Tower cranes are indispensable on modern construction sites, playing a crucial role in lifting and moving heavy materials. These towering machines, however, present inherent safety challenges. To mitigate risks and ensure safe operation, tower cranes are equipped with a range of sophisticated safety devices. Among these, limit switches play a vital role.

This article explores the function of limit switches and delves into the five essential safety limit devices found on tower cranes, providing guidance on selection and maintenance.

What are Limit Switches?

A limit switch is an electrical switching device used to control the movement range of mechanical equipment. It detects the position of the equipment’s movement and automatically cuts off the power or triggers an alarm when the equipment reaches a preset limit position, preventing it from operating beyond the safe range. Limit switches play a crucial role in heavy machinery such as tower cranes, ensuring safe operation and preventing accidents.

A limit switch typically consists of a mechanical trigger and an electrical switch. When the moving parts of a tower crane (such as the boom or luffing mechanism) come into contact with the trigger of the limit switch, the internal contacts of the switch open or close, cutting off the power or sending a signal to stop the equipment’s further movement. The working principle of a limit switch is based on mechanical contact or non-contact sensing (such as photoelectric or magnetic induction), ensuring the equipment stops promptly when reaching the limit position.

The 5 Key Safety Limit Devices in Tower Cranes:

Overload Limit

The overload limit device monitors the load of the tower crane. When the load exceeds the rated value, the overload limit device automatically cuts off the power or triggers an alarm to prevent the crane from tipping over or structural damage due to overloading. The overload limit device usually detects the load on the hook through sensors and transmits the signal to the control system.

Luffing Limit

The luffing limit device controls the range of the tower crane’s boom movement. When the boom reaches the preset maximum or minimum angle, the luffing limit device automatically stops the luffing mechanism, preventing over-extension or retraction of the boom and ensuring it operates within a safe range.

Height Limit

The height limit device restricts the maximum lifting height of the tower crane’s hook. When the hook rises to the preset maximum height, the height limit device automatically cuts off the power to prevent the hook from colliding with the crane’s top structure or other obstacles, avoiding equipment damage or accidents.

Moment Limit

The moment limit device monitors the torque of the tower crane. When the torque exceeds the rated value, the moment limit device automatically cuts off the power or triggers an alarm to prevent the crane from tipping over or structural damage due to excessive torque. The moment limit device typically calculates the current torque value by detecting the boom angle and load through sensors and compares it with the preset safety value.

Slewing Limit

The slewing limit device controls the rotation range of the tower crane. When the crane’s rotation angle reaches the preset maximum or minimum value, the slewing limit device automatically stops the slewing mechanism, preventing excessive rotation and ensuring the equipment operates within a safe range.

How to Choose the Right Limit Device for a Tower Crane

Tower cranes, as common heavy equipment on construction sites, are of paramount importance to safety. In order to ensure the stability and safety of tower cranes during operation, tower cranes are equipped with a variety of safety devices, of which the limit device is particularly critical. When selecting the limiter, the following factors need to be considered:

Select Based on the Type of Tower Crane and Working Environment

Different types of tower cranes (such as flat-top cranes or luffing jib cranes) and working environments (such as high-rise buildings or bridge construction) have varying requirements for limit devices. When selecting, factors such as the crane’s load capacity, working range, and usage frequency should be considered to ensure the limit device meets actual needs.

Consider the Accuracy and Reliability of the Limit Device

The accuracy and reliability of the limit device directly affect the safety of the tower crane. Priority should be given to limit devices with high precision and strong reliability to ensure they function accurately and promptly under various working conditions.

Compatibility and Maintenance Convenience

The limit device should be compatible with the tower crane’s control system and easy to install and maintain. When selecting, factors such as installation location, wiring method, and maintenance intervals should be considered to ensure seamless integration with the existing system and ease of daily maintenance.

Maintenance Tips for Tower Crane Limit Devices

By implementing the following measures, the service life of the limit device can be effectively extended, ensuring its safe and reliable operation.

Regular Inspection and Calibration

Limit devices should be regularly inspected and calibrated to ensure they are functioning properly. Inspection includes checking for wear on mechanical components, proper contact of electrical contacts, and sensitivity of sensors. Calibration should be adjusted according to the crane’s actual working parameters to ensure the limit device triggers accurately.

Cleaning and Lubrication

The mechanical components of limit devices should be regularly cleaned and lubricated to prevent dust, grease, or other contaminants from affecting their performance. Use a clean cloth or brush for cleaning, avoiding corrosive cleaners. Apply an appropriate amount of lubricant to ensure smooth movement of mechanical parts.

Timely Replacement of Damaged Parts

When mechanical or electrical components of the limit device are damaged, they should be replaced promptly. Replacement parts should be of the same model or equivalent performance as the original to ensure the device’s functionality. After replacement, testing should be conducted to confirm proper operation.

Record and Maintain Logs

After each maintenance and inspection, the working status, maintenance content, and replaced parts of the limit device should be recorded in detail. Maintenance logs help track the device’s usage, identify potential issues early, and provide references for future maintenance.

In summary

The five major safety limit devices of tower cranes are critical components for ensuring safe operation. By understanding the working principles of limit switches, selecting the appropriate limit devices, and performing regular maintenance, the safety risks during crane operation can be effectively reduced, ensuring the safety of construction personnel and equipment.

Related Products

Tower Crane LED Light

High luminous efficiency

Environmentally friendly and energy-saving

Long service…

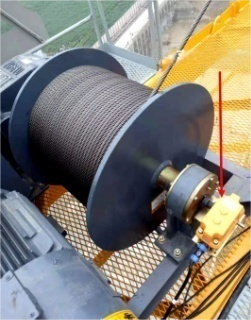

Tower Crane Hoisting Device

Smooth operation, precise control

Highly adaptable

Tower Crane Load Moment and Anti-collision

Visualized Monitoring

Improved Construction Efficiency

Slewing Reducer for Tower Crane

Best quality based on…