Suspended platforms, also known as gondolas or cradles, are widely used in high-altitude operations for various tasks such as building facade maintenance, cleaning, painting, and installation. Ensuring the safe operation of these platforms is paramount to prevent accidents and protect the lives of workers.

This article outlines the fundamental aspects of suspended platforms, their working principles, and highlights key safety production hazards that must be considered during operation and maintenance. Regular inspections using comprehensive checklists are crucial for identifying and mitigating these risks.

1. What is a Suspended Platform?

A suspended platform is a temporary elevated work platform suspended from a building or structure by means of ropes or cables. It provides a stable and mobile working environment for personnel at significant heights.

Components of a Suspended Platform

A typical suspended platform system comprises several key components:

- Suspended Platform (Basket/Cradle): The working platform itself, usually made of steel or aluminum, providing space for workers and materials.

- Suspension Mechanism: This includes the front and rear support frames (parapets or outriggers) placed on the roof or supporting structure, counterweights to stabilize the frames, and suspension ropes (steel wire ropes) that hang down to support the platform.

- Lifting Mechanism (Hoists): Electrically powered hoists that grip and climb along the suspension ropes, allowing the platform to move vertically.

- Safety Devices: Essential components designed to prevent accidents, including safety locks (anti-falling devices), limit switches, anti-tilting devices, and safety ropes with harnesses for individual workers.

- Electrical Control System: Controls the movement of the platform, including up/down functions and emergency stop mechanisms.

- Wire Ropes: Consisting of the main suspension ropes and the safety ropes.

Working Principle of a Suspended Platform

The suspension mechanism is installed and secured on the roof of the building or supporting structure, with counterweights providing stability. The suspension ropes are then fed through the hoists attached to the suspended platform. The electric motors within the hoists drive a gripping mechanism that allows the platform to ascend or descend along the suspension ropes. The electrical control system allows operators to control this movement. Safety devices are in place to automatically engage in case of rope failure or other critical situations, preventing the platform from falling.

2. 6 Key Safety Production Hazards to Consider for Suspended Platforms

Regular and thorough inspections are vital to identify and address potential safety hazards. A comprehensive suspended platform inspection checklist should be used before each use and at regular intervals. Here are six key categories of safety production hazards:

2.1 Structural Component Hazards

2.1.1 Permanent deformation of the suspended platform components: Bending, cracking, or other forms of permanent deformation in the platform structure can compromise its integrity and load-bearing capacity.

Inspection Checklist Item: Check all structural members for bends, cracks, dents, or any signs of permanent deformation.

2.1.2 Severe corrosion of the suspended platform components: Rust and corrosion weaken the metal components, reducing their strength and increasing the risk of failure.

Inspection Checklist Item: Inspect all metal parts for signs of rust and corrosion, paying close attention to welds and joints.

2.2 Suspension Mechanism Hazards

2.2.1 Missing front support frame of the suspended platform: The absence of a properly installed front support frame can lead to instability and a high risk of the platform tipping or detaching.

Inspection Checklist Item: Verify that all required support frames are in place and correctly installed according to the manufacturer’s instructions.

2.2.2 Unstable front support frame of the suspended platform: Loose connections, inadequate counterweights, or improper setup of the support frame can cause it to shift or collapse.

Inspection Checklist Item: Ensure that all connections on the support frames are securely fastened and that the counterweights are of the specified weight and correctly positioned.

2.2.3 Front support frame not perpendicular to the supporting surface: An angled support frame can unevenly distribute the load, potentially overloading certain components and increasing the risk of failure.

Inspection Checklist Item: Use a level to check that the support frames are perpendicular to the roof or supporting surface.

2.3 Suspended Platform Hazards

2.3.1 The working surface of the suspended platform is not equipped with vertical protection devices: Lack of guardrails, toe boards, or safety nets around the platform’s edge increases the risk of workers or materials falling.

Inspection Checklist Item: Confirm that guardrails of the required height and strength are securely installed on all open sides of the platform, along with toe boards.

