One indispensable tool that can significantly enhance efficiency, safety, and cost-effectiveness is the construction hoist providing a reliable and efficient means of vertical transportation. From transporting materials to moving workers between floors, hoist construction equipment offers numerous benefits that can elevate your project to new heights.

In this article, we will explore the various advantages of utilizing construction hoists, the different types available, and their common applications in the construction industry.

Benefits of Construction Hoists on Your Job Site

Construction hoists have become indispensable tools on modern construction sites due to their numerous advantages. Let’s delve deeper into how these machines contribute to increased productivity, reduced site congestion, enhanced safety, and ultimately, reduced costs.

1. Increased Productivity

- Streamlined Material Handling: Hoists eliminate the need for manual labor to transport materials vertically, significantly reducing the time and effort required. This allows workers to focus on more skilled tasks, boosting overall productivity.

- Continuous Workflow: By providing a dedicated vertical transportation system, hoists ensure a continuous flow of materials, minimizing downtime and accelerating project timelines.

- Reduced Labor Costs: With fewer workers needed for material handling, labor costs can be reduced.

2. Reduced Site Congestion

- Vertical Transportation: Hoists transport materials vertically, freeing up valuable floor space for other construction activities. This reduces the risk of accidents caused by congested work areas.

- Improved Site Organization: Hoists help maintain a well-organized construction site by providing a designated pathway for materials.

3. Enhanced Safety

- Reduced Risk of Falls: Hoists significantly reduce the risk of workers falling from heights, as materials are transported safely and efficiently.

- Minimized Manual Handling: By minimizing the need for manual handling of heavy loads, hoists reduce the risk of injuries caused by strain or accidents.

- Compliance with Safety Regulations: Hoists can be equipped with safety features that ensure compliance with industry safety standards, protecting workers and the general public.

4. Reduced Costs

- Long-Term Savings: While there is an initial investment in purchasing or renting a hoist, the long-term savings in terms of increased productivity, reduced labor costs, and fewer accidents often outweigh the upfront costs.

- Reduced Material Damage: Hoists handle materials carefully, reducing the risk of damage during transportation, which can lead to significant cost savings.

- Improved Project Scheduling: By accelerating project timelines, hoists can help avoid costly delays and penalties.

Three Main Types of Construction Hoists to Meet Different Project Needs

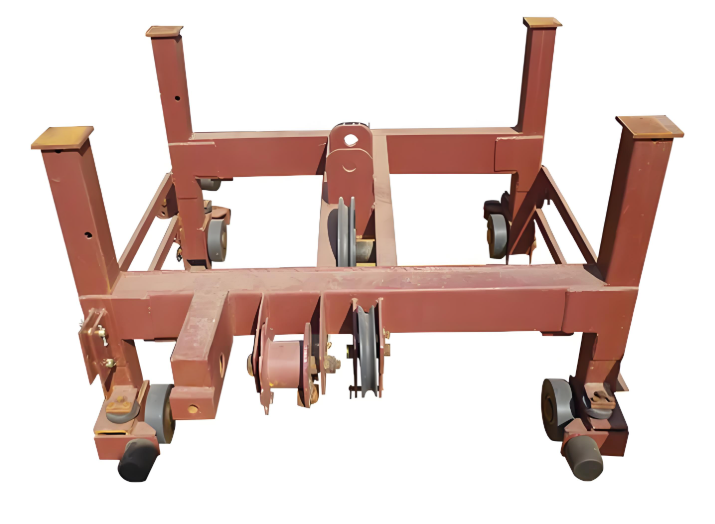

Construction hoists are essential tools in the modern construction industry, providing efficient and safe vertical transportation. Each project has unique requirements, and the choice of hoist depends on the specific needs of the job site. Let’s delve into the three primary types of construction hoists: people hoists, people and material hoists, and material-only hoists.

People Hoists

People Hoists are specifically designed to transport workers between different levels of a construction site. They are often enclosed and have features like safety gates, emergency stops, and communication systems to ensure the well-being of personnel. People hoists are commonly used in high-rise buildings, where workers need to access various floors for tasks such as finishing, installation, and maintenance. The enclosed design provides a controlled environment and protects workers from the elements and potential hazards.

People and Material Hoists

People and Material Hoists are versatile machines that can transport both workers and materials. You might also sound that some people call them construction hoist elevators. Construction hoist elevators offer flexibility for construction projects that require both the movement of workers and the transportation of materials such as tools, equipment, and building supplies. People and material hoists are a cost-effective solution as they eliminate the need for multiple hoists on a job site.

Material-Only Hoists

Material-only hoists, as well as construction material hoists, are designed exclusively for the vertical transportation of materials. They have an open platform or bucket and are often used for heavy-duty applications. Construction material hoists are ideal for projects that require the movement of large quantities of materials, such as concrete, steel beams, and masonry blocks. These hoists can handle significant loads and are often equipped with features like overload protection and automatic leveling systems to ensure safe operation.

Common Applications of Construction Hoists

Hoist construction equipment has become an indispensable tool in the modern construction industry, significantly enhancing efficiency and safety on various types of projects. These versatile machines find applications in a wide range of construction scenarios.

- High-Rise Buildings: Hoists are particularly essential in high-rise construction, where they are used to transport materials such as concrete, steel, and glass to upper floors. They also facilitate the movement of workers between different levels, ensuring a seamless workflow. The enclosed cabs of personnel hoists provide a safe and controlled environment for workers, especially when working at great heights.

- Bridges and Infrastructure: Construction hoists play a crucial role in the construction of bridges and other infrastructure projects. They are used to lift heavy structural components into place, such as girders, beams, and deck slabs. Hoists also aid in the installation of utilities, such as electrical cables and plumbing systems, on bridges and elevated structures.

- Industrial Facilities: Industrial facilities often require the installation of heavy equipment and machinery. Construction hoists are used to lift and position these large and bulky items with precision. They are also employed for maintenance and repair work, allowing workers to access elevated areas safely and efficiently.

- Renovation and Retrofit Projects: Even in renovation and retrofit projects, construction hoists find valuable applications. They can be used to remove old materials, install new windows or siding, and transport replacement parts to upper floors. Hoists provide a safe and efficient way to access hard-to-reach areas during renovation work.

- Specialized Applications: Beyond these common applications, construction hoists are also used in specialized projects such as wind turbine installation, offshore platform construction, and even in the film industry for set construction. Their versatility makes them suitable for a wide range of tasks that require vertical transportation.

Invest in Construction Hoists Now!

Construction hoists are more than just tools; they are essential assets that can significantly improve the efficiency, safety, and cost-effectiveness of your construction project. We’ve got the benefits they offer, the different types available, and their wide range of applications, so you can make informed decisions about incorporating construction material hoists or construction hoist elevators into your project planning.

Investing in construction hoists by choosing a reliable construction hoist supplier like CPTC can streamline operations, enhance safety, and ultimately, deliver a higher-quality project on time and within budget.

Related Products

How Much Does a Construction Hoist Cost?

Brake Disc for Tower Crane Motor

Rapid Reaction

High Durability