Construction hoists are indispensable tools that facilitate the efficient movement of heavy loads. At the heart of these machines lies a critical component: the crane gearbox. This intricate mechanism is responsible for converting high-speed, low-torque energy into low-speed, high-torque power, enabling cranes to lift and maneuver heavy loads with precision. The reliable operation of these gearboxes is paramount, as it directly impacts safety, productivity, and overall operational efficiency. This article delves into the critical factors that contribute to the reliable operation of hoist gearboxes, common problems that may arise, and effective maintenance strategies. Additionally, we will explore the advantages offered by Nord Gearboxes, a leading brand in the industry.

Why Is It Crucial to Ensure the Proper Operation of Hoist Gearboxes?

Safety First

- Preventing Catastrophic Failures: A malfunctioning hoist gearbox can lead to catastrophic consequences, such as dropped loads, which pose serious threats to personnel and equipment.

- Mitigating Risk: Ensuring the proper operation of hoist gearboxes is essential to minimize accidents and injuries in the workplace.

Optimizing Productivity

- Avoiding Costly Downtime: A breakdown in a hoist gearbox can bring an entire production line to a grinding halt, resulting in significant financial losses due to lost productivity and delayed shipments.

- Maximizing Efficiency: Well-maintained hoist gearboxes contribute to streamlined operations and increased output.

Energy Efficiency and Environmental Impact

- Conserving Resources: Efficient hoist gearboxes minimize energy consumption, leading to reduced operational costs and a smaller environmental footprint.

- Sustainable Operations: By optimizing energy usage, hoist gearboxes support sustainable practices and contribute to a greener future.

Precision and Quality Assurance

- Ensuring Accurate Lifting: In industries demanding precise lifting, such as manufacturing and assembly, hoist gearboxes play a crucial role in maintaining accuracy and preventing product damage.

- Upholding Quality Standards: Reliable hoist gearboxes contribute to the overall quality and consistency of products.

Regulatory Compliance

- Adhering to Safety Standards: Many industries are subject to stringent safety regulations governing the operation of lifting equipment. By ensuring the proper maintenance and operation of hoist gearboxes, organizations can demonstrate compliance with these regulations.

- Avoiding Legal and Financial Penalties: Failure to comply with safety regulations can result in hefty fines and legal repercussions.

Common Problems with Hoist Gearboxes and Their Solutions

| Causes | Consequences | Solutions | |

| Gear Wear | Excessive Load: Overloading the gearbox can lead to accelerated wear on gear teeth.Inadequate Lubrication: Insufficient or poor-quality lubrication can cause friction and wear. Misalignment: Improper alignment of shafts and gears can induce stress and premature wear. | Noise and Vibration: Worn gears produce excessive noise and vibration, indicating potential failure. Reduced Efficiency: Gear wear can lead to power loss and reduced efficiency. Potential Failure: Severe gear wear can result in catastrophic failure, such as gear tooth breakage. | Regular Inspection: Conduct regular visual inspections to identify signs of wear. Proper Lubrication: Use high-quality lubricants and adhere to recommended lubrication schedules. Alignment Checks: Periodically check and adjust shaft alignment to minimize stress. Load Monitoring: Monitor load levels to avoid overloading the gearbox. |

| Bearing Failure | Improper Installation: Incorrect installation can lead to premature bearing failure. Lack of Lubrication: Insufficient lubrication can cause excessive friction and heat. Contamination: Contaminants, such as dirt and debris, can damage bearing surfaces. | Increased Friction: Worn bearings can increase friction, leading to higher energy consumption and reduced efficiency. Noise and Vibration: Bearing failure can cause excessive noise and vibration. Reduced Gearbox Lifespan: Damaged bearings can accelerate the wear of other gearbox components. | Proper Installation: Ensure correct installation and alignment of bearings. Regular Lubrication: Adhere to recommended lubrication schedules and use high-quality lubricants. Contamination Control: Implement measures to prevent contamination, such as using seals and filters. Vibration Monitoring: Monitor vibration levels to detect early signs of bearing problems. |

| Oil Leaks | Damaged Seals: Worn or damaged seals can allow oil to leak. Loose Fittings: Loose fittings can lead to oil leakage. Corrosion: Corrosion of the gearbox housing or components can create leaks. | Reduced Lubrication: Oil leaks can compromise lubrication, leading to increased wear and friction. Contamination: Oil leaks can contaminate the working environment and damage equipment.Increased Maintenance Costs: Oil leaks require frequent maintenance and repair. | Regular Inspection: Inspect the gearbox for leaks during routine maintenance. Seal Replacement: Replace worn or damaged seals promptly. Tighten Fittings: Ensure that all fittings are securely tightened. Corrosion Prevention: Implement measures to prevent corrosion, such as using corrosion-resistant materials and protective coatings. |

