to strict safety protocols.

A comprehensive approach encompassing pre-use assessments, routine inspections, and adherence to strict operational procedures is essential. By conducting thorough pre-use assessments, organizations can identify potential hazards and take appropriate measures to address them before the hoist operation commences. Regular inspections ensure that the equipment remains in good working condition and that any defects or wear and tear are promptly identified and repaired. Additionally, strict adherence to operational procedures helps to prevent human error and ensures that building construction hoists are operated safely and efficiently.

1. Pre-use Site Assessment

Key Factors to Consider During the Pre-Use Site Assessment

- Ground conditions: The ground must be level and stable to provide a secure foundation for the hoist. Any uneven terrain or soft ground could compromise the stability of the equipment and increase the risk of accidents.

- Surrounding environment: The area surrounding the hoist should be free of obstructions that could interfere with its operation or pose a safety hazard. This includes buildings, power lines, trees, and other structures.

- Power supply adequacy: The available power supply must be sufficient to meet the energy requirements of the hoist. Inadequate power can lead to equipment failure or reduced performance.

- Potential hazards: A thorough assessment should identify any potential hazards, such as nearby excavation sites, underground utilities, or hazardous materials. These hazards must be mitigated or avoided to ensure the safety of workers and equipment.

Specific Considerations for the Hoist’s Installation

- Foundation stability: The hoist’s foundation must be solid and capable of supporting the weight of the equipment and the loads it will be handling.

- Drainage: Adequate drainage measures should be in place to prevent water accumulation around the hoist. Water can cause corrosion and instability, and it can also create slippery surfaces that increase the risk of accidents.

- Safe distances: The hoist should be installed at a safe distance from buildings, power lines, and other structures to prevent collisions or electromagnetic interference. These distances should be determined based on the specific characteristics of the hoist and the surrounding environment.

2. Daily Inspections

Key Components to Inspect on a Daily Basis

- Steel ropes: Steel ropes are critical components of hoists, and they are subject to wear and tear over time. Regular inspections should focus on identifying signs of wear, such as fraying, broken wires, or corrosion. These conditions can compromise the strength and integrity of the rope, increasing the risk of failure.

- Hoists and winches: Hoists and winches are the primary components responsible for lifting and lowering loads. Regular inspections should ensure that these components are securely fastened and that there are no loose bolts or connections. Additionally, operators should check for any signs of damage or wear, such as cracks or excessive wear on the gears.

- Sheaves and guide devices: Sheaves and guide devices play a crucial role in directing the steel ropes and ensuring smooth operation of the hoist. These components should be inspected for obstructions, such as debris or foreign objects that could interfere with their function. Additionally, operators should check for any signs of damage or wear, such as cracks or excessive wear on the sheaves.

- Buckets: Buckets are used to transport materials, and they should be inspected for structural integrity and deformation. Regular inspections should identify any signs of damage, such as cracks, dents, or leaks. Additionally, operators should ensure that the bucket is securely attached to the hoist and that the safety latches are functioning properly.

- Safety gates and bucket doors: Safety gates and bucket doors are critical components for preventing accidents and ensuring the safety of workers. These components should be inspected to ensure that they function correctly and that they are not damaged or obstructed. Additionally, operators should ensure that the safety gates are properly secured when the hoist is in operation.

