Tower cranes can efficiently lift and transport materials throughout the construction site making them for the smooth execution of various building processes. It is responsible for moving loads horizontally along the crane’s jib, enabling precise placement of construction materials across a wide area. Any malfunction or failure of this component can lead to significant delays in construction activities, increased costs, and potential safety hazards. Therefore, we must determine the tower crane trolley functions, the factors, and the right way to tower crane trolley maintenance for extended life. We will give you a detailed introduction as follows.

Basic Structure and Vulnerable Components of Tower Crane Trolley

Structural Overview

- Main Components: The tower crane trolley primarily consists of several key parts, including the trolley frame, wheels, and pulley systems.

- Functions and Interrelationships: Each of these components plays a specific role in the trolley’s operation. The frame provides structural support, the wheels enable horizontal movement along the jib, and the pulley systems facilitate lifting and lowering loads. These parts work in concert to ensure the efficient and safe transportation of materials.

Identification of Vulnerable Components

- Wire Rope: The wire rope is a crucial component that bears the weight of the load. It is susceptible to wear and tear due to friction and stress, which can lead to fraying or breakage. Regular inspection and maintenance are essential to prevent wire rope failures.

- Pulleys: Pulleys are subject to frequent rotation, which can cause wear over time. The condition of the pulleys should be regularly checked to ensure smooth operation and prevent damage to the wire rope.

- Braking System: The braking system is critical for controlling the movement of the trolley and ensuring safe load handling. Over prolonged use, the braking system may experience malfunctions or reduced effectiveness. Regular inspection and maintenance are necessary to maintain its reliability.

Regular Maintenance Schedule and Key Points

Daily Inspection

- Visual Inspection: Check for any obvious deformations, cracks, or other signs of damage on the tower crane trolley structure.

- Functional Testing: Verify the effectiveness of the braking system and the smooth rotation of the pulleys.

Weekly Maintenance

- Wire Rope Inspection and Maintenance: Regularly inspect the wire rope for wear, fraying, or breakage. Apply lubricant as needed to maintain its condition and prolong its lifespan.

- Fastener Inspection: Check all bolts and screws to ensure they are securely fastened. Tighten any loose connections to prevent potential issues.

Monthly In-depth Maintenance

- Pulley System Overhaul: Conduct a thorough inspection of the pulley system, including the pulleys, bearings, and sheaves. Repair or replace any worn or damaged components.

- Braking System Adjustment and Component Replacement: Inspect the braking system for wear and tear. Adjust the brakes as necessary and replace any worn parts to ensure reliable performance.

Maintenance Measures for Special Environments

High-Temperature Environments

- Impact of High Temperatures: High temperatures can negatively affect various components of the tower crane trolley, such as rubber parts and lubricating oil. Rubber parts may degrade or crack, while lubricating oil can lose its viscosity and lubricating properties.

- Corresponding Cooling and Protection Measures: To mitigate these effects, implement appropriate cooling and protection measures. Regularly inspect cooling systems, such as fans or radiators, to ensure they are functioning correctly. Use high-temperature resistant lubricating oil that can maintain its properties under extreme heat conditions. Consider additional shading or cooling mechanisms for the trolley if necessary.

Humid Environments

- Risk of Rust: Humid environments increase the risk of rust and corrosion on various parts of the tower crane trolley, particularly those made of steel.

- Moisture-Proof and Rust-Prevention Measures: To prevent rust and corrosion, apply protective coatings, such as paint or specialized rust inhibitors, to vulnerable areas. Regularly inspect painted surfaces for damage and reapply as needed. Utilize desiccants or dehumidifiers in enclosed areas, if applicable, to control moisture levels. Ensure proper drainage to prevent water accumulation on the trolley structure.

The Impact of Correct Operation on Maintenance

The Importance of Standardized Operation

- Reducing Wear and Tear: Correct startup, stopping, and steering procedures can significantly minimize the wear and tear on tower crane trolley components. Smooth and controlled movements reduce stress on the machinery, extending the lifespan of critical parts.

