Construction hoists, indispensable tools in the modern building industry, are responsible for lifting heavy loads, materials, and personnel to various heights during construction projects. These complex machines rely on a sophisticated system of gears to achieve their essential functions. Among these gears, the worm gear shaft stands out as a crucial component, providing the necessary torque and speed reduction to power the hoist’s lifting mechanisms.

This article will introduce the intricacies of worm gear shafts in construction hoists, exploring their structure, function, and the vital role they play in ensuring the safe and efficient operation of these essential pieces of equipment. By understanding the principles behind worm gear shafts, we can appreciate their significance in the construction industry and the engineering marvels they contribute to.

What Is the Structure of a Worm Gear Shaft?

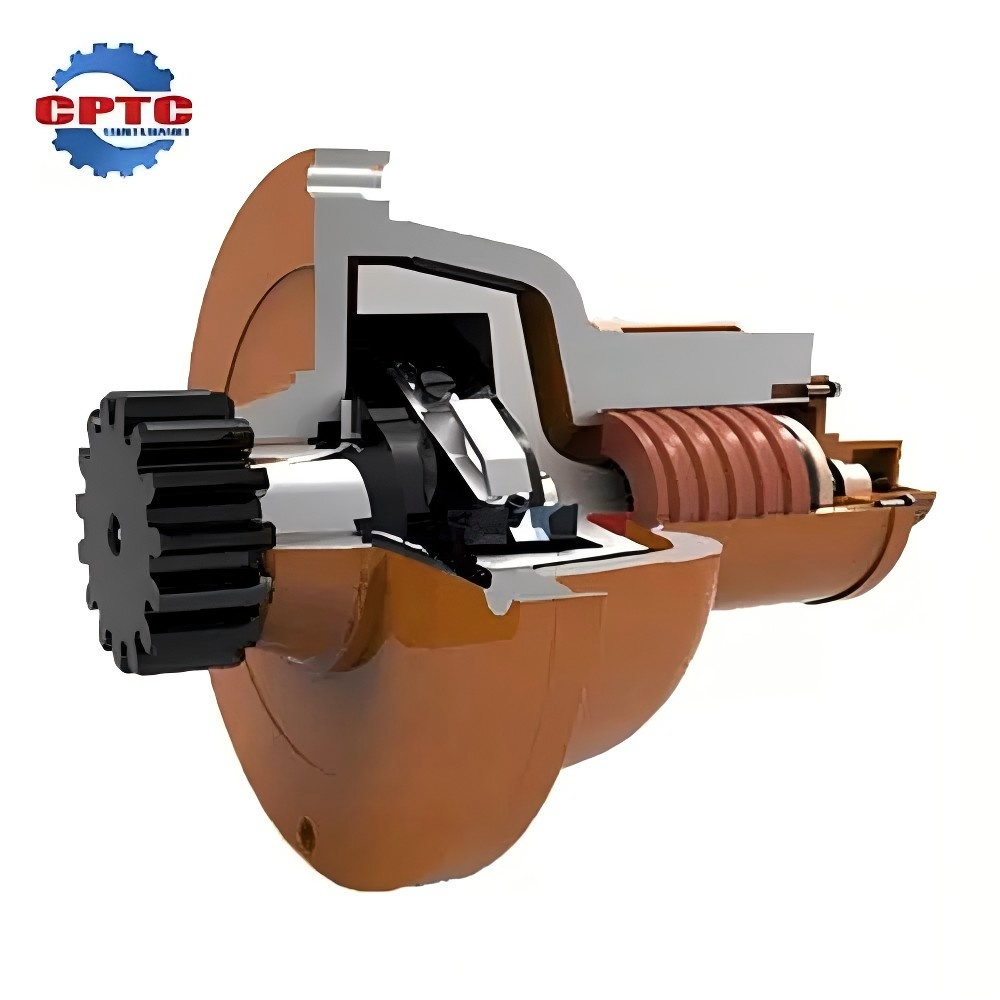

A worm gear shaft is a critical component in construction hoists, comprising two essential elements:

| Worm | The worm is a helical gear with a thread-like profile, resembling a screw. It is mounted on the worm shaft and engages with the worm wheel. The worm’s helical shape allows for a smooth and efficient transfer of rotational motion. |

| Worm Wheel | The worm wheel is a spur gear with a high tooth count, resembling a conventional gear. It meshes with the worm, converting the rotational motion from the worm shaft to a lower speed but with a significantly increased torque. The high tooth count of the worm wheel further amplifies the torque multiplication effect. |

The worm shaft itself is typically constructed from high-strength steel, ensuring its durability and ability to withstand the heavy loads imposed by construction hoists. To minimize friction and maintain precise alignment between the worm and worm wheel, the worm shaft is often supported by bearings. These bearings provide smooth rotation and reduce wear, contributing to the overall longevity and efficiency of the worm gear mechanism.