3. Monthly Inspections

Key Areas to Examine During Monthly Inspections

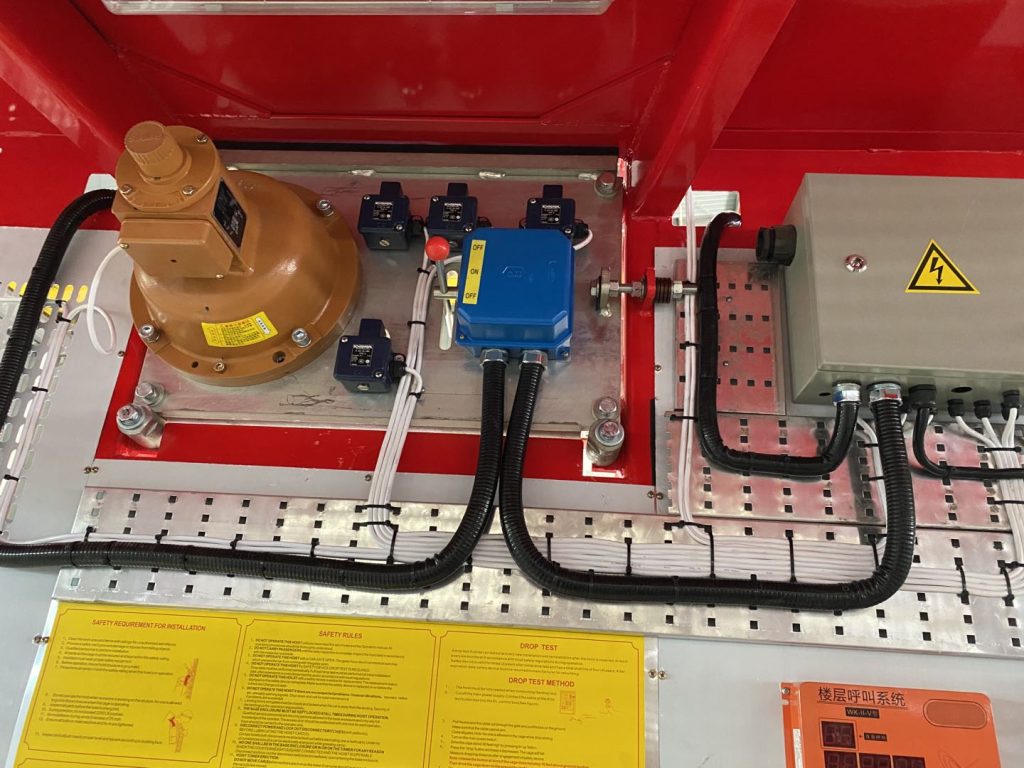

- Electrical systems: Electrical systems are critical components of hoists, and they should be inspected for any signs of damage or deterioration. This includes checking for tight connections, ensuring the integrity of the insulation, and verifying the condition of electromagnetic valves and other electrical components in hydraulic stations. Electrical failures can pose a serious safety hazard, so it is essential to address any issues promptly.

- Drivetrain: The drivetrain is responsible for transmitting power to the hoist’s lifting mechanism. Regular inspections should verify that the transmission mechanisms are operating smoothly and that the brakes and clutches are reliable. Any issues with the drivetrain can affect the hoist’s performance and safety.

- Guide frames: Guide frames play a crucial role in supporting the hoist and guiding the steel ropes. These components should be inspected for deformation, welding defects, cracks, and severe corrosion. Any damage to the guide frames can compromise the stability of the hoist and increase the risk of accidents.

- Anchoring systems: Anchoring systems are essential for securing the hoist to the ground and preventing it from tipping over. These systems should be inspected to ensure that attachment frames and guy ropes comply with relevant regulations and that ground anchors are secure. Any issues with the anchoring system can pose a serious safety hazard.

4. Equipment Safety Procedures

These procedures should cover a variety of topics, including:

- Pre-operation preparations: Before operating the hoist, operators should conduct a thorough pre-operation inspection to ensure that the equipment is in good working condition and that the worksite is safe.

- Operational precautions: Operators should be aware of and follow all relevant safety precautions during hoist operation. This includes maintaining a safe distance from the hoist, avoiding overloading the equipment, and using proper lifting techniques.

- Troubleshooting: Operators should be trained to identify and address common problems that may occur during hoist operation. This includes troubleshooting electrical issues, mechanical problems, and safety concerns.

- Maintenance: Regular maintenance is essential for ensuring the long-term safety and reliability of construction material hoists. This includes performing routine maintenance tasks, such as lubricating moving parts and replacing worn components.

Construction hoist operators must be professionally trained and certified to ensure that they possess the necessary skills and safety awareness to operate hoists safely and effectively. This training should cover topics such as hoist operation procedures, safety regulations, and emergency response.

Guaranteeing the Safe Use of Construction Material Hoists

Guaranteeing the safe use of construction material hoists is a systematic process involving pre-use assessments, daily and monthly inspections, strict adherence to operating procedures, and continuous improvement. By meticulously addressing every aspect of hoist operation, organizations can significantly reduce safety risks, ensure reliable equipment performance, and safeguard the lives of workers on construction sites. Compliance with national and local standards and regulations is essential, and these guidelines should be adapted to suit specific project requirements.

Of course, it is also necessary to choose a professional and reliable construction material hoists supplier. CPTC can provide you with various types of Construction Hoists. If you need it, please contact us in time.

Related Products

Curve Hoist

Self-Leveling

Versatile Applications

Adjustable Cage

SC Series Frequency Conversion Hoist

Frequency conversion control system.

Smooth starting and braking, less mechanical…

Lean Construction Hoist Lift

Compact structure

Easy to operate

Easy to assemble and disassemble

Builder Hoist Lift

Flexible

Multifunctional

Easy to operate