2.4 Safety Device Hazards

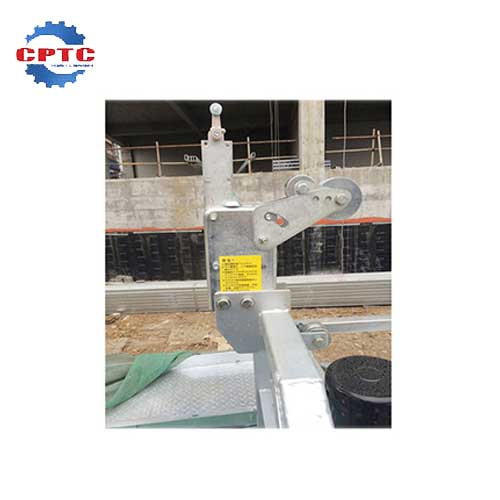

2.4.1 Anti-falling device (Safety Lock) malfunction: A faulty safety lock may fail to engage in case of suspension rope failure, leading to a catastrophic fall.

Inspection Checklist Item: Test the safety lock mechanism to ensure it engages smoothly and reliably when the suspension rope is slackened or broken.

2.4.2 Limit device failure: Malfunctioning upper or lower limit switches can allow the platform to travel beyond its safe operating range, potentially causing collisions or damage.

Inspection Checklist Item: Test the upper and lower limit switches to ensure they stop the platform’s movement at the designated points.

2.4.3 Safety rope defects: Damaged, frayed, or improperly secured safety ropes cannot provide adequate fall protection for workers using safety harnesses.

Inspection Checklist Item: Inspect the entire length of the safety ropes for any signs of damage, wear, or corrosion. Ensure they are correctly attached to independent anchor points and equipped with appropriate self-locking connectors.

2.5 Lifting Mechanism Hazards

2.5.1 Wire rope guiding issues: Improperly guided wire ropes can become tangled, kinked, or jump out of the hoist mechanism, leading to uneven lifting, damage to the ropes, or platform instability.

Inspection Checklist Item: Check that the wire ropes are correctly seated in the hoist’s guiding mechanisms and that there are no signs of entanglement or damage.

2.5.2 Lifting mechanism connection failures: Loose or damaged connections between the hoist and the platform can result in the hoist detaching, causing the platform to fall.

Inspection Checklist Item: Inspect all bolts, pins, and other connecting hardware on the hoists for tightness and any signs of damage or wear.

2.6 Electrical Control System Hazards

2.6.1 Electrical protection deficiencies: Faulty wiring, damaged insulation, or non-functional grounding can lead to electric shock hazards.

Inspection Checklist Item: Inspect all electrical cables for damage, ensure proper insulation, and verify the functionality of grounding and residual current devices (RCDs).

2.6.2 Control system malfunctions: Defective control buttons, faulty wiring, or other issues within the control box can cause erratic platform movement or failure of safety features.

Inspection Checklist Item: Test all control functions (up, down, emergency stop) to ensure they operate smoothly and as intended.

3. Final Remarks

The safe operation of suspended platforms relies heavily on thorough pre-operation checks, regular maintenance, and the identification and mitigation of potential hazards. Utilizing a detailed suspended platform inspection checklist is essential for ensuring that all critical components are in safe working order.

CPTC, as one of the suspended platform manufacturers in China, has become a significant player in the global market, offering a wide range of products. Our suspended platforms strictly comply with international safety standards and provide product quality certifications. By prioritizing safety through diligent inspections and responsible sourcing, we can significantly reduce the risks associated with high-altitude work using suspended platforms and ensure the safety of all personnel involved.

Related Products

ZLP Series Suspended Platform

Simple and quick installation

Multiple security measures

Stable and…

Suspended Platform Safety Lock

Easy to Operate and Use

Made…

Limit Switch

Compact and Lightweight

Easy Installation

Safety Rope

Lightweight and Portable

Durable and Long-lasting