The construction industry has witnessed significant advancements in recent years, with a particular focus on improving safety, efficiency, and productivity in high-rise projects. One such innovation that has revolutionized the way construction workers access hard-to-reach areas is the ZLP630 suspended platform. This versatile piece of equipment has become an indispensable tool for a wide range of construction and maintenance tasks. In this article, we will delve into the details of ZLP630 suspension platforms, exploring their components, applications, and safety precautions.

What is a ZLP630 Suspension Platform?

A ZLP630 suspended platform, often referred to as a suspended working platform or cradle, is a type of construction equipment designed to provide safe and efficient access to elevated work areas. It consists of a platform suspended from a building or structure by cables, enabling workers to perform various tasks at height. The designation “ZLP” refers to the specific type and model of the suspended platform, while “630” typically indicates its load capacity, although specific models may vary.

Specification of ZLP 630 Suspended Platform:

| Model | ZLP630 | |

| Suspended Platform | Rated Load | 630KG |

| 1m,2m,3m,1.5m,2.5m | Rated Lifting Speed | 9.3±0.5m/min |

| to the length made. | Length of Platform | 6000mm |

| In any Combination | Surface Proceeding | Aluminum;steel materials(Galvanized,Spraying) |

| Lifting Height | 100m | |

| Cable | 100m | |

| Max Lifting Height | 200m | |

| Steel Rope | 8.3mm | |

| Hoist | Power | 1.5KW*2 |

| Voltage | 380V, 50HZ, Three-Phase(standard) | |

| Safety Lock | Permission Force of Impact | 30KN |

| Locking Cable Angle | 3°~ 8° | |

| Suspension Mechanism | Front Beam Overhang | 1.3 ~ 1.5m ±0.26 |

| Support Adjustable Height | 1.44 ~ 2.14m ±0.26 | |

| Counter Weight | 1000KG | |

The Main Components of a ZLP630 Suspension Platform

The suspended platform system consists of several primary components: a suspension mechanism, a suspended platform, a hoist, safety locks, working steel ropes, safety steel ropes, and an electrical control system.To make it easier to transport, the platform is taken apart before it’s shipped and put together again at the construction site.

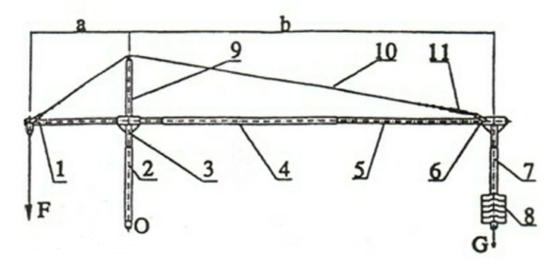

The suspension mechanism, installed at the top support of the building’s working face, is a steel structure that supports the weight of the suspended platform and its rated load via steel ropes. Two sets of suspension mechanisms are typically used. The force exerted by the suspension mechanism on the supporting structure of the building or structure should comply with the load-bearing requirements of the building structure.

The suspension mechanism comprises front beams, middle beams, rear beams, front brackets, rear brackets, upper columns, counterweights, reinforcing steel ropes, pins, and connecting sleeves. The front and rear beams can be telescoped within the middle beam for adjustment. To adapt to different working environments, the height of the front and rear beams can be adjusted by adjusting the height of the pins, with an adjustable range of 1.15-1.75 meters. The front and rear brackets are equipped with rollers for easy movement of the suspension mechanism. The number of counterweights is configured according to the specific model.

Suspended Platform

The suspended platform of the ZL630 model is a modular platform. The modular platform consists of front and rear railings, a bottom frame, and mounting brackets, which are connected by bolts. The standard section length is 2.5 meters or 2 meters.

The front and rear railings of the platform are welded from steel (aluminum) pipes. The front railing is 970mm high and is installed on the side facing the working area, while the rear railing is 1120mm high.

Hoist

The hoist used for the ZLP630 suspended platform is the LTD63 model.The electromagnetic braking device of the hoist motor can automatically engage in case of power failure or interruption, generating a braking torque to stop and support the suspended platform. In the event of a power failure or power outage, the lever of the manual descent device (located inside the hoist handle) can be rotated (inserted) into the lever of the electromagnetic brake (inside the motor fan cover) to open the brake, allowing the suspended platform to descend at a constant speed.

