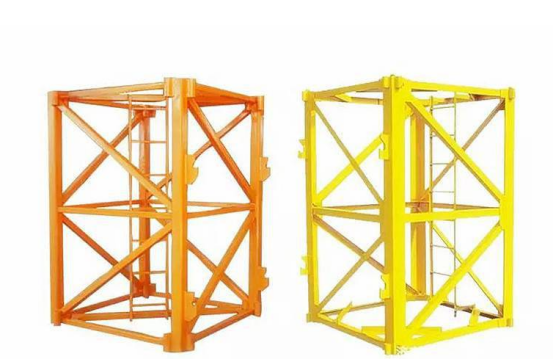

Tower cranes are indispensable in modern construction, playing a crucial role in lifting and transporting heavy materials. The foundation of a tower crane’s stability and functionality lies in its structural integrity, particularly the design and construction of its standard sections. These sections, typically fabricated from either angle steel or square tube, significantly influence the crane’s overall performance, load-bearing capacity, and longevity.

This article will delve into the characteristics, advantages, and disadvantages of both angle steel and square tube standard sections, providing valuable insights for engineers, contractors, and those involved in the selection and procurement of tower crane components.

What is a Crane Standard Section?

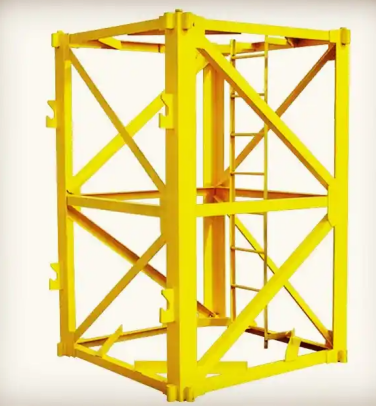

The standard section is a crucial component of a tower crane, primarily designed to withstand bending moments, torques, vertical forces, and horizontal forces transmitted from the upper working components of the crane. This enhances the crane’s stability, safety, and operational efficiency. Typically, a standard section is welded together using four seamless steel pipes as main limbs and a triangular steel frame. Its cross-section measures 0.65 meters by 0.6 meters, and the height is 1.508 meters. Standard sections come in various lengths, such as 2.2 meters, 2.5 meters, 2.8 meters, and 3 meters, with weights generally ranging from 450 to 500 kilograms.

The materials used for standard sections are primarily angle steel and square tube. Angle steel specifications include 140×10, 160×12, and 160×16, while square tube specifications include 135×10 and 135×12. The connections between standard sections are typically made using M20X210 (Grade 8.8) high-strength bolts to ensure a secure and reliable joint.

Angle Steel Crane Standard Section:

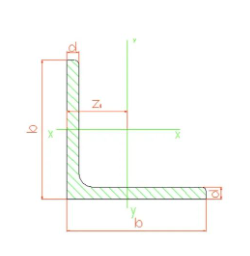

·Constructed using angle steel profiles, these sections offer a classic and widely used approach.

·Angle steel, with its L-shaped cross-section, provides a versatile framework for connecting different components of the tower crane.

Square Tube Crane Standard Section:

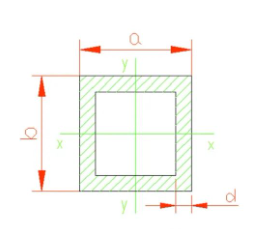

·Utilizing square or rectangular hollow steel tubes, these sections offer a more modern and potentially more robust alternative.

·The closed-section profile of square tubes enhances torsional rigidity and can provide superior load-bearing capacity in certain applications.

Comparative Analysis of Angle Steel and Square Tube Standard Sections

Angle steel and square tube, while both used in tower crane standard sections, present distinct characteristics in terms of their production processes, material composition, geometric profiles, and suitability for various applications. Consequently, the selection of the appropriate material should be tailored to the specific demands of each construction project. In the following sections, we will delve into the specific differences between these two materials.

Comparison of production and processing technology:

·Both types of sections undergo similar manufacturing processes, including cutting, welding, and finishing.

·Angle steel sections generally involve simpler welding procedures, while square tube sections might require more intricate welding techniques, especially for complex joints.

