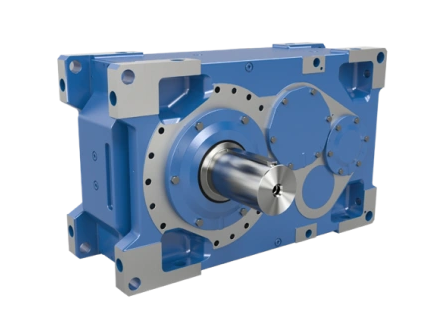

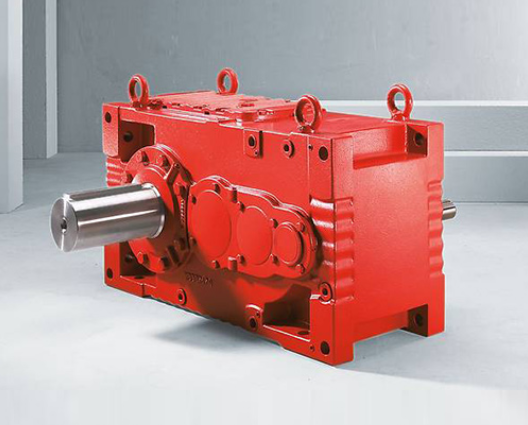

Nord gearbox is one of the popular construction hoist drive parts but it isn’t only used for construction hoists. This paper aims to provide a comprehensive overview of the installation and commissioning procedures associated with Nord gearboxes in construction settings.

1. Pre-installation Preparations of Nord Gearboxes

Before commencing the installation of a Nord gearbox in a construction setting, several essential preparations must be undertaken to ensure a smooth and successful process.

1.1 Site Requirements

- Adequate Space: The construction site must provide sufficient space to accommodate the gearbox, associated equipment, and personnel working on the installation. Consider factors such as clearance for lifting, maneuvering, and potential future maintenance.

- Level Surface: The foundation or mounting surface should be level and stable to prevent misalignment and excessive vibration. Any irregularities or unevenness must be corrected to ensure proper gearbox operation.

- Accessibility: Ensure easy access to the installation area for equipment, tools, and personnel. This includes providing clear pathways, removing obstructions, and considering any potential safety hazards.

1.2 Equipment Inspection

- Visual Inspection: Conduct a thorough visual inspection of the Nord gearbox to identify any signs of damage, such as dents, cracks, or missing components, that may have occurred during transportation.

- Model and Specifications Verification: Cross-reference the gearbox’s model number, specifications, and accompanying documentation to confirm that it matches the requirements of the specific construction equipment or application.

- Component Integrity: Check the condition of all components, including shafts, couplings, seals, and bearings, to ensure that they are free from defects.

1.3 Tool and Material Preparation

- Specialized Tools: Assemble the necessary tools for the installation, which may include various wrenches, torque wrenches, lifting equipment (e.g., cranes, hoists), alignment tools, and measuring instruments.

- Auxiliary Materials: Gather the required auxiliary materials, such as:

| Fasteners | Bolts, nuts, and washers of appropriate size and strength. |

| Gaskets and Seals | To ensure a leak-proof and dust-proof installation, prepare gaskets and seals compatible with the gearbox and operating conditions. |

| Lubricants | Select the appropriate lubricants for the gearbox and its components, following the manufacturer’s recommendations. |

| Marking Tools | For precise alignment and positioning. |

| Cleaning Supplies | To remove dirt, grease, or other contaminants from the installation area and components. |

2. Installation Process of Nord Gearboxes

2.1 Foundation Installation

- Mounting: Securely fasten the gearbox to the foundation of the construction equipment using appropriate mounting hardware. The mounting method will depend on the specific gearbox design and the foundation’s characteristics.

- Bolting Requirements: Adhere to the manufacturer’s recommended bolt tightening torque values and sequence. Incorrect tightening can lead to stress concentrations, leaks, or misalignment.

- Alignment: Ensure that the gearbox is accurately aligned with the foundation to minimize vibration and stress on the components. Use alignment tools, such as laser alignment systems, to achieve precise alignment.

2.2 Connection of Components

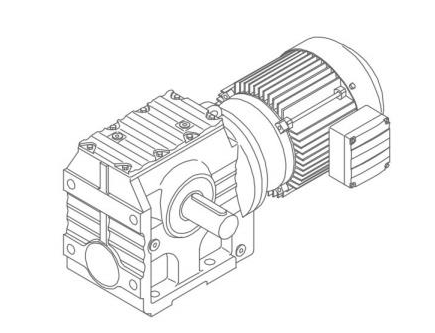

- Power Source: Connect the gearbox to the power source, such as an electric motor, using a suitable coupling. The coupling must be properly sized and aligned to transmit torque smoothly and efficiently.

- Coupling Installation: When installing the coupling, pay attention to the following:

- Balance: Ensure that the coupling is dynamically balanced to minimize vibration.

- Alignment: Align the coupling halves precisely to prevent misalignment-induced wear and damage.

- Fasteners: Use the correct fasteners and torque them to the specified values.

