Construction hoists, also known as construction elevators, are indispensable for vertical transportation of personnel and materials on building sites. These towering structures, while crucial for efficiency, present inherent safety risks, most notably the danger of falls. To mitigate this risk, construction hoists must be equipped with anti-fall safety devices. These devices act as a last line of defense, preventing catastrophic accidents and ensuring the well-being of workers and the integrity of materials.

Working Principle of Anti-fall Safety Devices

Anti-fall safety devices are complex mechanical systems designed to activate instantaneously and arrest the descent of a hoist cage in the event of a fall. They operate based on a combination of sophisticated mechanisms:

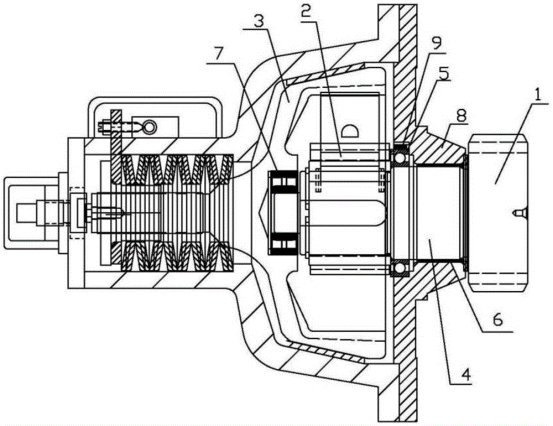

Centrifugal Trigger Mechanism: At the heart of the device is a centrifugal mechanism that continuously monitors the hoist cage’s speed. This mechanism is calibrated to a specific threshold. If the cage’s descent accelerates beyond this predetermined speed (indicating a potential fall), the centrifugal force triggers the braking system. This trigger is instantaneous, reacting to the abnormal acceleration before the situation escalates.

Progressive Braking Process: The braking process isn’t an abrupt, jarring halt. Instead, it’s designed to be progressive. Upon activation, the braking system applies increasing force, gradually decelerating the cage. This progressive braking minimizes the shock load on the cage, its occupants, and the materials being carried, preventing further injury or damage that could occur from a sudden stop.

Double Insurance Reset System: Once the braking system is activated and the cage is brought to a complete stop, a double insurance reset system engages. This system mechanically locks the cage in place, preventing any further movement. The “double insurance” aspect refers to redundant locking mechanisms, ensuring that the cage remains secured even if one mechanism were to fail. This system also allows for a controlled release of the braking mechanism by authorized personnel after the issue causing the fall has been addressed.

Installation Method of Anti-fall Safety Devices for Construction Hoists

The installation of anti-fall safety devices is a critical procedure, and there are two main installation methods: one is to install it on the main structure of the elevator, such as a safety device installed on the mast; the other is to install it on the suspension wire rope of the elevator, such as an anti-fall safety device installed between the upper and lower ends of the wire rope. Both installations require precision and adherence to the manufacturer’s specifications:

Manufacturer’s Instructions: Installation must be carried out strictly in accordance with the manufacturer’s instructions. These instructions provide detailed guidance on the correct installation location, fastening procedures, torque specifications, and alignment requirements.

Qualified Personnel: Only trained and certified personnel should be entrusted with the installation of these safety devices. They possess the necessary expertise to ensure that the device is installed correctly and functions as intended.

Testing and Verification: After installation, rigorous testing and verification are essential. This includes functional tests to confirm the device’s activation speed and braking performance, as well as load tests to ensure that the device can safely arrest the fully loaded cage.

Why Construction Hoists Need Anti-fall Safety Devices?

Construction hoists are commonly used in high-altitude construction, and there are certain safety risks in the process of using them. If they are not equipped with anti-fall safety devices, once there are failures in the hanging device, wire rope breakage, or brake failure, etc., it will cause a fall accident, resulting in casualties and property losses.

Protecting the Life Safety of Personnel

The most paramount reason is the protection of human life. Construction workers rely on hoists to access different levels of a building. A fall from such heights can be fatal. Anti-fall safety devices provide a critical safety net, preventing these falls and saving lives.

Protecting Materials and Equipment

Construction hoists transport valuable materials and equipment. A fall can result in significant financial losses due to damaged or destroyed items. Anti-fall safety devices minimize this risk, protecting investments and preventing project delays.

Complying with Laws and Regulations

Most jurisdictions have stringent safety regulations that mandate the use of anti-fall safety devices on construction hoists. Compliance with these regulations is not only a legal obligation but also a moral one, demonstrating a commitment to worker safety.

Daily Maintenance of Anti-fall Safety Devices

Anti-fall safety devices, like any mechanical system, require regular maintenance to ensure their continued effectiveness:

- Regular Inspections: Daily or pre-use inspections are crucial. These inspections should check for any signs of wear, damage, corrosion, or loose connections. Particular attention should be paid to the trigger mechanism, braking components, and locking system.

- Lubrication: Moving parts need regular lubrication to ensure smooth and reliable operation. The type of lubricant and the frequency of lubrication should adhere to the manufacturer’s recommendations.

- Functional Testing: Periodic functional testing is essential to verify the device’s performance. This includes simulating a fall scenario (under controlled conditions) to ensure that the device activates at the correct speed and brakes the cage effectively.

Precautions for Using Anti-fall Safety Devices

Safe operation of construction hoists and their anti-fall safety devices requires strict adherence to safety protocols:

- Anti-fall safety devices, whether in use or not, should be inspected and calibrated annually. They can only be used if they are within the validity period of the inspection.