·The choice of manufacturing technology can significantly impact the overall cost and production time.

Comparison of materials:

·The selection of steel grade is crucial to ensuring the strength and durability of crane sections. Standard section angle steel is typically made of Q235B steel, which possesses excellent plasticity and weldability, along with good strength and toughness.

· Square tubes, on the other hand, come in a wider range of grades, including Q235B, Q345B, and Q420B. Careful consideration must be given to material properties such as yield strength, tensile strength, and fatigue resistance to meet the demanding requirements of tower crane operations.

Comparison of shapes:

· The cross-section of an angle steel standard section is “L”-shaped, with both edges forming right angles.

· A square tube has a rectangular cross-section with all four sides forming right angles and straight edges.

· The angle steel’s cross-sectional shape offers flexibility when connecting to other components, while the square tube’s cross-section provides higher torsional stiffness and a more uniform stress distribution.

Comparison of application fields:

·For smaller or less demanding cranes, angle steel profiles may be the preferred choice. However, for larger, heavier cranes with higher lifting capacities and more stringent operational requirements, square tube profiles are typically favored.

·Angle steel standard sections find applications in various industries, including construction, machinery, electricity, communications, aviation, petroleum, and chemicals.

·Square tubes are also widely used in construction, bridges, power generation, transportation, metallurgy, and machinery.

·Angle steel is suitable for applications that require the ability to withstand heavy loads and external impact.

·Compared to angle steel standard sections, square tube sections have a more complex structure. Square tubes offer superior load-bearing capacity and are lighter in weight, making them suitable for applications involving frequent movement or installation.

Advantages and Disadvantages of Angle Steel and Square Tube Standard Sections:

Angle Steel Tube Standard Sections:

- Advantages:

- Versatile and adaptable to various configurations. 1 Standard section angle steel is typically made of Q235B steel, which possesses excellent ductility and weldability, along with good strength and toughness, making it widely used in steel structures, machinery manufacturing, and vehicle manufacturing.

- Relatively easy to manufacture and weld.

- Generally more cost-effective compared to square tube profiles.

- Disadvantages:

- Prone to stress concentration at the bends.

- May have lower torsional rigidity compared to square tube profiles.

- The production of angle steel standard sections involves numerous node plates, and the connection between the bracing and the main limb is achieved through welding at these node plates. This results in approximately 30% more welding compared to square tube standard sections.

Square Tube Tube Standard Sections:

- Advantages:

- High torsional rigidity, enhancing the overall stability of the crane.

- Excellent load-bearing capacity. Square tube material is characterized by its strong load-bearing capacity and lightweight, making it suitable for applications requiring mobility or installation.

- Due to the absence of node plates in square tube standard sections, production efficiency is significantly higher.

- Disadvantages:

- The fabrication of square tube standard sections requires specialized welding equipment, leading to increased processing difficulty and higher costs.

- Square tube standard sections are not suitable for colder regions due to environmental concerns.

- Water can easily accumulate inside square tubes, and prolonged water retention can cause expansion and cracking, posing a significant safety risk to the tower crane.

- The interior of square tube standard sections is difficult to coat during the factory coating process. Prolonged use may result in rust formation, which can be difficult to detect due to its internal location. Over time, the thickness of the main limb of the standard section can gradually decrease, creating a potential safety hazard.

Summary

The choice between angle steel and square tube standard sections should be based on specific project requirements. For large construction sites and heavy industrial applications where significant loads and external impacts must be withstood, angle steel standard sections are the preferred choice. However, in applications requiring frequent movement, such as mobile installations or bridge construction, square tube standard sections may be more suitable.

CPTC is a professional tower crane parts manufacturer committed to providing a comprehensive range of tower crane spare parts to fully meet customer requirements for safety, stability, and reliability. If you have any further questions about selecting the right tower crane standard section, please feel free to contact us for professional support.

Related Products

Tower Crane Trolley Device

Multiple functions

Intuitive operation

High Quality Crane Operator Cabin for Tower Crane

High quality steel material for frame

The cab is…

Tower Crane Wall Tie

Vertical support

Safety enhancement

Casting Tower Crane Pulley

High strength;…