Safety Lock

To ensure safety, the safety lock should be tested before each use. Gently pull the safety rope to confirm it moves freely, then lock and unlock it multiple times. Next, forcefully pull the rope upward to activate the lock. Repeat this process several times to verify its functionality. The safety lock must be certified and used within its specified lifespan. Do not attempt to repair a faulty lock yourself; return it to the manufacturer for professional service. Failure to follow these procedures may void the manufacturer’s liability in case of accidents.

Working Steel Rope and Safety Steel Rope

Both the working steel rope and the safety steel rope are the main components that bear the load of the suspended platform, so there are strict requirements for the steel ropes used. The working steel rope and safety steel rope of the suspended platform both use galvanized steel ropes for suspended platforms, which have high strength and good rust resistance.

To prevent the rope end from loosening and to facilitate insertion into the hoist and safety lock, after the steel rope is cut to the selected length, both ends are specially processed, and the insertion end is welded and then ground into a conical bullet shape.

Applications of ZLP630 Suspension Platforms

The ZLP630 electric suspended platform is a modern tool used in construction, especially for building exteriors. It’s become very popular, especially with the growing number of tall buildings in world. It’s great for working on high-rise buildings, bridges, and chimneys:

- Exterior wall construction and renovation: Installing cladding, insulation, and other exterior finishes.

- Building maintenance: Cleaning, painting, and repairing building facades.

- Bridge, chimney, and dam maintenance: Inspecting and repairing these large structures.

- Shipbuilding: Welding, cleaning, and painting ship hulls.

- Installation of billboards and signage: Placing advertising and informational materials on buildings.

- Window cleaning: Cleaning large windows in high-rise buildings.

Precautions for Using a ZLP630 Suspension Platform

To ensure the safe and efficient operation of a ZLP630 suspension platform, several precautions must be taken:

Operator Training: All operators must receive adequate training to understand the equipment’s controls, safety features, and operating procedures. Only one person should control the suspended platform at a time. Before operation, all personnel in the basket should be alerted and it should be ensured that there are no obstacles above or below.

Regular Inspection:

Before operating the machine, the operator must conduct a thorough inspection of all items on the checklist and ensure that they meet the requirements. Regularly inspect the platform and its components for any signs of wear or damage.

- Hoist Steel Rope: No foreign objects such as sand, screws, nuts, or steel wires are allowed to enter the hoist steel rope inlet to avoid jamming the hoist, cutting the steel rope, and causing danger.

- Suspension Mechanism: Inspect the suspension mechanism. Ensure that all fasteners are securely connected, the counterweights and working steel ropes meet the technical requirements, and the safety locks are sensitive and reliable.

- Electrical System: Inspect the cable for damage, ensure that the plug is tightened, and the protective ground wire is reliable. Also, test whether the leakage protection switch of the distribution box inside the basket is sensitive and reliable.

- Control System: Test and check whether the functions of all pushbutton switches are sensitive and reliable. Also, check the performance of the motors of both hoists.

Load Limit: Do not exceed the rated load capacity of the platform. The rated load of the ZLP630 suspended platform is 630 kg.

Weather Conditions: Avoid using the platform in adverse weather conditions such as strong winds or heavy rain.

Safety Equipment: Operators must wear safety helmets and safety belts while working on the suspended platform. Alcohol consumption is strictly prohibited before operation.

Correct Installation: The platform must be installed correctly and securely to the building structure. If any part of the suspended platform is found to be faulty, it must not be used. Professional technicians should be invited for repair. Users are not allowed to disassemble or modify any part on their own.

Ascend to new heights of construction safety and efficiency with CPTC ZLP630 suspended platforms. These specialized construction machines are meticulously engineered to deliver unparalleled performance and reliability, making them the preferred choice for a wide range of high-rise applications.

Related Products

Suspended Platform Safety Lock

Easy to Operate and Use

Made…

Rope Presser

Wire rope protection

Strengthens wire rope

Improves safety…

Hoist Gearbox

Stable and reliable operation, secure

High flexibility, adjustable speed

Wide range…

Electromagnetic Brake Coil

Electromagnetic Brake Coil

High-speed, high-precision control

Quick-acting, precise control