Construction hoists are essential equipment in various fields such as building construction, bridge construction, and mining. They play a crucial role in the vertical transportation of personnel and materials, significantly improving construction efficiency and safety. As a critical component of construction hoists, the construction hoist gearbox is responsible for transmitting power and controlling the lifting speed and stability of the hoist. The performance and reliability of the construction hoist gearbox directly affect the overall operation of the construction hoist. Therefore, we need to study the necessity and importance of the construction hoist gearbox in ensuring the safe and efficient operation of construction projects.

The Role of the Construction Hoist Gearbox

The construction hoist gearbox is a critical component in construction hoists, responsible for power transmission and control. Let’s delve into its key functions:

1. Power Conversion

The construction hoist gearbox acts as a bridge between the motor and the hoist’s lifting mechanism. It expertly converts the motor’s output power to meet the specific demands of the hoist’s various operational states. For instance, during startup, the gearbox provides a high torque output to overcome inertia and initiate movement. When the hoist is ascending or descending, the gearbox adjusts the power output to maintain a steady speed. And when the hoist needs to stop, the gearbox facilitates a smooth deceleration to prevent abrupt jolting.

2. Speed Regulation

Construction hoists often require different speeds for different tasks. The construction hoist gearbox is designed to offer multiple gear ratios, enabling the hoist to operate at various speeds. This speed regulation is vital for both safety and efficiency. For example, when transporting personnel, a slower, more controlled speed is preferred to ensure safety. When moving materials, a higher speed might be employed to expedite the process. The gearbox’s ability to switch between these speeds allows the hoist to adapt to diverse construction scenarios.

3. Torque Control

Torque, the rotational force, is crucial for the stable operation of a construction hoist. The construction hoist gearbox plays a key role in managing torque. It ensures that the hoist can handle varying loads without any instability. When the hoist is carrying a heavy load, the gearbox provides the necessary torque to lift it smoothly. Conversely, when the load is light, the gearbox adjusts the torque output to prevent excessive speed or jerky movements. This precise torque control safeguards against overloading, which could lead to accidents, and also prevents situations where the hoist lacks the power to lift the load.

The Impact of Eliminating the Construction Hoist Gearbox

Imagine a construction hoist without a construction hoist gearbox. The consequences would be significant, affecting both the hoist’s performance and the safety of the construction site. Let’s explore the potential issues:

1. Power Transmission Problems

- Insufficient Power: The motor might not generate enough torque at low speeds to initiate movement, especially with a heavy load. This would result in the hoist struggling to start or even failing to lift the load.

- Excessive Power: At higher speeds, the motor’s output might be too high, causing the hoist to accelerate rapidly. This could lead to jerky movements, making it challenging to control the hoist and potentially damaging the lifting mechanism.

2. Lack of Speed Regulation

- Reduced Efficiency: The hoist might operate too slowly for certain tasks, such as transporting materials, leading to delays and impacting the overall construction schedule.

- Increased Waiting Time: Workers might have to wait longer for materials to be lifted, reducing their productivity.

- Compromised Safety: A fixed, high speed could be dangerous when transporting personnel, as it would be difficult to ensure a smooth and safe ride.

3. Risk of Hoist Failure

- Motor Damage: The motor could be subjected to excessive stress if it’s forced to provide high torque at low speeds, potentially leading to overheating or even burnout.

- Wear and Tear: The lack of torque control could cause jerky movements and vibrations, accelerating the wear and tear on the hoist’s components, especially the transmission parts.

- Structural Failure: In extreme cases, uncontrolled forces could lead to structural damage to the hoist or even cause it to fail, posing a severe safety hazard.

Summary

The construction hoist gearbox plays a vital role in power conversion, adapting the motor’s output to various operational needs. Its speed regulation function enables the hoist to operate at different speeds for diverse tasks, enhancing both safety and efficiency. Furthermore, the gearbox’s torque control capabilities ensure stable operation under varying loads, preventing overloads and ensuring smooth lifting. Given its crucial functions, the construction hoist gearbox must be given due attention in the design, manufacturing, and maintenance of construction hoists. A high-quality gearbox not only improves the hoist’s performance and extends its lifespan but also significantly contributes to the safety of construction operations. Therefore, it is essential to prioritize the selection and maintenance of the construction hoist gearbox to ensure the reliable and safe operation of construction hoists.

CPTC is one of the most famous construction hoist parts suppliers in China if you want to get more information about the construction hoist gearbox please contact us.

Related Products

Sew Motor & Sew Gearbox

SEW drive experts

Customized and efficient

Innovative and energy-saving

Schneider Inverter

Energy Efficiency

Schneider inverter & Schneider inverter card

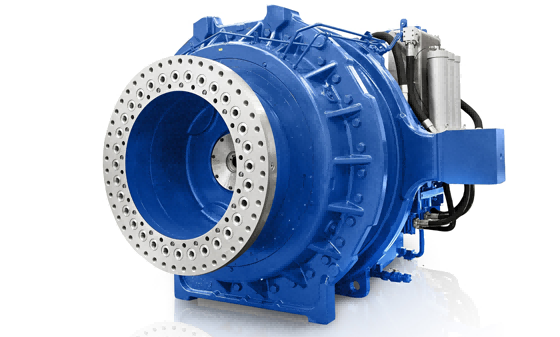

Construction Hoist Drive Device

The YZZl32M-4 motor

The core of the elevator drive and…

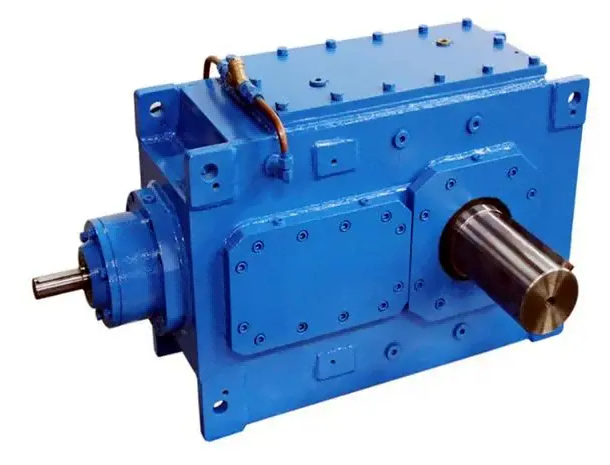

Nord Motor & Nord Gearbox

Quality assurance

Rich products

CPTC supply