| Overheating | Excessive Load: Overloading the gearbox can generate excessive heat. Inadequate Cooling: Insufficient cooling can lead to overheating. Lubrication Breakdown: Poor lubrication can cause excessive friction and heat. | Reduced Component Lifespan: High temperatures can accelerate the degradation of gearbox components. Increased Wear: Overheating can lead to increased wear and premature failure. Potential Fires: Severe overheating can pose a fire hazard. | Load Management: Avoid overloading the gearbox.Adequate Cooling: Ensure proper cooling, such as using fans or oil coolers. Regular Lubrication: Use high-quality lubricants and adhere to recommended lubrication schedules. Temperature Monitoring: Monitor gearbox temperatures to detect potential overheating issues. |

How to Properly Maintain a Hoist Gearbox?

- Regular Inspections: Conduct routine visual inspections to check for signs of wear, damage, or leaks.

- Proper Lubrication: Use the recommended type and quantity of lubricant, and adhere to the specified lubrication schedule.

- Temperature Monitoring: Monitor the gearbox’s operating temperature to ensure it remains within normal limits.

- Load Management: Avoid overloading the gearbox to prevent premature wear and damage.

- Alignment Checks: Periodically check and adjust shaft alignment to minimize stress and wear.

- Seal Replacement: Replace worn or damaged seals promptly to prevent oil leaks and contamination.

- Vibration Monitoring: Use vibration analysis to detect early signs of bearing wear or other internal problems.

- Professional Servicing: Schedule regular maintenance and repairs by qualified technicians.

This is just a brief summary of how to properly maintain the elevator gearbox. If you want to learn more about this, you can click here to learn more.

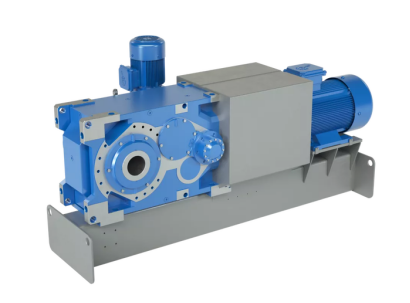

What Is the Advantage of Nord Gearbox over Other Hoist Gearboxes?

Nord produces various types of reducers, including worm gear reducers, planetary reducers, cycloid reducers, etc. Nord offers a wide range of reducer product lines to meet the needs of various industrial applications. Hoist Gearbox is one of the Nord Gearbox product lines, a reducer designed specifically for lifting equipment. As a well-known brand in the industry, Nord Gearbox’s hoist gearbox usually has the following advantages over other brands:

- Modular design: Nord Gearbox’s products usually adopt modular design, which makes the configuration flexible and can be customized according to different application requirements, thereby improving the adaptability of the equipment.

- High efficiency: By optimizing gear design and material selection, Nord Gearbox’s products usually have higher transmission efficiency and can reduce energy consumption.

- Long life: Using high-quality materials and advanced manufacturing processes, Nord Gearbox’s products have a long service life and can reduce maintenance costs.

- Low noise: By optimizing gear meshing and reducing vibration, Nord Gearbox’s products usually have lower noise levels and improve the working environment.

Upgrade Your Crane System: Contact CPTC Today

The reliable operation of crane gearboxes is essential for ensuring the safety, productivity, and efficiency of industrial operations. Understanding common problems to implement effective maintenance practices, and selecting high-quality gearboxes like those offered by Nord is an important way to optimize the overall operations. Construction hoist equipment and part supplier CPTC can provide you with high-quality Nord gearboxes and another hoist gearbox, you can contact us directly for more information.

Related Products

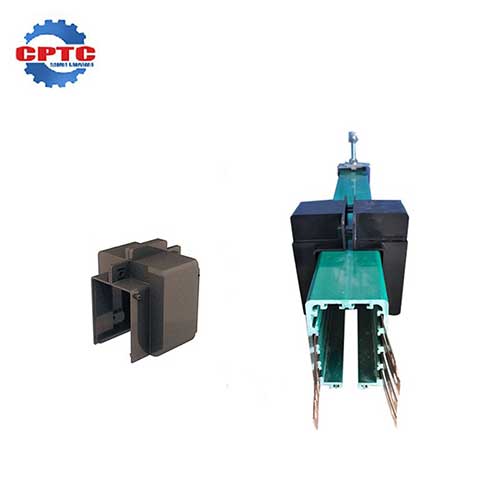

Conductor Bar System

Stability and high…

Schneider Inverter

Energy Efficiency

Schneider inverter & Schneider inverter card

Vechi Inverter

Green and environmentally friendly;

Customized services.

Heavy Duty Pipe Clamp & Heavy Duty Coupler

Alimak replacement parts/ Alimak compatible parts

Durability

OEM part…