How Does a Worm Gear Shaft Function in Construction Hoists?

The worm gear shaft plays a pivotal role in the operation of construction hoists, serving several critical functions:

- Torque Multiplication: One of the primary advantages of worm gear shafts is their ability to significantly multiply torque. This means that the hoist can generate a substantial amount of force, allowing it to lift heavy loads with relative ease. This is particularly important in construction applications where the hoist is often required to move large and heavy materials.

- Speed Reduction: In addition to torque multiplication, worm gear shafts also provide a significant speed reduction. This means that the rotational speed of the hoist’s motor is reduced, resulting in a slower but more powerful lifting action. This is essential for ensuring controlled and precise movements, especially when lifting delicate or sensitive loads.

- Self-Locking: A crucial safety feature of worm gear drives is their self-locking property. This means that the hoist will not move downward under its own weight when the power is off. This prevents accidental lowering of the load, ensuring the safety of workers and equipment.

- Balanced Performance: While worm gear drives may be slightly less efficient than spur gear drives in terms of energy transmission, they offer a well-balanced combination of torque multiplication, speed reduction, and self-locking properties. This makes them ideal for construction hoist applications, where these characteristics are essential for safe and effective operation.

Why Is the Maintenance of a Worm Gear Shaft so Important?

The proper maintenance of the worm gear shaft is paramount to the safe and reliable operation of a construction hoist. Regular inspections, lubrication, and adjustments are essential to prevent wear, reduce downtime, and extend the lifespan of this critical component.

What Are the Key Maintenance Tasks for a Worm Gear Shaft?

- Regular Inspections: Conduct thorough inspections of the worm and worm wheel to identify any signs of wear, damage, or misalignment. This includes checking for chipped or cracked teeth, excessive wear on the worm’s threads, and any evidence of binding or resistance during rotation. Early detection of these issues can prevent more serious problems and costly repairs.

- Lubrication: Proper lubrication is crucial to reduce friction and prevent premature wear on the worm gear shaft and its components. Use the recommended lubricant and apply it according to the manufacturer’s instructions. Regular lubrication will help maintain the smooth operation of the worm gear mechanism and prevent excessive heat buildup, which can lead to component failure.

- Tightening of Fasteners: Ensure that all bolts and fasteners are securely tightened to maintain proper alignment and stability. Loose fasteners can cause misalignment, vibration, and increased wear on the worm gear components. Periodically check the tightness of these fasteners and tighten them as needed.

- Component Replacement: If any components of the worm gear shaft, such as the worm or worm wheel, show significant wear or damage, they should be replaced promptly. Continuing to operate the hoist with worn or damaged components can lead to catastrophic failure, putting the safety of workers and the public at risk.

Essential Worm Gear Shaft

The worm gear shaft provides essential torque multiplication, speed reduction, and self-locking properties as an indispensable component in construction hoists. Its robust structure and reliable performance contribute significantly to the safe and efficient operation of these essential pieces of equipment. We should take proper maintenance of the worm gear shaft to ensure its longevity and prevent costly equipment failures. And be sure to take regular inspections, lubrication, and component replacement to minimize downtime and protect the safety of workers and the public. Invest in the care and maintenance of worm gear shafts and consult with professional construction hoist manufacturer when occurring any question so that you can maximize your equipment’s lifespan and ensure the successful completion of their projects.

Related Products

Construction Hoist Floor Calling System

Effortless installation

Reliable performance over extended ranges

Accommodates…

SRIBS Safety Device

The safety switch’s action is…

Construction Hoist Gearbox and Parts

Trademark: CPTC, GJJ, PET, BAODA

Passenger…

ABB Inverter

Green and environmentally friendly;

Customized services.