Laser cutting offers micrometer-level precision, enabling the seamless creation of straight lines, arcs, and complex geometries in a single pass, eliminating the need for secondary processing and significantly enhancing product yield and consistency. This level of precision not only meets the stringent quality demands of modern industry but also unlocks the door to high-end customized production in the piping industry.

What is Laser Cutting Pipe?

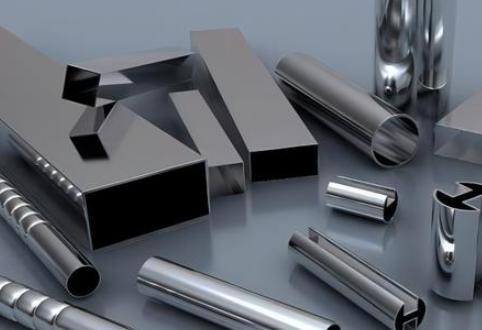

Laser cutting pipe is a modern manufacturing process that utilizes a high-powered laser beam to precisely cut through various pipe materials, including metal, plastic, and composite materials. This efficient and flexible technology involves directing a high-energy laser beam onto the pipe’s surface, causing the material to locally melt or vaporize, thereby achieving the desired cut. This method enables high-speed cutting while maintaining high precision and efficiency, producing pipes of different shapes, sizes, and thicknesses.

How Laser Cutting Pipe Works

Laser pipe cutting is a non-contact machining process that utilizes a high-energy laser beam to process tubular materials. The high energy of the laser beam causes the material on the pipe surface to melt and vaporize, thereby achieving the cutting. A laser pipe cutting machine primarily consists of a laser generator, an optical system, and a control system. The laser beam generated by the laser generator is modulated and amplified, then focused onto a very small spot through optical components such as lenses and mirrors. The energy at this spot is highly concentrated, reaching extremely high temperatures. When the laser beam irradiates the pipe, the material on the pipe surface melts and vaporizes due to the heat, and as the laser beam moves, a cutting path is gradually formed, ultimately completing the cutting of the entire pipe.

The laser pipe cutting process involves three steps: positioning, cutting, and unloading. First, the laser pipe cutting system positions the pipe on the cutting platform and performs automatic alignment. Then, the laser generator emits a high-energy density laser beam to cut the pipe. Finally, the unloading device removes the cut pipe.

What are the Advantages of Laser Cutting in Pipe Manufacturing?

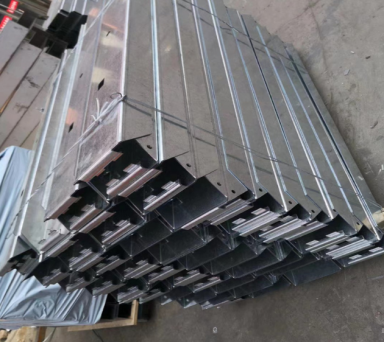

Laser cutting can be used to create openings, cut seams, and contour cut on the surface of pipes. Stainless steel pipes, steel products, and aluminum alloy pipes can be cut into various shapes, including round holes, square holes, and irregular patterns. The cutting thickness can reach approximately 5mm. The cutting speed is fast, and the equipment has high precision.

Laser cutting offers numerous advantages that make it a superior choice for pipe production:

High Precision:

Laser cutting employs the same fixturing system and programming software, ensuring exceptional accuracy and precision for pipe cutting. This guarantees that the cut pipes meet exact specifications and is suitable for processing various pipe shapes. With minimal material waste due to the smooth and burr-free cuts, laser cutting maximizes material utilization, reduces costs, and minimizes environmental impact.

High Efficiency:

Laser cutting is a rapid process capable of cutting a large volume of pipes in a short period, significantly improving production efficiency and reducing lead time. Laser cutting machines are highly automated, with cutting speeds hundreds of times faster than traditional manual cutting, making them ideal for large-scale production.

Flexibility:

Laser cutting can handle pipes of various shapes and sizes, allowing designers to create intricate designs and meet customized requirements. This enables tailored and innovative pipe production. The technology can cut a wide range of materials, including stainless steel, carbon steel, aluminum, and titanium.

Environmental Protection:

Laser cutting is a noise-free and pollution-free process, making it an environmentally friendly manufacturing method that aligns with modern industrial trends. By minimizing material waste, it contributes to more sustainable manufacturing practices. Laser cutting produces no harmful substances, making it gentle on the environment.

Cost Saving:

Through automation, laser pipe cutting machines can automatically feed and cut tubes, reducing labor requirements. This significantly increases production efficiency and leads to lower labor costs while saving material.

Customizable:

Laser pipe cutting machines can be customized to meet specific material and cutting requirements, enabling tailored solutions for diverse customer needs. These machines support a variety of functional modules, such as automatic loading and unloading systems, bevel cutting, and weld seam recognition. This technology facilitates rapid prototyping and testing of new pipe designs.

Application Scenarios of Different Types of Laser Cutting Pipes

On the stage of modern industrial manufacturing, laser pipe cutting technology has become a powerful tool for many enterprises thanks to its high precision, efficiency, and flexibility. Laser pipe cutting machines are widely used to cut a variety of materials, including metals and plastics.

Metal Pipes:

- Stainless Steel Pipes: Used in food processing, chemical processing, and pharmaceutical industries due to their corrosion resistance and durability.

- Carbon Steel Pipes: Widely used in construction, automotive, and shipbuilding industries for their strength and versatility.

- Aluminum Pipes: Lightweight and corrosion-resistant, ideal for aerospace, automotive, and marine applications.

Plastic Pipes:

- PVC Pipes: Used in plumbing, irrigation, and drainage systems due to their affordability and durability.

- PE Pipes: Widely used in gas and water distribution systems for their flexibility and resistance to corrosion.

- PP Pipes: Ideal for chemical processing and wastewater treatment due to their high temperature resistance and chemical resistance.

Composite Pipes:

- Carbon Fiber Pipes: High-strength and lightweight, used in aerospace, automotive, and sporting goods industries.

- Fiberglass Pipes: Corrosion-resistant and durable, used in chemical processing, wastewater treatment, and oil and gas industries.

Final Thoughts

Laser pipe cutting services have become highly sought-after in modern industrial manufacturing due to their efficiency, precision, and quality assurance. With advanced laser cutting technology, we can quickly and accurately complete a variety of tube cutting tasks.

CPTC offers professional laser pipe cutting outsourcing services. Regardless of your specific requirements, our services will provide you with an exceptional solution, enhancing the efficiency and quality of your project.

Related Products

Mold Making by CNC

Mold manufacturing

High automation

Labor savings

Aluminium Casting

Custom manufacturing

Widely used

High stability

Design on Sample/Drawing

CAD, UG, SW

Design on Sample/Drawing

Mechanical Parts Welding

OEM with Samples or Drawings

Wide range of applications

High…