- Users are not allowed to open the lead seal of the anti-fall device without authorization. Once the lead seal is damaged or falls off, the anti-fall device should be re-inspected and calibrated. Otherwise, the user unit will be held responsible for any accidents.

- The warranty period for newly purchased anti-fall devices under normal use is one year.

- The anti-fall device is a safety protection device for construction elevators, and the national standard stipulates that the service life is five years (calculated from the date of manufacture). Otherwise, the anti-fall device should be replaced.

- There is an oil filling hole on the outer shell of the anti-fall safety device in the cage. Add lubricating oil regularly according to the factory technical requirements, and it is strictly forbidden to add lubricating oil into the heat dissipation hole of the outer shell.

- After the anti-fall safety device is installed, be sure to pay attention to the meshing gap between the gear and the rack. If the meshing gap is too small, it may cause meshing interference and generate abnormal vibration and sound. If similar problems occur, they should be adjusted in time.

- The user must not remove the lead seal and adjust the position of the limit switch and the return ring retraction indicator pin of the anti-fall safety device without authorization.

CPTC Anti-fall Safety Device – Protecting Your Construction Safety

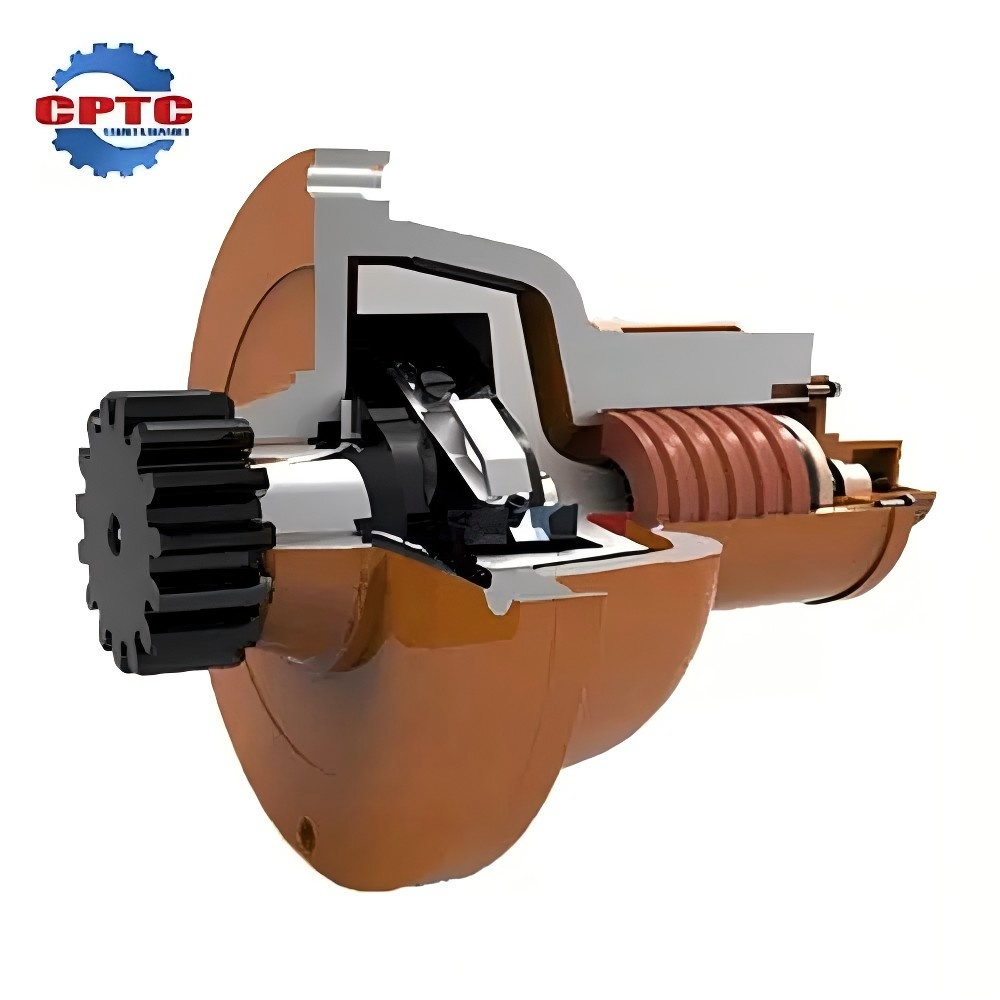

CPTC offers top-tier construction hoist anti-fall safety devices, including models SAJ30-1.2, SAJ40, SAJ50, SAJ60, and SAJ70. Our SAJ series pinion and cone progressive safety devices are critical for hoist safety, preventing overspeed and significantly reducing the risk of cage falls. These devices, developed by SRIBS, were recognized by the Ministry of Construction in 1989 for their innovative design, precise manufacturing, stable tripping speed, safety, reliability, smooth braking, and lightweight construction.

They were subsequently designated a high-tech product in the National “Eighth Five-Year Plan” and received the Shanghai Municipality Excellent New Product Achievement Award. Compatible with both domestic and international hoist brands like STROS and Alimak, our safety devices provide comprehensive protection for your construction operations.

Related Products

Construction Hoist Overload Indicator and Sensor

AC220V/50Hz

Overload Protection

High Capacity Relay

Compact Design

Durable Construction

SRIBS Safety Device

The safety switch’s action is…