- Output Shaft Connection: Connect the gearbox output shaft to the driven component, such as a conveyor or a pump, using a suitable coupling or shaft. Maintain strict concentricity to prevent excessive wear and vibration.

2.3 Piping Connections (if applicable)

- Fluid Lines: Connect oil or coolant lines to the gearbox according to the manufacturer’s instructions. Use appropriate fittings, hoses, and clamps to ensure a leak-free connection.

- Sealing: Apply a suitable sealant to the threaded connections and gaskets to prevent leaks. Over-tightening can damage the threads or gaskets, so apply a moderate amount of torque.

- Routing: Route the pipes in a way that minimizes stress on the connections and prevents interference with other components.

3. Commissioning Process of Nord Gearboxes

3.1 Initial Inspection

- Visual Inspection: Conduct a thorough visual inspection of the installed gearbox to ensure that there are no visible damages, misalignments, or other abnormalities.

- Fastener Verification: Double-check all connections and fasteners to confirm that they are tightened to the specified torque values and that there are no loose components.

3.2 Fluid Filling (if applicable)

- Fluid Type and Quantity: Fill the gearbox with the specified type and quantity of lubricant according to the manufacturer’s recommendations. The correct lubricant is essential for optimal performance and longevity.

- Level Check: Use the dipstick or sight glass to verify that the fluid level is within the recommended range. An incorrect fluid level can lead to overheating, cavitation, or premature wear.

3.3 No-Load Test

- Startup: Start the construction equipment without applying any load to the gearbox.

- Observation: Listen for any unusual noises, vibrations, or grinding sounds. Monitor the gearbox temperature to ensure that it remains within normal operating limits.

- Leakage: Inspect all connections and seals for any signs of leakage.

3.4 Load Testing

- Gradual Loading: Gradually increase the load on the gearbox to assess its performance under various operating conditions.

- Parameter Monitoring: Monitor key performance parameters, such as:

| Speed | Ensure that the gearbox output speed matches the design specifications. |

| Torque | Verify that the gearbox can deliver the required torque without overheating or overloading. |

| Temperature | Monitor the gearbox temperature to ensure it remains within safe operating limits. |

| Vibration | Check for excessive vibration, which could indicate misalignment, imbalance, or other issues. |

| Noise | Listen for any unusual noises that may signal a problem. |

- Performance Evaluation: Compare the measured performance parameters to the manufacturer’s specifications and expected values. If any deviations are observed, investigate the root cause and take corrective action.

4. Safety Precautions During Installation and Commissioning

Safety should be a top priority throughout the installation and commissioning of a Nord gearbox just like every step for the reliable operation of it. Adhering to the following safety precautions can help prevent injuries to personnel and damage to equipment.

4.1 Personnel Safety

- Personal Protective Equipment (PPE): Ensure that all personnel involved in the installation process wear appropriate PPE, including safety helmets, safety glasses, gloves, and steel-toed boots.

- Lockout/Tagout Procedures: Before working on any equipment, follow established lockout/tagout procedures to prevent unexpected start-ups.

- Confined Space Entry: If working in confined spaces, such as within equipment enclosures, follow the appropriate safety procedures and ensure adequate ventilation.

- Lifting Safety: When lifting heavy components, use proper lifting equipment and techniques to prevent injuries.

- Electrical Safety: Exercise caution when working with electrical components. Use insulated tools and follow electrical safety standards.

- Training: Ensure that all personnel involved in the installation are properly trained and qualified to perform their tasks.

4.2 Equipment Safety

- Grounding: Ensure that all equipment is properly grounded to prevent electrical shock and equipment damage.

- Alignment: Proper alignment of the gearbox and connected components is crucial to prevent excessive vibration and wear.

- Overloading: Avoid overloading the gearbox beyond its rated capacity.

- Lubrication: Use the recommended lubricants and follow the manufacturer’s guidelines for lubrication.

- Inspection: Conduct regular inspections of the gearbox and its components for any signs of wear, damage, or misalignment.

- Emergency Stop: Ensure that an emergency stop button is readily accessible and in good working condition.

Key Takeaways from This Discussion:

| Pre-installation Planning | Careful planning is essential to ensure that the installation site is adequately prepared and that all necessary tools, equipment, and materials are available. |

| Accurate Alignment | Precise alignment of the gearbox and connected components is crucial to prevent vibration, wear, and premature failure. |

| Proper Torqueing | Adhering to the specified torque values for fasteners is essential to prevent loosening and damage. |

| Leak-Free Connections | All connections, including fluid lines and seals, must be leak-free to prevent contamination and operational issues. |

| Thorough Inspection | A comprehensive inspection should be conducted after installation and before commissioning to identify any potential problems. |

| Load Testing | Load testing is essential to verify that the gearbox can meet the required performance specifications. |

| Safety First | Safety should be a top priority throughout the entire installation and commissioning process. |

Contact the construction hoist equipment and part supplier CPTC for more information.

Related Products

ABB Inverter

Green and environmentally friendly;

Customized services.

Nord Motor & Nord Gearbox

Quality assurance

Rich products

CPTC supply

Yaskawa Inverter

Customizable Options;

Precise Speed Control;

Yaskawa inverter & Yaskawa inverter…