- Operator Training and Adherence to Procedures: Comprehensive training for operators is essential to ensure they understand the correct operating procedures. Strict adherence to these procedures is crucial for preventing unnecessary strain on the tower crane trolley and maintaining its optimal condition.

Hazards of Irregular Operation

- Damage from Abrupt Actions: Actions such as sudden stops or overloading can cause significant damage to the tower crane trolley. Abrupt movements can place excessive stress on the structural components, while overloading can lead to premature wear and potential failures.

Maintenance Records and Management

Content of Maintenance Records

Each maintenance record should include the following information:

- Date of Maintenance: The specific date when the maintenance work was performed.

- Maintenance Personnel: The names or identification of the individuals who carried out the maintenance.

- Maintenance Items: A detailed description of the tasks performed during the maintenance, such as inspections, repairs, replacements, or adjustments.

- Problems Found and Solutions: Any issues or defects discovered during the maintenance process, along with the corresponding solutions or corrective actions taken.

Role of Maintenance Records

Maintenance records serve several important purposes:

- Reference for Subsequent Maintenance: Past maintenance records provide valuable information about the tower crane trolley’s maintenance history, including recurring issues, previous repairs, and component replacements. This information can be used to guide future maintenance activities and prevent similar problems from occurring.

- Basis for Service Life Analysis: By tracking maintenance records over time, it is possible to analyze the tower crane trolley’s usage patterns, identify trends in component wear, and estimate its remaining service life. This analysis can help in making informed decisions about future maintenance, repairs, or replacements.

Trolley Maintenance: Key to Project Success

Maintaining a tower crane trolley involves a multi-faceted approach encompassing regular maintenance, specialized procedures for unique environments, and consistently correct operation. These three elements are crucial for ensuring the trolley’s long-term health and reliability. A well-maintained tower crane trolley directly translates to improved project outcomes.

Extending the trolley’s service life through diligent upkeep leads to significant cost reductions by postponing replacements and minimizing downtime. Furthermore, a properly maintained trolley operates safely and predictably, reducing the risk of accidents and fostering a secure job site for all personnel.

More information about the tower crane trolley you might find on the CPTC website:https://www.cptc-china.com/

Related Products

Tower Crane Trolley Device

Multiple functions

Intuitive operation

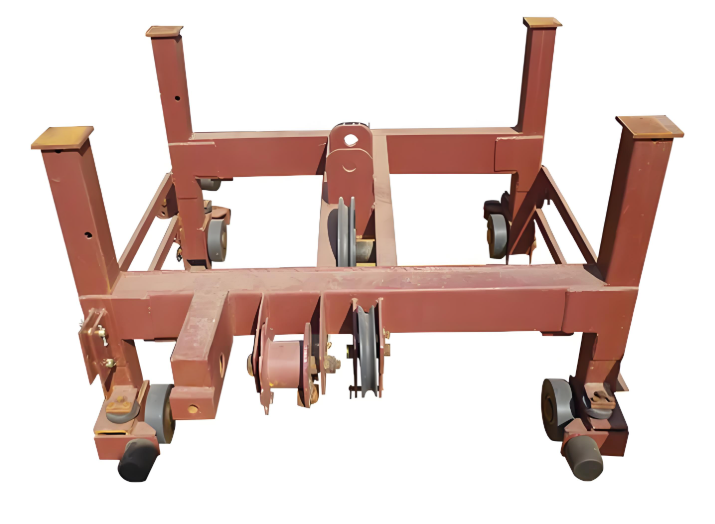

Tower Crane Trolley Chassis

Withstands heavy loads and forces

Works with supporting…

Trolleying Fan for Tower Crane

Tower Crane Trolleying Limit Gear

Controls luffing motion

Improves safety and efficiency

Enables dynamic boom…