Construction platforms are elevated work areas that pose significant hazards to workers. These hazards include slips, trips, and falls from height, which can result in severe injuries or fatalities. Safety ropes serve as essential fall protection equipment, acting as a lifeline to prevent workers from free-falling if they lose their balance or footing. By attaching themselves to a secure anchorage point, workers can confidently perform their tasks knowing that they are tethered to a safety system.

The Dangers Associated with Construction Platforms

Construction platforms represent a significant risk to worker safety due to their inherent nature. Operating at elevated heights introduces a multitude of hazards that can have severe consequences.

Fall Hazards

The elevated position of construction platforms poses the most immediate and significant threat. Workers are constantly at risk of falling due to various factors. Loss of balance, whether caused by sudden movements, uneven surfaces, or strong winds, can easily lead to a fall. Equipment failures, such as the collapse of scaffolding or the breaking of safety harnesses, can also result in catastrophic falls. Furthermore, inadequate fall protection systems, such as missing or improperly installed safety nets or guardrails, significantly increase the likelihood of serious injuries or fatalities.

Struck-by Hazards

Workers on construction platforms are constantly exposed to the risk of being struck by falling objects. Tools, such as hammers, wrenches, and power tools, can easily slip from grasp and fall to lower levels. Construction materials, including bricks, concrete blocks, and lumber, also pose a significant threat if not properly secured and handled. Debris, such as loose nails, screws, and pieces of metal, can also cause serious injuries if they strike a worker.

Other Hazards

Beyond the immediate risks of falls and struck-by hazards, construction platforms present a range of other dangers. Structural instability, such as the weakening of scaffolding or the failure of support beams, can lead to catastrophic collapses. Electrical hazards, such as contact with live wires or faulty equipment, pose a serious risk of electrocution. Exposure to environmental hazards, such as extreme weather conditions (high winds, heavy rain, and extreme temperatures), can increase the risk of accidents and injuries. Furthermore, exposure to hazardous materials, such as asbestos and lead, can have long-term health consequences for workers.

The Importance of Safety Ropes on Construction Platforms

Safety ropes are an indispensable component of any comprehensive safety program on construction platforms. They play a critical role in protecting workers from the inherent hazards associated with working at elevated heights.

Fall Prevention

Perhaps the most crucial function of safety ropes is their ability to prevent catastrophic falls. When working on elevated structures, the risk of slips, trips, and falls is ever-present. Even minor incidents can have devastating consequences. Safety ropes act as a crucial last line of defense. In the event of a sudden loss of balance, a slip on a wet surface, or a collapse of a temporary structure, the safety rope will arrest the fall, preventing the worker from plummeting to the ground. This crucial intervention can significantly reduce the severity of injuries, potentially saving lives.

Confined Work Space

Beyond their fall arrest capabilities, safety ropes can be effectively utilized to create confined work spaces, thereby enhancing worker safety. By strategically positioning anchor points and utilizing appropriate safety lines, workers can be restricted to specific areas within the platform. This is particularly crucial when working near edges, open shafts, or other hazardous areas. By limiting movement to designated safe zones, the risk of accidental falls or encounters with other hazards is significantly reduced.

Psychological Safety

The presence of a reliable safety rope system has a profound impact on worker psychology. Knowing that they are tethered to a robust and dependable system provides a significant sense of security. This psychological safety allows workers to focus on their tasks with greater confidence and reduced anxiety. The constant fear of falling can be a significant distraction, impacting productivity and increasing the risk of errors. By mitigating this fear, safety ropes contribute to a more focused and efficient work environment.

Proper Use and Maintenance of Safety Ropes

To ensure the effectiveness of safety ropes on construction platforms and maximize worker safety, adherence to specific use and maintenance requirements is paramount. There are some key points you need to pay attention to. If you want to know more about improving the performance of safety ropes, you can click to read another article: Maximizing Safety Rope Performance: A Guide.

Correct Wear

Proper usage begins with comprehensive training. Workers must receive thorough instruction on the correct techniques for wearing and connecting safety ropes. This includes selecting the appropriate type of rope for the specific task, identifying and utilizing designated anchor points, and ensuring proper connection to the harness. The connection points must be carefully inspected for any signs of wear, damage, or defects. Loose connections, frayed ropes, or improperly installed hardware can significantly compromise the effectiveness of the safety system and increase the risk of injury.

Regular Inspection

Regular inspections are crucial to identify and address potential issues before they can lead to accidents. Safety ropes should be inspected regularly for signs of wear and tear, such as cuts, abrasions, fraying, or discoloration. Exposure to harsh weather conditions, chemicals, and UV radiation can weaken the rope’s integrity. Any signs of damage or deterioration should be addressed immediately. Damaged ropes must be removed from service and replaced with new ones.

Maintenance

In addition to regular inspections, a routine maintenance schedule should be implemented. This may include cleaning the ropes to remove dirt and debris, and applying appropriate lubricants to maintain flexibility and prevent stiffness. The frequency and type of maintenance will vary depending on the specific type of rope, the working environment, and the manufacturer’s recommendations.

Integration with Other Safety Measures

It is crucial to understand that safety ropes are not an isolated safety measure. They must be integrated into a comprehensive safety system that includes other critical elements. This may include the use of safety harnesses, which provide a secure connection point for the rope, as well as the use of safety nets, which can further mitigate the impact of a fall. Guardrails and other physical barriers also play a crucial role in preventing falls and should be used in conjunction with safety ropes whenever possible.

Safeguarding Workers on Platforms

Safety ropes are an indispensable component of any construction platform safety system. To ensure the safety of workers, it is imperative that construction companies and workers prioritize the proper use, inspection, and maintenance of safety ropes. You can choose the CPTC safety ropes so that you can significantly reduce the risk of falls and create a safer working environment for all.

Related Products

Hoist Gearbox

Stable and reliable operation, secure

High flexibility, adjustable speed

Wide range…

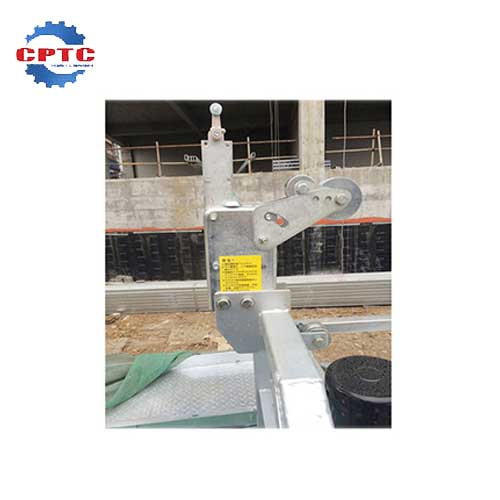

Limit Switch

Compact and Lightweight

Easy Installation

Suspended Platform Safety Lock

Easy to Operate and Use

Made…

Wire Rope

High Tensile Strength and Durability

Compliance with Safety…