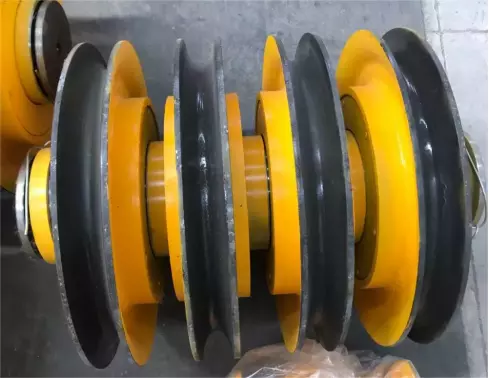

Sheave Assembly

- Wide range of applications

- Effortless and efficient

- Advanced design and manufacturing technology

- Multiple safety protection devices

Product Description

Sheave Assemblies are common components of simple machines. They work by changing the direction of a force, thereby changing the effect of the force.

CPTC-manufactured sheave assemblies are commonly used in equipment such as cranes, slings, and hoists. When a force is applied to the drive shaft, the pulley rotates, causing the object connected to the driven shaft to move. This is very helpful for lifting heavy objects or performing other tasks that require more force.

| Features of Sheave Assembly

- Power Transmission Function:Crane pulleys effectively transmit power from the crane to the load. By utilizing the principle of pulleys, the force is distributed in multiple directions, reducing the load on the crane itself and improving its operational efficiency.

- Force Conversion Function:Crane pulleys can transform the applied force into different directions and magnitudes to meet the requirements of various working conditions. By adjusting the combination and quantity of pulleys appropriately, crane pulleys can achieve flexible force conversion.

- Stability and Safety:Crane pulleys employ advanced design and manufacturing techniques to ensure smooth operation and minimize the risk of malfunctions. Additionally, crane pulleys are equipped with multiple safety protection devices, such as brakes and overload protection mechanisms, to guarantee safe crane operation.

- Wide Range of Applications:Crane pulleys are extensively used in large-scale projects such as construction sites and ports for lifting and transporting heavy loads. They also find applications in manufacturing, logistics, and other industries to enhance production efficiency.

- Diverse Structures:Crane pulleys come in a variety of structural forms, allowing for selection and combination based on specific needs to cater to diverse application requirements.

| Why Choose Us

CPTC is at the forefront of technological advancements in construction machinery. Our commitment to research and development drives us to create innovative products that improve safety, efficiency, and sustainability on construction sites. There are our advantages:

Cost-Effective Solutions

Our extensive spare part inventory and efficient supply chain enable us to offer competitive pricing without compromising quality, providing significant cost savings for our customers.

Streamlined Ordering Process

Our user-friendly online ordering platform allows you to place orders quickly and easily, track your shipments, and access product information 24 hours.

Comprehensive Product Verification

From initial material assessment to final shipment, our products undergo multiple levels of inspection to ensure optimal quality.

Round-the-Clock Assistance

Our dedicated support team is always available to assist you, whether it’s day or night.

Expert Installation and Setup

Our skilled technicians will guide you through the installation process, ensuring proper setup and optimal operation.