Suspended platforms, also known as cradles, are essential tools in various industries for high-rise construction, maintenance, and cleaning. While they significantly enhance efficiency and productivity, they also pose inherent risks to workers. To mitigate these risks and safeguard workers at height, suspended platform safety locks have become indispensable safety devices.

What is a Suspended Platform Safety Lock?

The suspended platform safety lock is an important safety device. When the working wire rope breaks or one end of the suspended platform slides down and causes the suspended platform to fall, it can automatically close and lock the safety wire rope to stop the suspended platform and prevent it from falling.

It is usually a mechanical or electromechanical device that automatically engages to fix the platform to its supporting structure in the event of a sudden cable failure or other emergency, thereby preventing the suspended platform and its occupants from accidentally falling.

How Does a Suspended Platform Safety Lock Work?

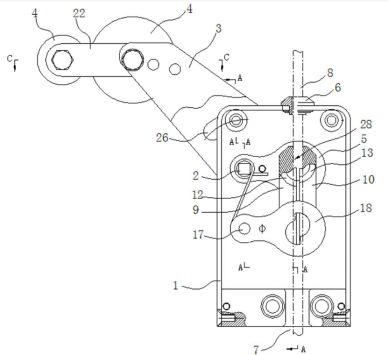

During normal operation, the roller on the swing arm is pressed by the working steel rope, lifting the swing arm and causing the lock rope mechanism to release, placing the safety lock in the unlocked position. This allows the safety steel rope to pass freely through the safety lock. When the working steel rope breaks or the suspended platform tilts beyond a certain angle, the pressure of the working steel rope on the roller is eliminated, causing the swing arm to drop back to its original locked position. This activates the lock rope mechanism to grip the safety steel rope, locking it in place and preventing the suspended platform from falling.

The working principle of a suspended platform safety lock varies depending on its specific design.

Mechanical Safety Locks:

- These locks rely on a mechanical mechanism, such as a spring-loaded clamp or a gravity-activated brake.

- When a sudden drop or excessive movement of the platform is detected, the mechanical components are triggered, causing the lock to engage and clamp onto the supporting structure.

Electromechanical Safety Locks:

- These locks combine mechanical and electrical components.

- They utilize sensors to monitor the platform’s movement and position.

- If a sudden drop or abnormal movement is detected, the electrical system activates the mechanical locking mechanism.

Functions of a Suspended Platform Safety Lock

The suspended platform safety lock is a safety device used in construction. It is installed on the hanging basket and plays an important role in protecting the safety of construction workers. It can fix the suspended platform so that the hanging basket will not shake or move due to external interference, thus ensuring the safety of construction workers inside the suspended platform.

Securing the Suspended Cradle: The primary function of a safety lock is to securely hold the suspended platform in place, preventing it from falling. This is crucial in case of cable failure, power outages, or other unforeseen circumstances.

Preventing Detachment from the Steel Rope: Safety locks are designed to firmly grip the supporting steel rope, ensuring that the platform remains attached even in the event of a cable rupture.

Enhancing Operational Safety: By providing a reliable safety net, safety locks significantly contribute to a safer working environment for workers at height. This reduced risk can boost worker morale, improve productivity, and reduce the likelihood of accidents.

How to Use a Suspended Platform Safety Lock Correctly

The suspended platform safety lock is a critical safety component that safeguards the lives of workers engaged in high-altitude operations. Its primary function is to ensure the stability and security of the suspended platform. Proper use of safety locks not only enhances work efficiency but also guarantees the safety of personnel working at heights.

When using suspended platform safety locks, it is imperative to ensure that they are in good working condition and that all operating procedures are strictly adhered to, thereby preventing injuries to personnel.

Correct Installation:

- Professional Installation: Ensure that the safety lock is installed by qualified professionals.

- Manufacturer’s Instructions: Adhere strictly to the manufacturer’s instructions for installation, including proper alignment, tensioning, and anchoring.

- Compatibility: Verify that the safety lock is compatible with the specific suspended platform model and its supporting structure.

Regular Inspection:

- Visual Inspection: Conduct regular visual inspections to check for any signs of wear, damage, or corrosion on the safety lock and its components.

- Functional Testing: Periodically test the safety lock’s functionality to ensure it is working correctly. This may involve simulating emergency scenarios or using specialized testing equipment.

Daily Maintenance:

- Lubrication: Lubricate moving parts, such as hinges and clamping mechanisms, to ensure smooth operation and prevent rust.

- Cleaning: Clean the safety lock to remove dirt, debris, and corrosive substances that may affect its performance.

- Tightening: Check for loose bolts, nuts, and other fasteners and tighten them as needed.

Operational Precautions:

- Operator Training: Ensure that all operators are properly trained in the safe operation of suspended platforms and safety locks.

- Load Limits: Never exceed the maximum load capacity of the platform.

- Weather Conditions: Avoid operating suspended platforms in adverse weather conditions, such as strong winds or heavy rain.

- Emergency Procedures: Establish clear emergency procedures and ensure that all workers are aware of them.

By following these guidelines and prioritizing safety, you can significantly reduce the risks associated with suspended platform operations and protect workers at height. Remember, a well-maintained and properly used safety lock is a crucial component of a safe and efficient work environment.

Related Products

Limit Switch

Compact and Lightweight

Easy Installation

Construction Platform

With a lightweight…

Safety Rope

Lightweight and Portable

Durable and Long-lasting

ZLP Series Suspended Platform

Simple and quick installation

Multiple security measures

Stable and…